SBR Latex Composite Modified Asphalt and Its Preparation Method

A technology of composite modified asphalt and styrene-butadiene latex, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of small improvement in high temperature resistance, pollution of the environment, and little increase in the softening point of asphalt, and achieve the goal of improving cohesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

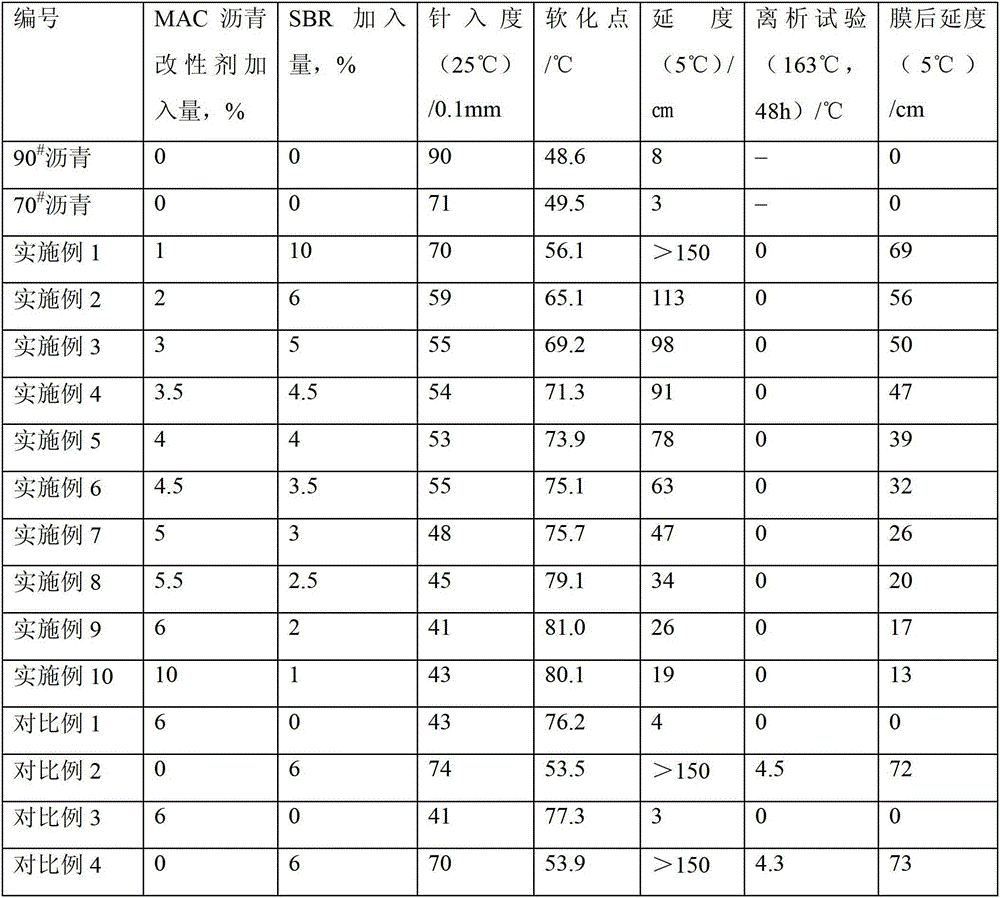

Embodiment 1

[0018] The 400g heavy traffic volume 90 # Heat the road asphalt to 170°C, then add 40g of SBR (equivalent to 181.82g of SBR emulsion, grade 1500, containing 22% SBR solid glue) slowly, start the stirring equipment to stir slowly, and continue heating to remove the water in the SBR emulsion After the water is removed, the temperature of the asphalt is slowly raised to 195°C, and then 4g of MAC asphalt modifier is added. Among them, the particle size of the selected MAC asphalt modifier is below 0.6mm, and the water content is between 0.4% and 1.2%. Between, the bulk density is 0.57-0.67g / cm 3 Between (the same below). Stir at a stirring speed of 550r / min for 0.6h until the modifier dissolves evenly, then measure the properties of the modified asphalt. See Table 1.

Embodiment 2

[0020] The 400g weight volume is 70 # Heat the road asphalt to 170°C, then add 24g of SBR (equivalent to 109.09g of SBR emulsion, grade 1500, containing 22% SBR solid glue) slowly, start the stirring equipment to stir slowly, and continue heating to remove the water in the SBR emulsion After the water was removed, the temperature of the asphalt was slowly raised to 195°C, then 8g of MAC asphalt modifier was added, and stirred at a stirring speed of 550r / min for 0.6h until the modifier was dissolved evenly, and the performance of the modified asphalt was measured. See Table 1.

Embodiment 3

[0022] The 400g weight volume is 70 # Heat the road asphalt to 170°C, then add 20g of SBR (equivalent to 90.91g of SBR emulsion, grade 1500, containing 22% SBR solid glue) slowly, start the stirring equipment to stir slowly, and continue heating to remove the water in the SBR emulsion After the water was removed, the temperature of the asphalt was slowly raised to 195°C, then 12g of MAC asphalt modifier was added, and stirred at a stirring speed of 550r / min for 0.6h until the modifier was dissolved evenly, and the performance of the modified asphalt was measured. See Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com