Method for preparing aromatic compounds employing catalytic cracking of industrial lignins

A technology for aromatic compounds and industrial lignin, applied in chemical instruments and methods, preparation of organic compounds, preparation of ethers, etc., can solve the problems of reduced catalyst activity, difficult catalytic hydrogenation reaction, poisoning of hydrogenation catalysts, etc. High conversion rate, the effect of alleviating the tension of petroleum resources and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

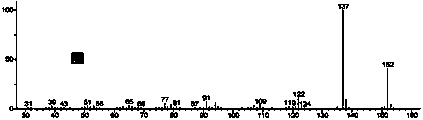

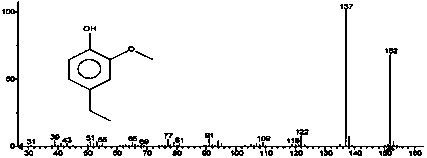

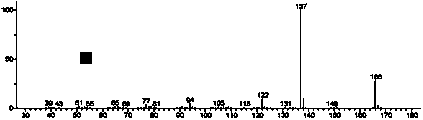

Image

Examples

Embodiment 1

[0027] Weigh 1 gram of nickel nitrate and dissolve it in 100 milliliters of water, add dried activated carbon (according to the loading amount of Ni is 8wt%), impregnate for 24 hours, and dry for 12 hours. Then, under the protection of nitrogen, hydrogen reduction was carried out at 450° C. in a quartz tube for 2 hours. Metal salts such as Ni, La, Ce, Al, Co, Fe, Cr, Zn and Cu used in preparing the catalyst are metal nitrates, Mo salts are ammonium molybdate, and Mn and Sn salts are metal chlorides.

Embodiment 2

[0029] The preparation process of the catalyst was carried out by the method of Example 1, except that different metal components and mass ratios and different supports were changed. See Table 1 for details.

[0030] Table 1

[0031]

[0032] Example 2

[0033] Mix 2g of sodium lignosulfonate and 120ml of ethylene glycol and stir at room temperature for 30 minutes, add 0.1g (calculated based on the total mass of metal) of the catalysts shown in the table below and transfer them to the autoclave. After replacing the air with nitrogen for 3-5 times, heat to 200 ° C, then fill with reaction gas, the partial pressure of hydrogen is 5MPa, stir rapidly, and the reaction starts. After reacting for 6 hours, the stirring was stopped, the temperature was lowered to room temperature, the hydrogen gas was evacuated, and a sample was taken for analysis. The qualitative analysis of the product was performed by gas chromatography-mass spectrometry, and the quantitative analysis was rea...

Embodiment 3

[0037] The catalytic cracking reaction of embodiment 3 sodium lignosulfonate

[0038] Mix 2g of sodium lignosulfonate and 120ml of solvent at room temperature and stir for 30 minutes, then add 0.1g (calculated based on the total mass of metal) of NiFe / ZrO with a metal loading of 10%. 2 The catalyst was transferred to the autoclave. After replacing the air with nitrogen for 3-5 times, heat to 200°C, then fill with reaction gas, hydrogen partial pressure is 5MPa, stir rapidly, and the reaction starts. After reacting for 6 hours, the stirring was stopped, the temperature was lowered to room temperature, the hydrogen was evacuated, and samples were taken for analysis. Analysis method is with embodiment 2.

[0039] table 3

[0040]

[0041]

[0042] It can be seen from the table that the reaction system with reducing ability, typically such as polyols and amides, can reduce the poisoned catalyst in situ, showing considerable activity, while in the system without reducing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com