Segmented oxygen supply self-circulation denitrification reactor

A reactor and self-circulation technology, applied in the field of biological denitrification reactors, can solve the problems of nitrite accumulation, limited process, and difficult regulation of substrate ratio, so as to improve denitrification efficiency, strengthen short-range nitrification, and overcome substrate ratio The effect of regulatory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

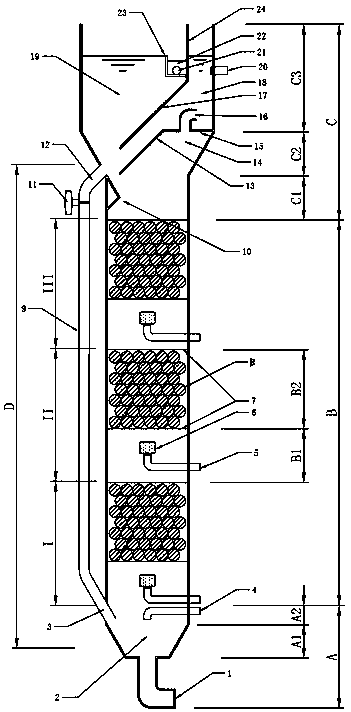

[0026] Such as figure 1 The body of the self-circulation denitrification reactor with segmental oxygen supply shown is equipped with water distribution area A, reaction area B, separation area C and circulation area D; the specific structure includes mud discharge pipe 1, water flow mixing distribution chamber 2, and reflux liquid input port 3. Water inlet pipe 4, air inlet pipe 5, aeration head 6, packing bracket 7, porous packing 8, return pipe 9, deflector 10, regulating valve 11, return liquid output port 12, slanted plate of the gas collection chamber 13, collecting Air chamber 14, top plate of air collection chamber 15, exhaust port of air collection chamber 16, bottom plate of sedimentation chamber and upper guide plate 17, degassing chamber 18, sedimentation chamber 19, scum discharge pipe 20, water outlet pipe 21, water outlet tank 22 , overflow weir 23, longitudinal septum 24;

[0027] The water distribution area A is located at the lower part of the reactor body, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com