A kind of method for preparing bulk nanocrystalline alloy material

A technology for nanocrystalline alloys and nanocrystalline materials is applied in the field of preparing bulk nanocrystalline alloy materials by using cold pressure welding technology, and can solve the problems of difficulty in preparing nanometer metals and alloy solids, difficulty in obtaining metal amorphous, and limited application scope, etc. Achieve low cost, prevent nanocrystal growth, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

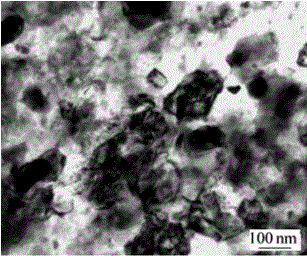

Image

Examples

Embodiment 1

[0019] This embodiment specifically implements a method for preparing bulk nanocrystalline aluminum alloy, wherein the aluminum alloy used is 7055, and the thickness of the desired nanocrystalline material is 10mm; the nanocrystalline 7055 aluminum alloy strip prepared by the melt rotation method Place it horizontally on the 7055 aluminum alloy material with a thickness of 5mm and a length and width of 20mm. The surface of the block alloy is flat and has been degreased and derusted in advance. The punch pressurizes cold welding, one welding spot follows the previous welding spot until the base material is fully welded; the positioning mold is made of die steel, the inner hole size section is 0.5mm×0.5mm, the height is 2.5mm, and the pre-loading pressure It is 40MPa; the cold punch is made of die steel, the end face size is 0.5mm×0.5mm, and the height is 3.0mm; the loading stress of pressurized cold welding is 2300MPa, and the loading duration is 0.5s; The position of the solde...

Embodiment 2

[0021] This embodiment specifically implements a method for preparing bulk nanocrystalline aluminum alloy, wherein the aluminum alloy used is 6061, and the thickness of the desired nanocrystalline material is 15mm; the nanocrystalline 6061 alloy strip prepared by the melt rotation method is horizontally Placed on the 6061 aluminum alloy material with a thickness of 10mm and a length and width of 25mm each. The surface of the block alloy is flat and has been degreased and derusted in advance. Pressure cold welding, one welding point follows the previous welding point until the block material is fully welded. Among them, the positioning die is made of die steel, the size of the inner hole is 2.0mm×2.0mm, the height is 4.0mm, and the preloading pressure is 50MPa; the cold punch is made of die steel, the end surface size is 2.0mm×2.0mm, the height 5.0mm; the loading stress of pressurized cold welding is 2000MPa, and the loading duration is 1.5s; the position of the last solder joi...

Embodiment 3

[0023] The present embodiment specifically implements a method for preparing bulk nanocrystalline titanium alloy, wherein the titanium alloy used is Ti6Al4V, and the thickness of the nanocrystalline material desired to be obtained is 12 mm; the nanocrystalline Ti6Al4V titanium alloy strip prepared by the melt rotation method Place it horizontally on the Ti6Al4V titanium alloy material with a thickness of 6mm and a length and width of 20mm each. The surface of the block alloy is flat and has been degreased and derusted in advance. Pressurized cold welding, one welding spot followed by the previous welding spot until the base material is fully welded; among them, the positioning mold is made of die steel, the inner hole size section is 1.0mm×1.0mm, the height is 3.5mm, and the pre-loading pressure 30MPa; the cold punch is made of die steel, the end face size is 1.0mm×1.0mm, and the height is 4.0mm; the loading stress of pressurized cold welding is 2500MPa, and the loading duratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com