Casting method for casting thin-walled investment casting steel parts

A casting molding and investment casting technology is applied in the casting field of thin-walled investment steel castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

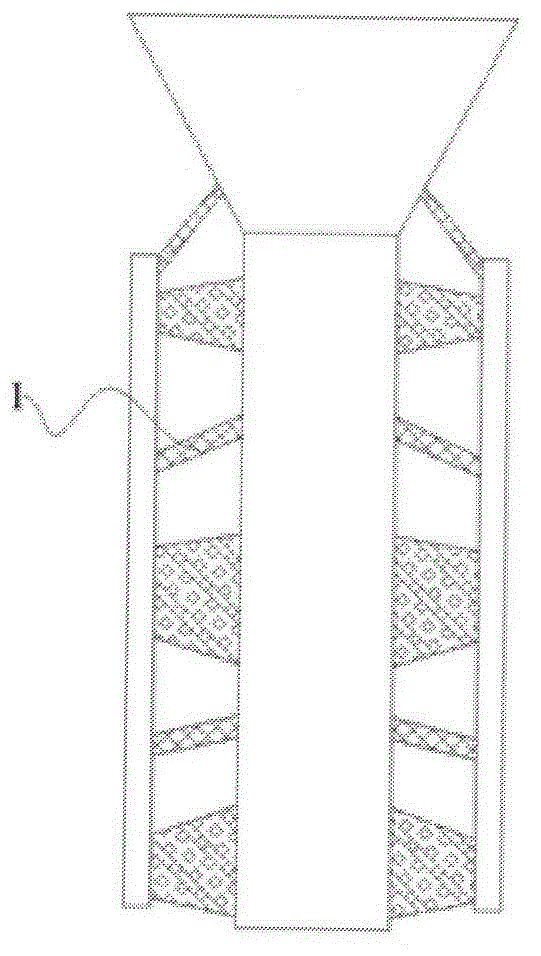

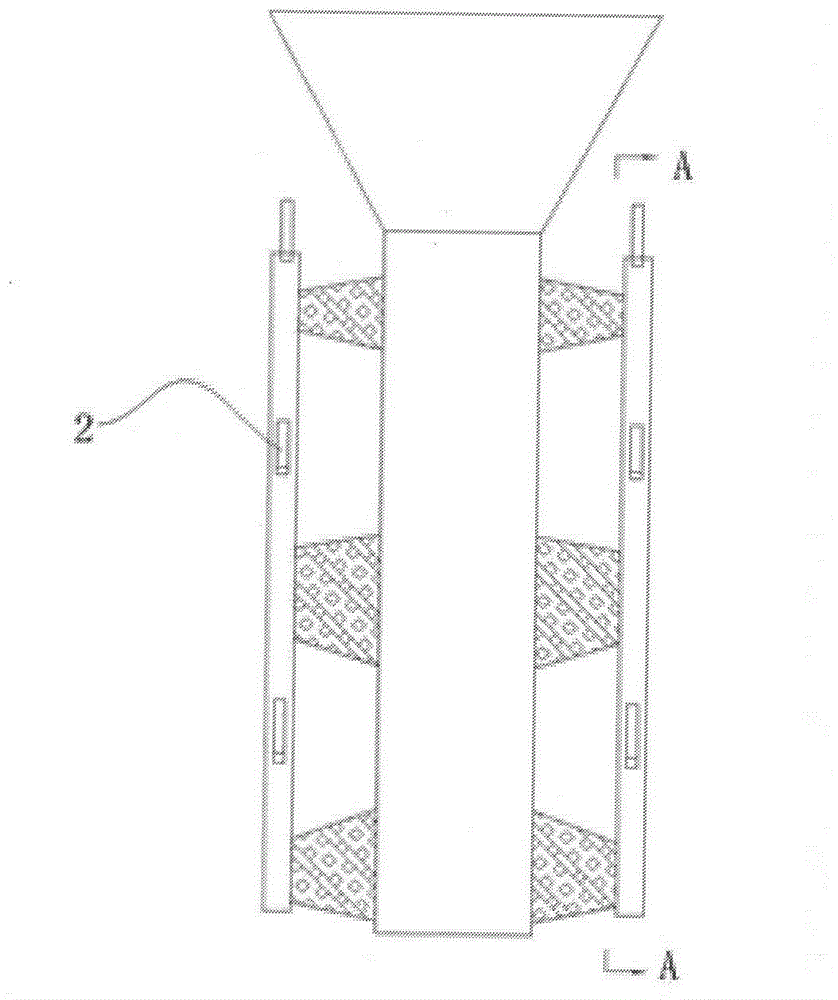

[0030] Such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the casting method of the thin-walled investment casting steel casting provided by the present embodiment includes the following steps:

[0031] a. First prepare a plurality of straight iron wires with a diameter of 0.5mm and a length of 50mm, and apply a layer of wax with a thickness of 0.1mm on the outer surface of the straight iron wires;

[0032] b. Then insert the straight iron wire in the previous step into the wax mold group 3 after the tree is assembled, and the insertion depth is 4mm;

[0033] c. Then dip the straight iron wire in the previous step with the wax mold group 3 into paint slurry and coat hanging sand;

[0034] d. After forming the mold shell 4 on the surface of the wax mold group 3, first destroy part of the mold shell 4 on the surface of the other end of the straight iron wire, extract the straight iron wire, and then dewax and roast;

[0035] e. When pouring molten steel at th...

Embodiment 2

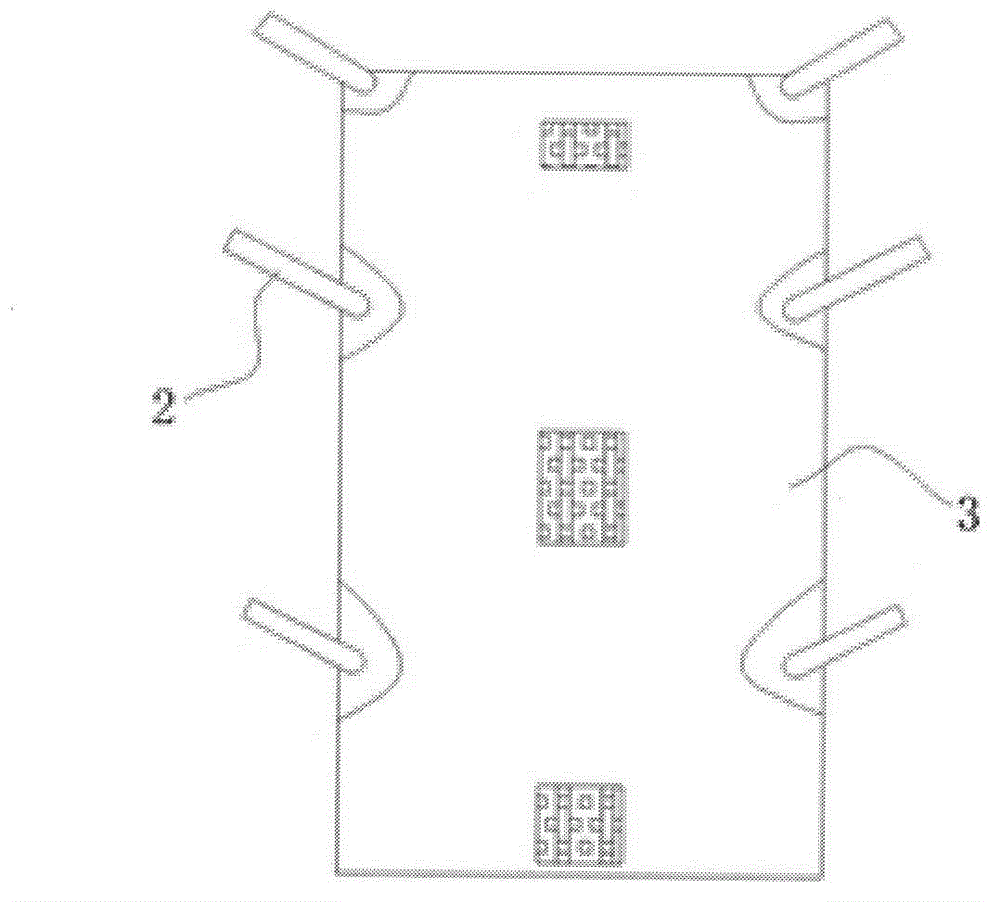

[0037] Such as Image 6 , Figure 7 , Figure 8 with Figure 9 As mentioned above, the thin-walled investment casting casting method provided by this embodiment includes the following steps:

[0038] a. First, prepare multiple hard plastic wires with a diameter of 1mm and a length of 100mm. The bending strength of the above-mentioned hard plastic wires is greater than 15Mpa, and the gasification temperature of burning loss is lower than 800°C;

[0039] b. Then glue one end of the hard plastic line in the previous step to the wax mold group 3 after the tree has been assembled, and the bonding length is 6mm;

[0040] c. Then dip the hard plastic wire in the previous step with the wax mold set 3 and paint the coating slurry and hang sand;

[0041] d. After the mold shell 4 is formed on the surface of the wax mold group 3, dewaxing and roasting are carried out, and the hard plastic line is burned to form a cavity 5 on the mold shell 4;

[0042] e. When pouring the molten stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com