Preparation method of xylitol and maltitol eutectic

A technology of maltitol and crystallized maltitol, which is applied in the field of preparation of xylitol and maltitol co-crystals, can solve problems such as difficult large-scale production, difficulty in crushing, and large power consumption, and achieve good economic benefits and social significance. Machinability, effect of expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 prepares xylitol and maltitol co-crystal

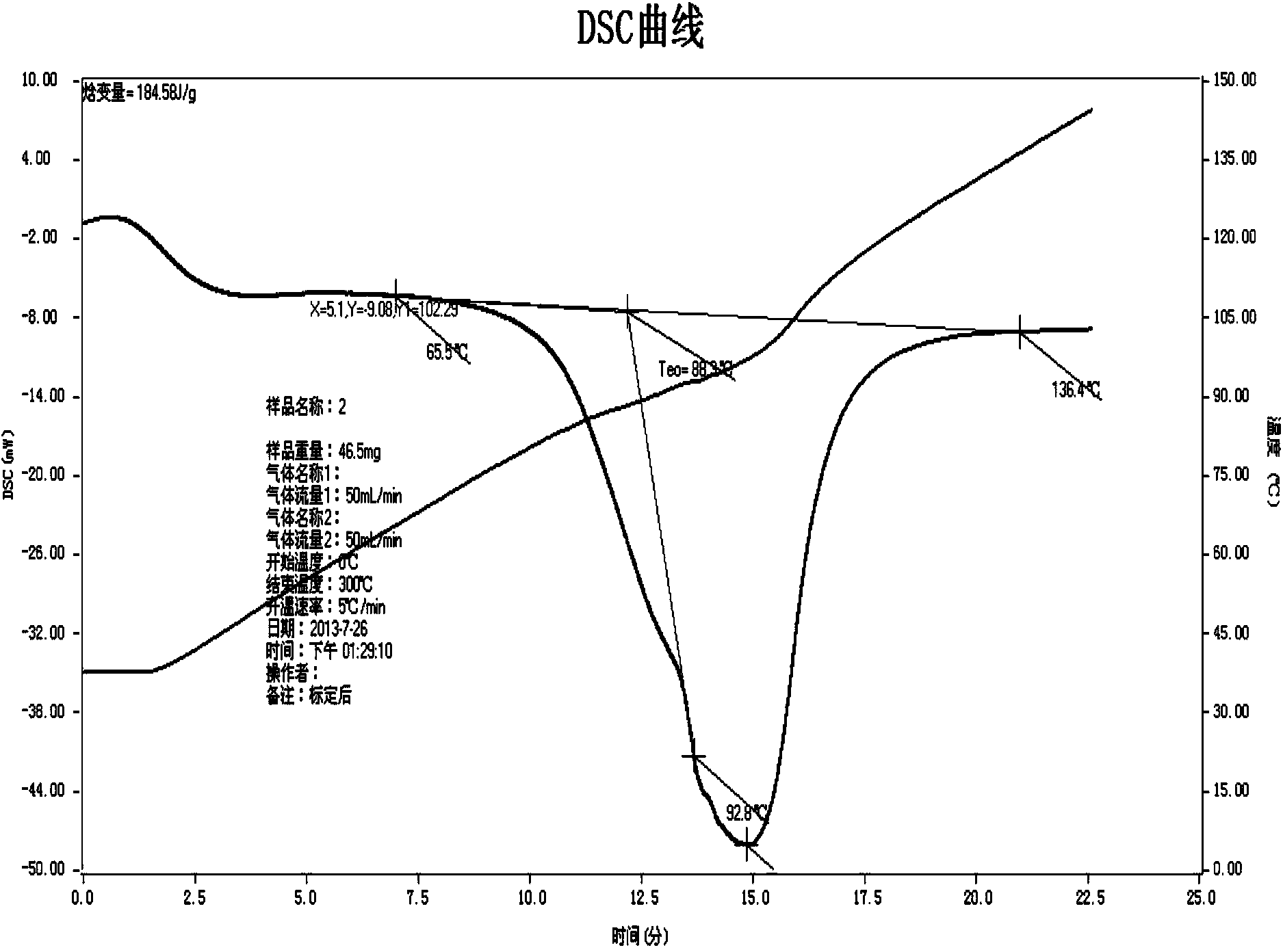

[0021] Mix crystalline xylitol and crystalline maltitol at a mass ratio of 10:1, then heat to a molten state with a solid mass fraction of 99.5%, drop the temperature to 120°C and add it to the seed crystal, which is crystalline xylitol and A mixture of crystallized maltitol, the ratio of xylitol and maltitol in the mixture is the same as that in the molten state, the amount of seed crystals used is 1 / 2 of the mass of the molten state, stirring while adding, so that the two are mixed evenly, and then passed The temperature is 25°C, the humidity is 35% of dry cold air for drying and cooling, the cooling rate is 15°C / h, and after cooling to 40°C, it is pulverized to obtain xylitol and maltitol co-crystals, which are displayed in differential scanning calorimetry. A single melting peak (eg figure 1 shown).

Embodiment 2

[0022] Embodiment 2 prepares xylitol and maltitol co-crystal

[0023] Mix crystalline xylitol and crystalline maltitol at a mass ratio of 2:1, then heat to a molten state with a solid mass fraction of 99.0%, drop the temperature to 160°C and add it to the seed crystal, which is crystalline xylitol and A mixture of crystalline maltitol. The ratio of xylitol and maltitol in the mixture is the same as that in the molten state. The amount of seed crystals used is twice the mass of the molten state. Stir while adding to make the two mix evenly, and then pass into the temperature 20°C, dry cold air with a humidity of 30% for dry cooling, the cooling rate is 5°C / h, cooled to 30°C and then pulverized to obtain xylitol and maltitol co-crystals.

Embodiment 3

[0024] Embodiment 3 prepares xylitol and maltitol co-crystal

[0025] Mix crystalline xylitol and crystalline maltitol at a mass ratio of 5:1, then heat to a molten state with a solid mass fraction of 99.2%, cool down to 150°C and add to the seed crystals, which are xylitol and maltose Alcohol co-crystal, the proportion of xylitol and maltitol in the co-crystal is the same as that in the molten state, the amount of seed crystal used is the same as that in the molten state, stir while adding, so that the two are evenly mixed, and then the temperature of feeding is 22°C , the dry cold air with a humidity of 32% was dried and cooled at a cooling rate of 10°C / h, cooled to 35°C and crushed to obtain xylitol and maltitol co-crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com