A planetary transmission assembly with clearance and damping adjustment functions

A technology of damping adjustment and planetary transmission, which is applied to transmission parts, transmissions, gear transmissions, etc., can solve the problems of unstable damping and many assembly steps, reduce manufacturing costs and turnover costs, simplify mechanisms, and facilitate assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

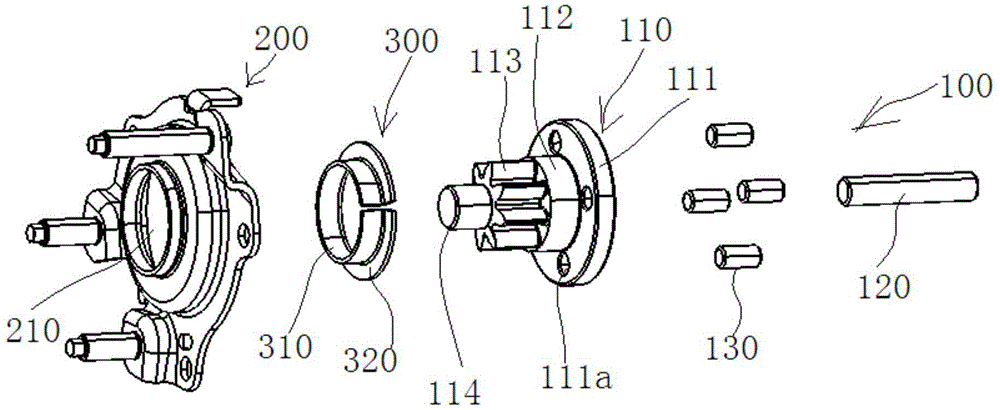

[0039] see Figure 3 to Figure 12 , a planetary transmission assembly with clearance and damping adjustment functions is shown in the figure, including three modularly designed and manufactured parts of the output gear member 10, the plastic bushing 20, and the planetary gear transmission member 30. The whole planetary transmission assembly adopts the support frame 40 (the function is the same as the reduction box shell in the prior art).

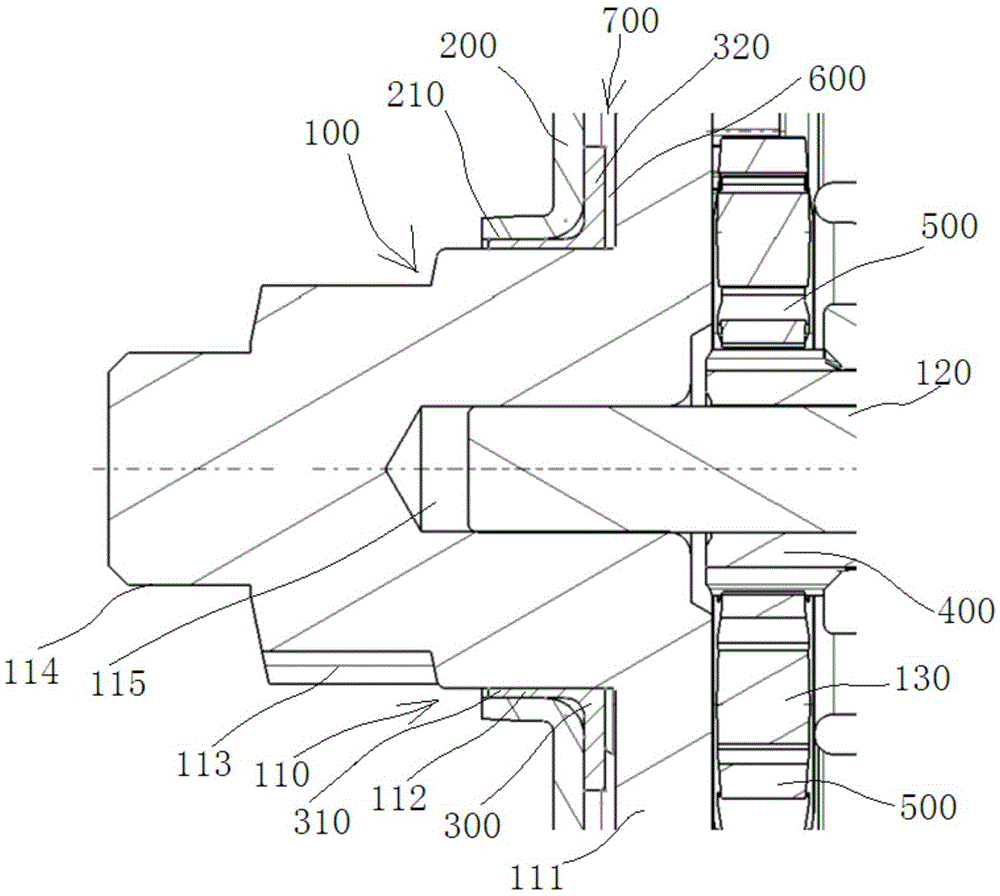

[0040] See especially Figure 5 and see also Figure 3 to Figure 12In other drawings, the output gear part 10 is made of metal material, which includes an outer support shaft section 11 coaxially arranged, an output gear section 12, an inner support shaft section 13, a planetary gear transmission member installation shaft section 14 and a sun gear installation The shaft section 15, the outer support shaft section 11 and the sun gear installation shaft section 15 are located at the inner and outer ends of the entire output gear part 10, th...

Embodiment 2

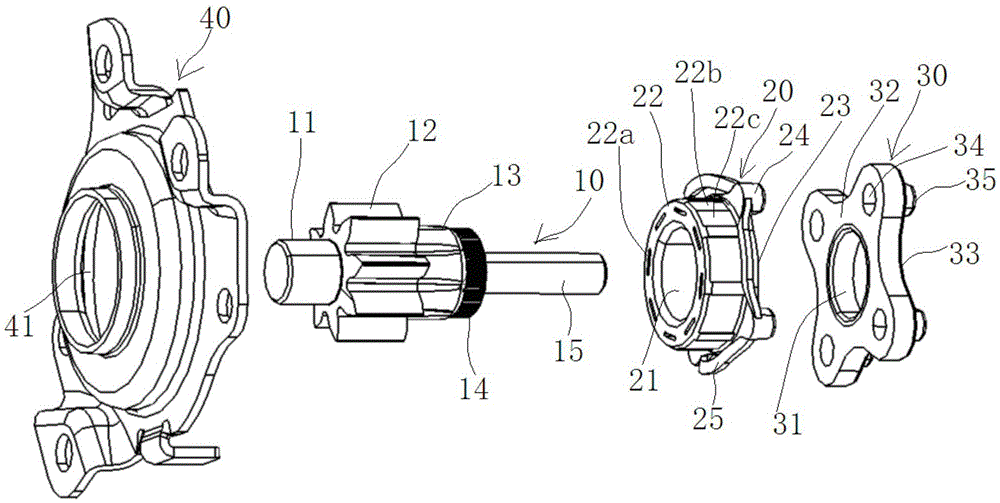

[0051] see Figure 13 to Figure 16 The difference between the planetary transmission assembly with clearance and damping adjustment functions provided in this embodiment and the first embodiment is that the planetary gear transmission parts are different, and the structures of the output gear part 10, the plastic bushing 20 and the support frame 40 are the same. see Figure 13 to Figure 16 , its planetary gear transmission part 30a is also a mold part, that is, it is manufactured by a mold, so that the overall strength is high and the manufacturing cost is low. The planetary gear transmission part 30a is basically a plate-shaped part, which has a central support hole 31a that is interference fit with the inner support section 14 on the output gear part, and the planetary gear transmission part 30a The outer end surface 32a of the inner end surface 33a is uniformly formed with four radial and circumferential positioning blind holes 34a of the planetary gear transmission parts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com