Technique for anti-seismic and energy-saving wall with built-in core net

A kind of core mesh and technology, applied in the direction of wall, shockproof, building components, etc., can solve the problem of cracks, hollow bulges, poor impact resistance of masonry infill walls, and poor shear resistance and seismic resistance at the interface between the thermal insulation layer and the base wall. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

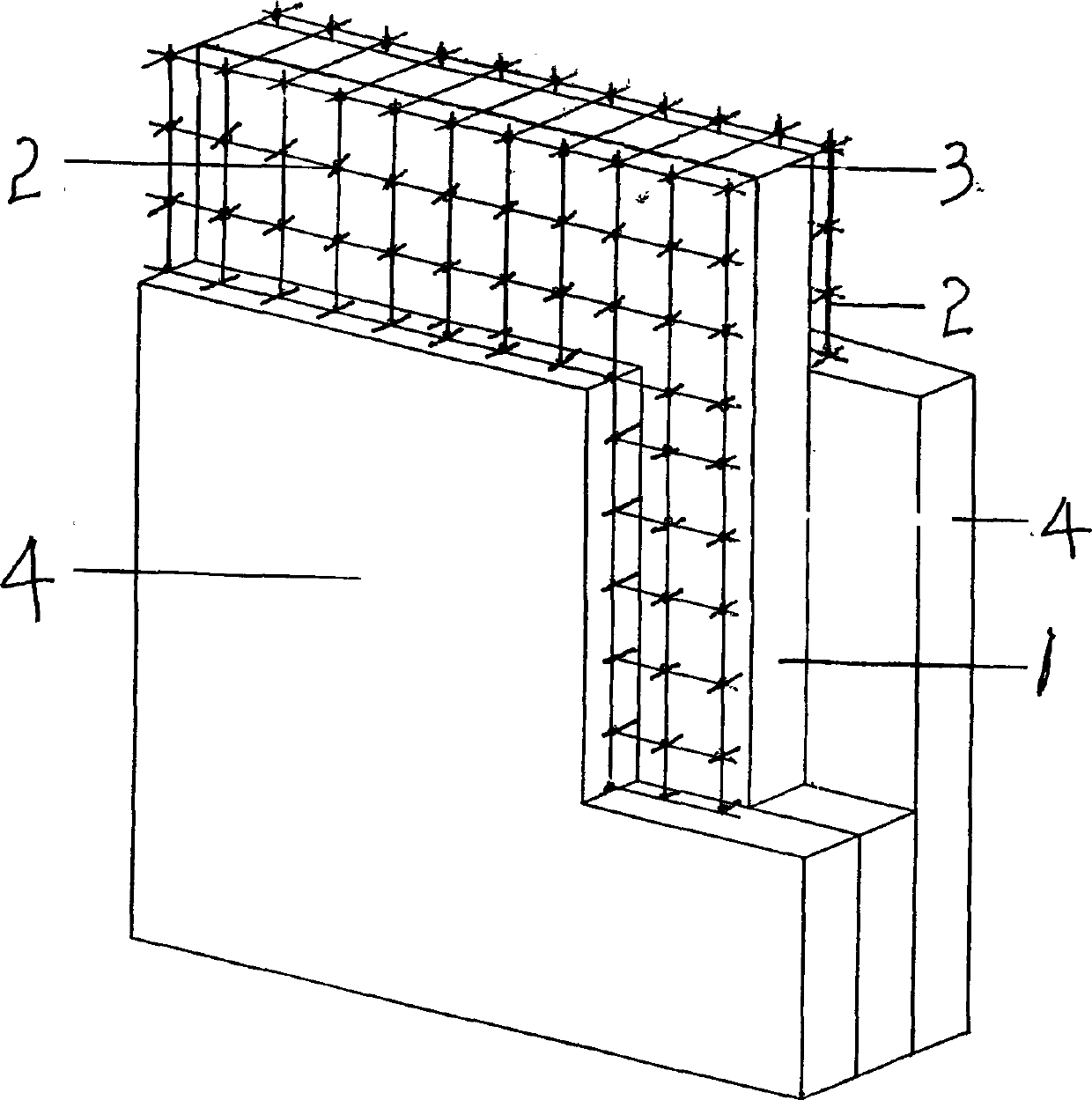

[0017] Figure 1 is the butt joint and assembly of sandwich panels. The specific method is: fix the sandwich panel upright at 0-30 mm from the outer edge of the side of the frame column, and assemble the panels with dovetail grooves and dovetail tenons to form the built-in sandwich panel 1 of the wall.

[0018] Figure 2 is the metal mesh hanging on both sides of the sandwich panel. The specific method is: the metal mesh on the inside of the sandwich panel is hung 30mm away from the sandwich panel, the mesh edge is connected to the embedded part of the frame, and the mesh edge is connected to the mesh edge; The embedded parts are connected, and the mesh edge is connected with the adjacent metal mesh, that is, the metal mesh 2 is formed on both sides of the sandwich panel.

[0019] Figure 3 is the metal mesh connection on both sides of the sandwich panel. The specific method is: use the metal tie bars 3 to penetrate the sandwich panel 1 to connect the metal mesh 2 on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com