Steel wire rope stranding equipment with heating device

A heating device and wire rope technology, which is applied to auxiliary devices for rope making, textiles, papermaking, textile cables, etc., can solve the problems of restricting the production specifications of plastic-coated wire ropes, unable to control the softening effect of plastics, affecting the lubrication effect of wire ropes, etc. EDM phenomenon, good adhesion effect, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

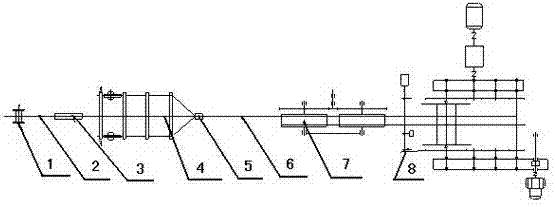

[0017] Above in conjunction with accompanying drawing, a kind of steel wire rope twisting equipment with heating device of the present invention is described in further detail:

[0018] figure 1 Among them, it consists of a core-releasing device 1, a heating device 3, a twisting rope basket 4, a rope closing device 5, a traction device 7 and a wire take-up device 8 arranged in sequence.

[0019] The heating device 3 of the present invention is arranged between the core-releasing device 1 and the twisted rope basket column 4. After the core-releasing device 1 releases the plastic-coated rope core 2, it enters the heating device 3 for heating, softens the plastic-coated rope core 2, and is contained in the plastic-coated rope core 2. The outer strands of the steel wire rope of the twisting rope basket hurdle 4 are closed at the rope closing device 5, and the steel wire rope 6 that is twisted enters the take-up device 8 to take-up after passing through the traction device 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com