Output-concentration-controllable adsorption system special for painting workshop

An adsorption system and concentration technology, applied in the field of adsorption systems, can solve the problems of reducing purification treatment efficiency, increasing purification treatment costs, and low VOCs concentration, and achieve the effects of preventing catalyst poisoning, reducing auxiliary heating, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

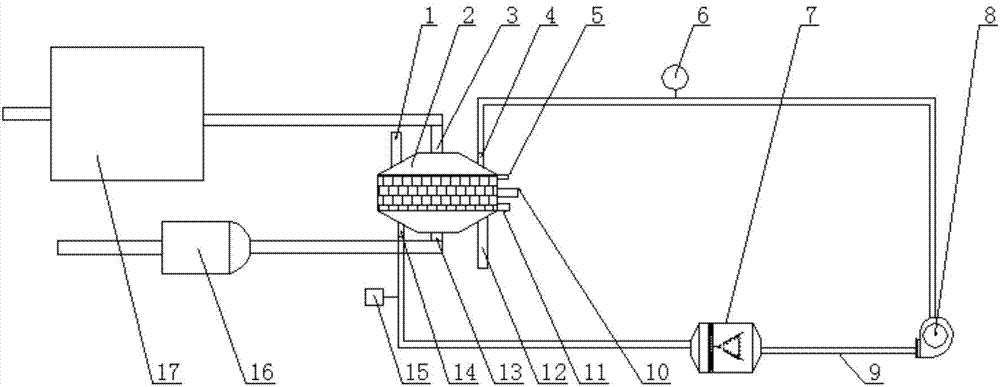

[0029] An adsorption system dedicated to the controllable output concentration of the spraying workshop, including a spray filter device 17 and an adsorption bed 2 with a controllable output concentration. The spray filter device includes a tower body 20, and a Air inlet 22, air outlet 25 is made on the upper part of the tower body opposite to the air inlet, and first filter layer 30, second filter layer 28 and defogging layer 26 are respectively arranged in the tower body from bottom to top, and the defogging layer is Mist eliminator, this demister forms triangular structure, is evenly distributed with bottom nozzle 33 below the first filter layer, is evenly distributed with middle nozzle 29 between the first filter layer and the second filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com