Energy-saving evaporating system without preheating or flash evaporation

An evaporation system, no preheating technology, used in multi-effect evaporation, aluminate/alumina/aluminum hydroxide purification, etc., can solve problems such as wasting energy, and achieve the goal of reducing construction investment, shortening evaporation process, and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

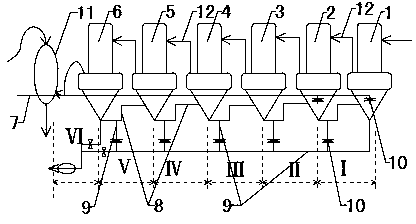

[0016] Refer to attached figure 1 : The energy-saving evaporation system without preheating and flashing of the present invention comprises a first-stage evaporator 1, a second-stage evaporator 2, a third-stage evaporator 3, a fourth-stage evaporator 4, a fifth-stage evaporator 5, and a sixth-stage evaporator 6. Stock solution pipeline 7, feed pipeline 8, evaporation masterbatch collection pipeline 9, valve 10, water cooler 11. The first-stage evaporator 1 is connected to the steam generation system, and the first-sixth-stage evaporators are connected in series with the steam pipeline 12, and the temperature in each evaporator is successively lowered step by step. The steam line 12 output from the six-stage evaporator 6 is connected to the water cooler 11 . Wherein the discharge port of the first-stage evaporator is connected to the feed port of its secondary evaporator through the material-passing pipeline 8, and the discharge port of the secondary evaporator is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com