Desalination technology in pickle production process

A production process and desalination technology, which is applied in the field of fermented food processing, can solve problems such as low desalination efficiency, achieve the effects of improving desalination efficiency, shortening desalination time, and saving desalination water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

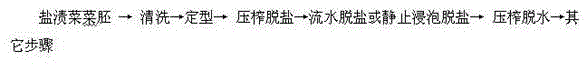

Method used

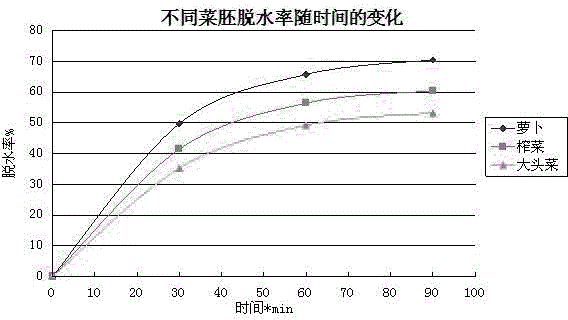

Image

Examples

Embodiment 1

[0028] 1. The tidied and cleaned salted fermented vegetable embryos are shaped and packed into bags, 30kg per bag; piled up, 8-10 bags per layer, 6-8 layers. After coding, press the weight plate onto the vegetable pile with a driving car, each weight is 500-1000kg, and build 3-5 layers, so that the weight ratio of the weight of the vegetable embryo after the weight is given to the shaped vegetable embryo is 2 -4:1, press for 15-60min. Cabbage germ loses 30%-85% of brine.

[0029] 2. Shake the pressed vegetable embryos and put them into the desalting machine or desalting tank, the feeding speed is 100kg / min, the desalination is 2-5%, and the rehydration and desalination time is 5-10min.

[0030] 3. During the process of running water desalination or static desalination, the desalination time is adjusted according to the salt content of raw vegetable germ.

[0031] 4. Dehydration

[0032] 5. Mixing materials and other follow-up.

[0033] The shaped pickle embryos are squeeze...

Embodiment 2

[0036] 1. The cleaned and cleaned salted fermented vegetable embryos are put into the pressing cylinder of the mechanical pressing equipment after being shaped, and each cylinder is 1-3 tons or more. Use mechanical pressing to give pressure to the vegetable embryos, so that the mechanical pressing equipment can give shape The weight ratio of the final vegetable germ to the finalized vegetable germ is 2-4:1, the pressing time is 15-60min, and the vegetable germ loses 35%-85% of salt water.

[0037] 2. Use mechanical vibration to loosen the vegetable embryo, put it into the desalter or tank conveyor belt at a certain feeding speed (generally 100kg / min), enter the desalter or tank, desalinate to 2%-5%, rehydrate and desalinate The time is generally 5-10 minutes.

[0038] 3. During the desalination process, adjust the desalination time according to the salt content of the raw vegetable germ.

[0039] 4. Dehydration

Embodiment 3

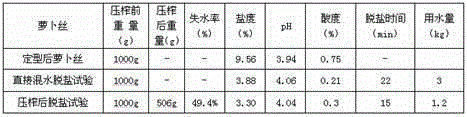

[0041] Weigh 1000g of shredded radish from the workshop and measure the salinity, acidity and pH of the dish; then squeeze 3000 g of the dish for 50 minutes, weigh the weight of shredded radish after pressing and calculate the water loss rate of shredded radish, then desalinate and rehydrate the dish. Water 1:3; Stir fully to desalinate to about 2-5%, record the rehydration and desalination time and test the salinity, acidity and pH of the dishes.

[0042] Control group: weigh 1000g shredded radish, test the salinity, acidity and pH of the dishes; desalinate and rehydrate, fully stir the vegetable water at 1:3 to desalinate to 2-5%, record the desalination time and test the salinity, acidity and pH of the dishes.

[0043] Water loss rate = (weight of food before pressing - weight of food after pressing) / weight of food before pressing × 100%

[0044] Table 1

[0045]

[0046] The finalized salt base is squeezed to remove 49.4% of the high-salinity water, saving 60% of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com