Method for easily stripping optical fibers or optical fiber ribbons in optical fiber bundles and silicone oil coating device

An optical fiber bundle and easy stripping technology, which is applied in the direction of bundled optical fibers, etc., can solve the problems of difficult gasification and difficulty in uniform adhesion of silicone oil, and achieve the effect of easy stripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example is manufactured as Figure 7 The cross-section shown is for a circular fiber bundle.

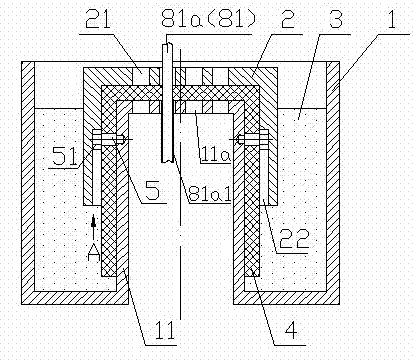

[0044] Put water-based silicone oil in oil tank 1. The viscosity of the silicone oil is 350-600mpa.s at 25°C, and the density is 1.01-1.03 g / cm2. Its physical properties are good enough to meet the formation of a thin silicone oil layer for optical fibers .

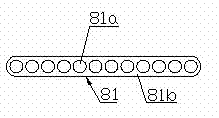

[0045] 36 optical fibers 81a are respectively passed through a hole 21 on the cover plate 2 (see Figure 6 ) into the medium-density antistatic sponge 4, and pass through the sponge 4 through the hole 11a on the protrusion 11. When the optical fiber 81a passes through the sponge 4, it absorbs water-based silicone oil and coats the outer surface of the sponge with a uniform thickness of 10-30nm. The silicone oil layer 81a1.

[0046] 36 optical fibers attached with a water-based silicone oil layer pass through a belt mold equipped with resin at a speed of 100 m / s, and form an uncured optical fiber bundle under t...

Embodiment 2

[0049] This example is manufactured as Figure 8 Shown is a bundle of optical fibers formed in a ribbon stacked arrangement.

[0050] Put water-based silicone oil in the oil tank 1. The viscosity of the silicone oil is 295-500mpa.s at 25 °C, and the density is 1.01-1.03 g / cm. Formation.

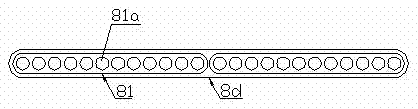

[0051] Pass 6 optical fibers together with 81 through the holes 21 on the cover plate 2 at a speed of 200 m / s (see Figure 9 ) into the medium-density antistatic sponge 4, and pass through the sponge 4 through the hole 11a on the protrusion 11, and when the optical fiber ribbon 81 passes through the sponge 4, the sponge that absorbs water-based silicone oil will align the outer surface of the optical fiber ribbon 81 Apply a silicone oil layer 81a1 with a uniform thickness of 10-30nm.

[0052] A number of fiber bundles 81 attached with water-based silicone oil layers pass through a bundle mold equipped with resin to form uncured fiber bundles under the action of resin bonding; the uncur...

Embodiment 3

[0055] This example is manufactured as Figure 10 The shown bundles are similar to stacked fiber optic bundles formed by arrayed distribution fibers.

[0056] Put water-based silicone oil in the oil tank 1. The viscosity of the silicone oil is 295-400mpa.s at 25°C, and the density is 1.01-1.02 g / cm. Its physical properties are good enough to meet the formation of a thin silicone oil layer for optical fibers. .

[0057] The 72 optical fibers 81a pass through the holes 21 arranged in an array on the cover plate 2 at a speed of 500 m / s respectively (see Figure 11 ) and poke into the low-density antistatic sponge 4, and pass through the hole 11a on the protrusion 11 from the sponge 4, and when the optical fiber 81a passes through the sponge 4, the sponge absorbing water-based silicone oil coats the outer surface of the optical fiber 81a for 10 A silicone oil layer 81a1 with a uniform thickness of ~30nm.

[0058] A number of optical fibers 81a attached with a water-based si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com