A Realization Method of Flow-through Steam Generator

A technology of a steam generator and a realization method, which is applied in the directions of steam generation method, steam generation, lighting and heating equipment, etc., can solve the problems of high-pressure steam leakage and waste of energy, and achieve the effect of avoiding waste and realizing precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

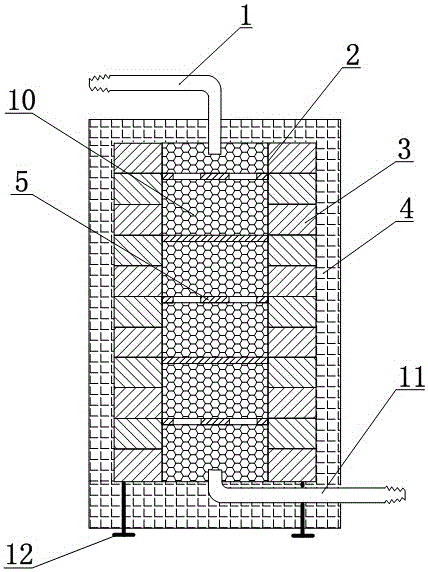

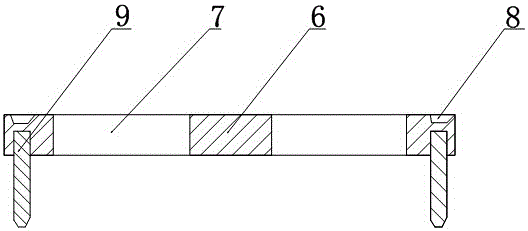

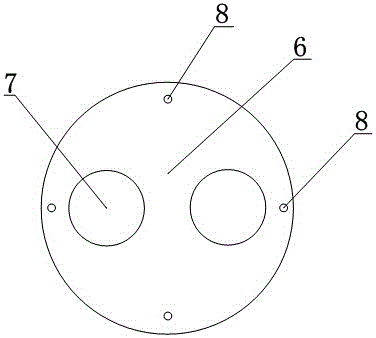

[0030] Such as figure 1 As shown, the present invention provides a heating device for real-time online steam generation, which includes a water inlet pipe 1 , a vaporizer 2 , an electric temperature control device 3 and a steam discharge pipe 11 . One end of the water inlet pipe 1 penetrates into the interior through the top of the vaporizer 2, and one end of the steam discharge pipe 11 penetrates into the interior through the bottom of the vaporizer 2. In this embodiment, the vaporizer is a stainless steel cylindrical cylinder, and the water inlet pipe 1 penetrates One end of the vaporizer 2 is welded together with the top end cap of the vaporizer, and the end port is about 5 mm higher than the plane of the end cap; the end of the steam discharge pipe 11 penetrating into the vaporizer 2 is also welded with the bottom end cap of the vaporizer, and the The end ports are flush with the top surface of the bottom end cap. The water inlet pipe 1 is used to inject liquid water, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com