Soldering tin capable of not dissolving copper

A solder, parts by weight technology, used in welding media, welding equipment, welding/welding/cutting items, etc., which can solve problems such as at least 380 degrees Celsius and prolonged welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

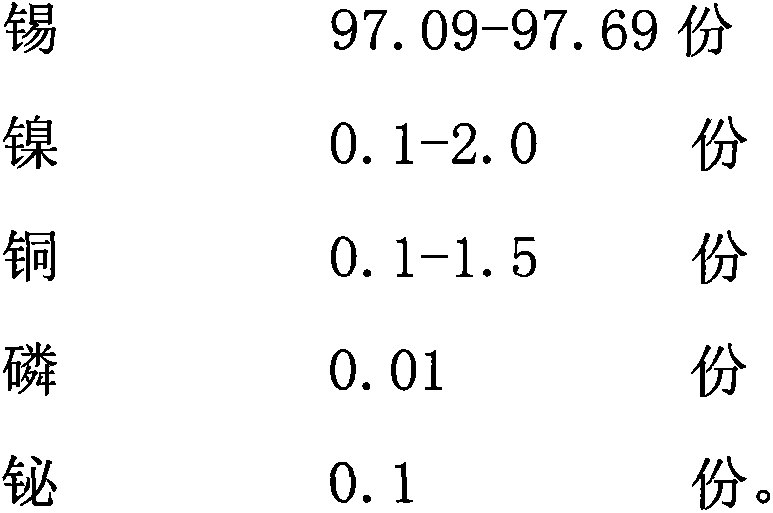

[0012] A copper-insoluble solder comprising the following components in parts by weight:

[0013]

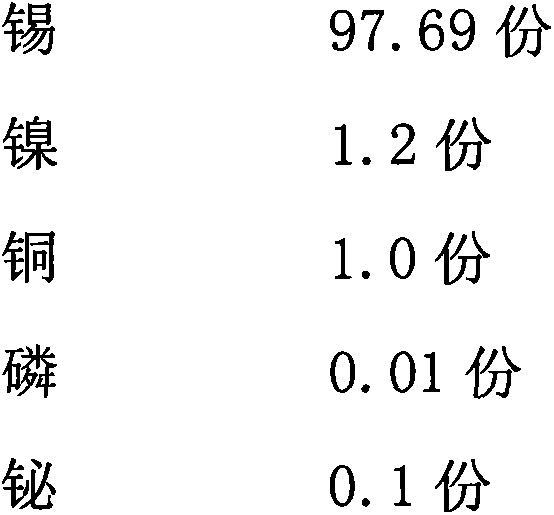

[0014] Among them, the purity of tin is 99.99%.

Embodiment 2

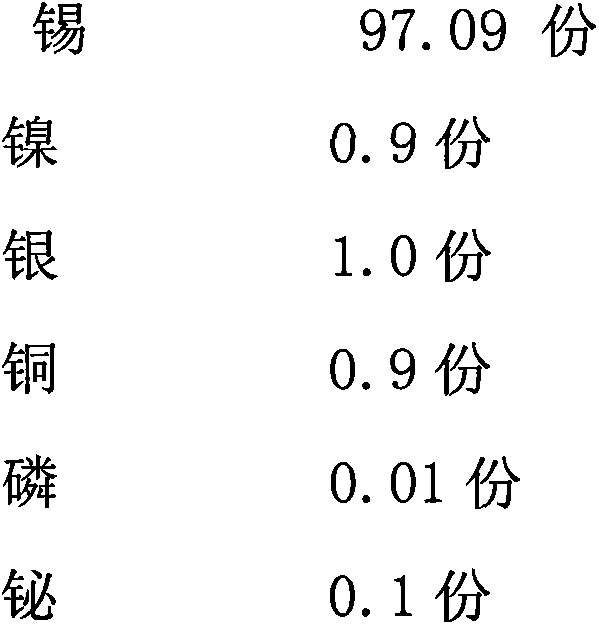

[0016] A copper-insoluble solder comprising the following components in parts by weight:

[0017]

[0018] Among them, the purity of tin is 99.99%.

[0019] This solder saves cost. It has been verified that 90 enameled wires with different diameters are welded with the above-mentioned solder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com