System and method for evaporating liquefied natural gas by utilizing intermediate medium

A technology of liquefied natural gas and natural gas, which is applied to container discharge methods, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large circulation resistance, high investment, and large volume of intermediate media, and achieve reduced circulation resistance and energy saving The effect of low tube sheet cost and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

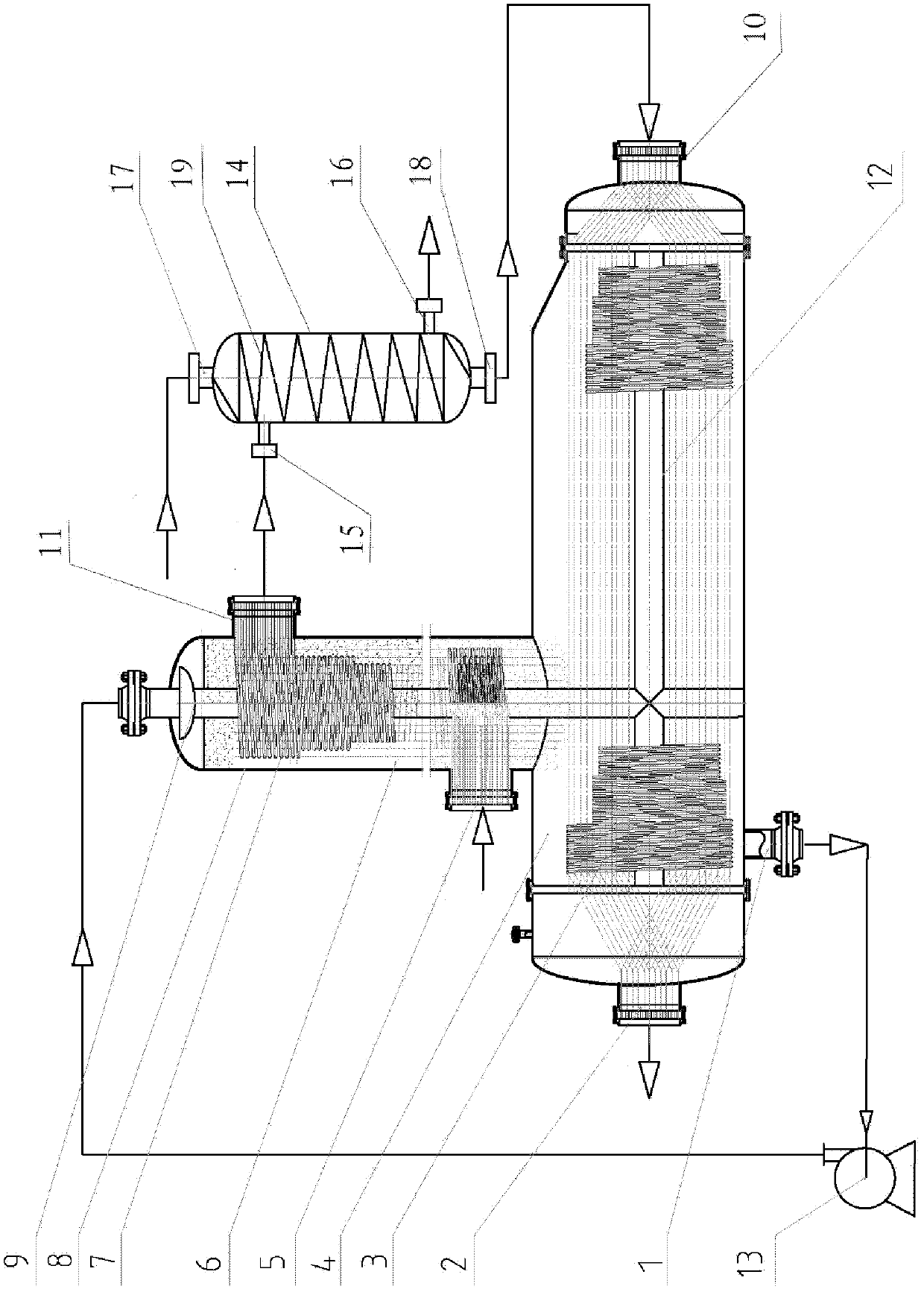

[0037] like figure 1 As shown, the system for vaporizing liquefied natural gas using an intermediate medium provided by the present invention includes: a first medium outlet 1, a second medium outlet 2, a second pipeline 3, a lower cavity 4, an LNG inlet 5, and an upper cavity 6 , LNG pipeline 7, first heat exchanger 8, first medium inlet 9, second medium inlet 10, LNG outlet 11, internal support pipe 12, circulation pump 13, second heat exchanger 14, natural gas outlet 15 , natural gas outlet 16, heat medium inlet 17 and heat medium outlet 18.

[0038] Wherein, the lower cavity 4 and the upper cavity 6 are connected to each other by welding two cylindrical cavities. The central axis of the lower cavity 4 is horizontal, and the central axis of the upper cavity 6 is vertical.

[0039] The upper cavity 6 is provided with a first medium inlet 9 , and the lower cavity 4 is provided with a first medium outlet 1 . Specifically, the first medium inlet 9 is located at the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com