Method for preventing liquid accumulation of compressor and air conditioner

A technology for compressors and air conditioners, which is applied to refrigerators, heating methods, mechanical equipment, etc., and can solve problems such as large thermal resistance, low efficiency, and reduced service life of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] The air conditioning unit operates in a low-temperature environment. Due to poor heat exchange, it is easy for the refrigerant to evaporate incompletely, causing the low-temperature liquid refrigerant to return to the gas-liquid separator and compressor, which affects the reliability of the whole machine.

[0040] This embodiment provides a method for preventing liquid accumulation in a compressor, which specifically includes the following steps.

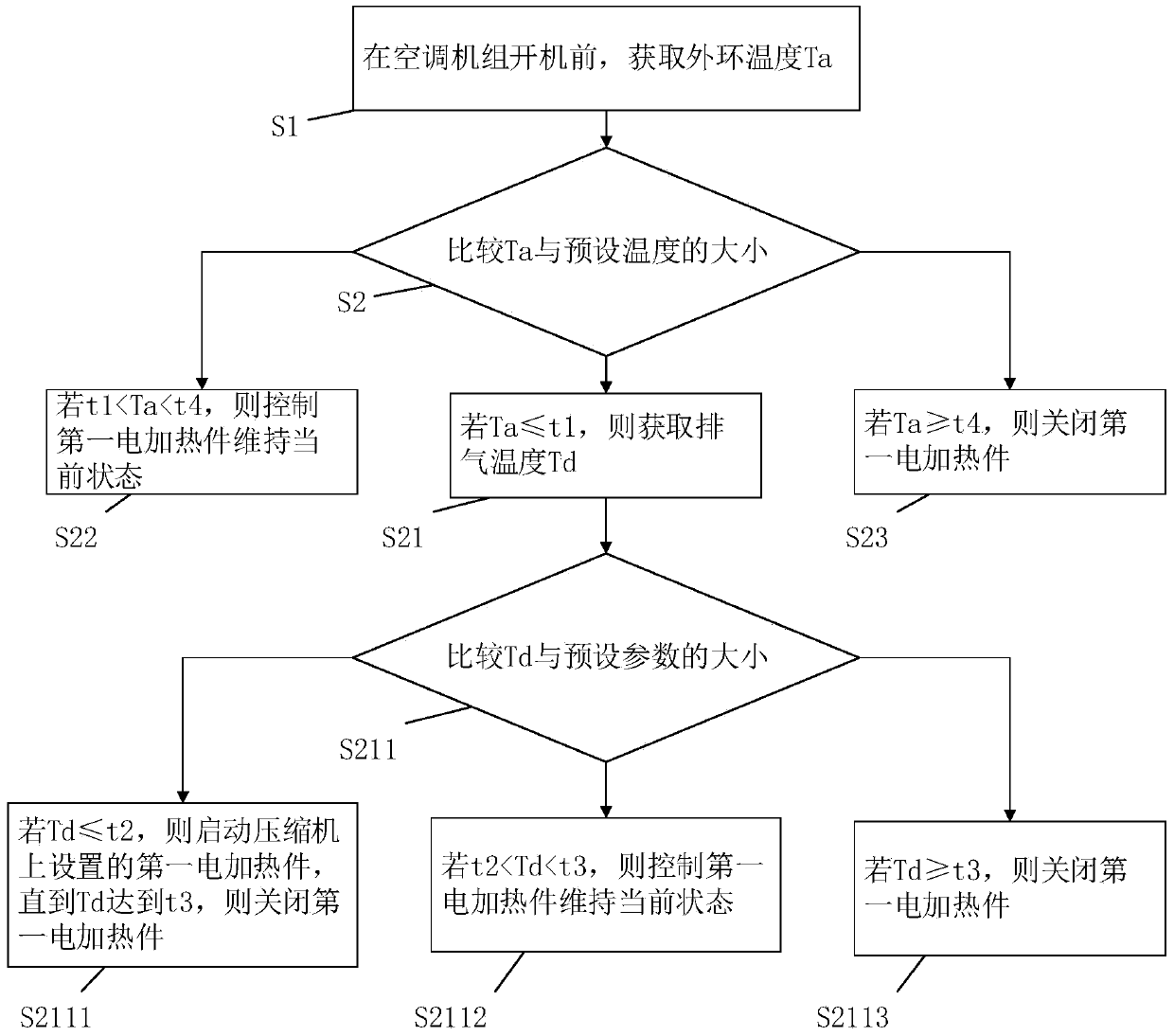

[0041] S1, see figure 1 , to obtain the outer ring temperature Ta before the air-conditioning unit is turned on.

[0042] Among them, the outer ring temperature Ta refers to the external ambient temperature of the air conditioning unit.

[0043] S2, comparing the outer ring temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com