Measuring method of light intensity distribution

A technology of light intensity distribution and measurement method, applied in the direction of completely visual method, can solve the problems of low sensitivity of thermal sensor, narrow light wave band, slow response speed, etc., and achieve high sensitivity, high absorption rate and high resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

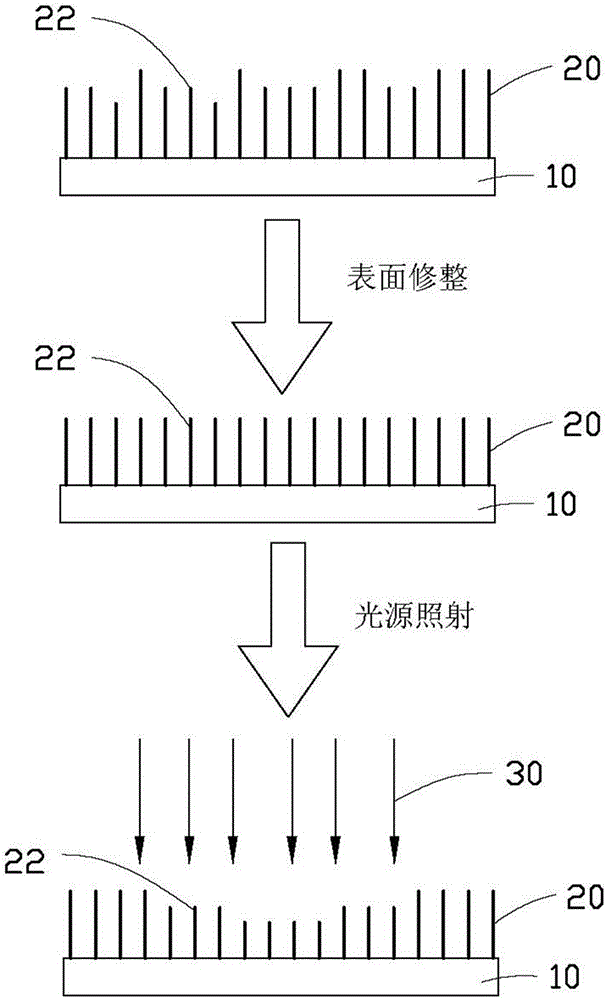

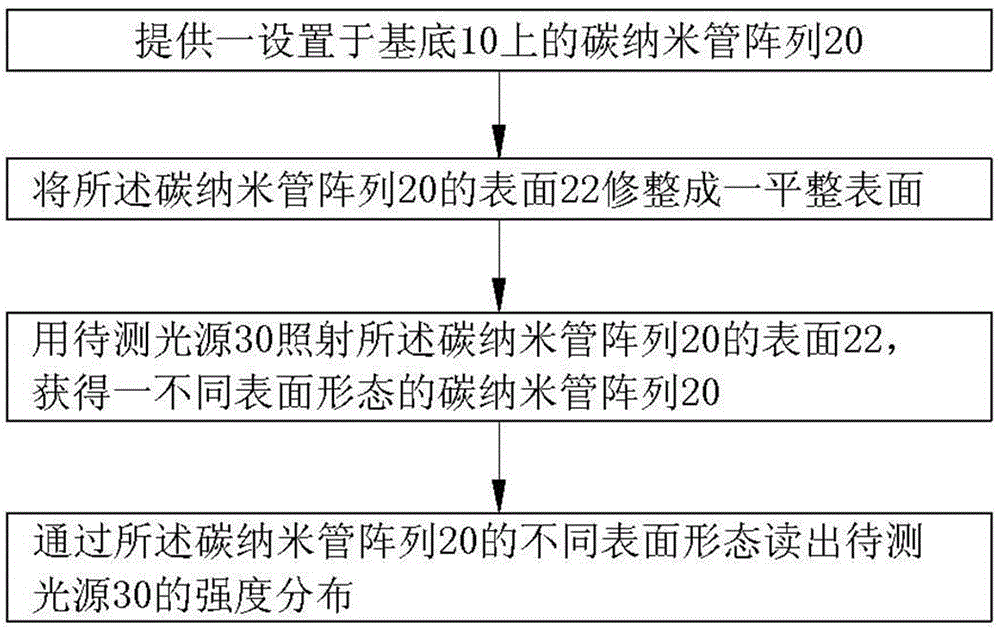

[0020] Please also refer to figure 1 and figure 2 , the first embodiment of the present invention provides a method for measuring light intensity distribution, the method includes the following steps:

[0021] S1: providing a carbon nanotube array 20, the carbon nanotube array 20 is disposed on a substrate 10, the carbon nanotube array 20 has a first surface 22;

[0022] S2: trimming the first surface 22 of the carbon nanotube array 20 into a flat surface;

[0023] S3: irradiating the first surface 22 treated in step S2 with the light source 30 to be tested, to obtain a carbon nanotube array 20 with different surface morphology; and

[0024] S4: Read out the intensity distribution of the light source 30 to be measured according to the different surface morphology of the carbon nanotube array 20 .

[0025] In step S1, the substrate 10 is an insulating substrate. The material of the substrate 10 can be silicon, silicon dioxide, silicon carbide, quartz, or glass. The thickn...

Embodiment 2

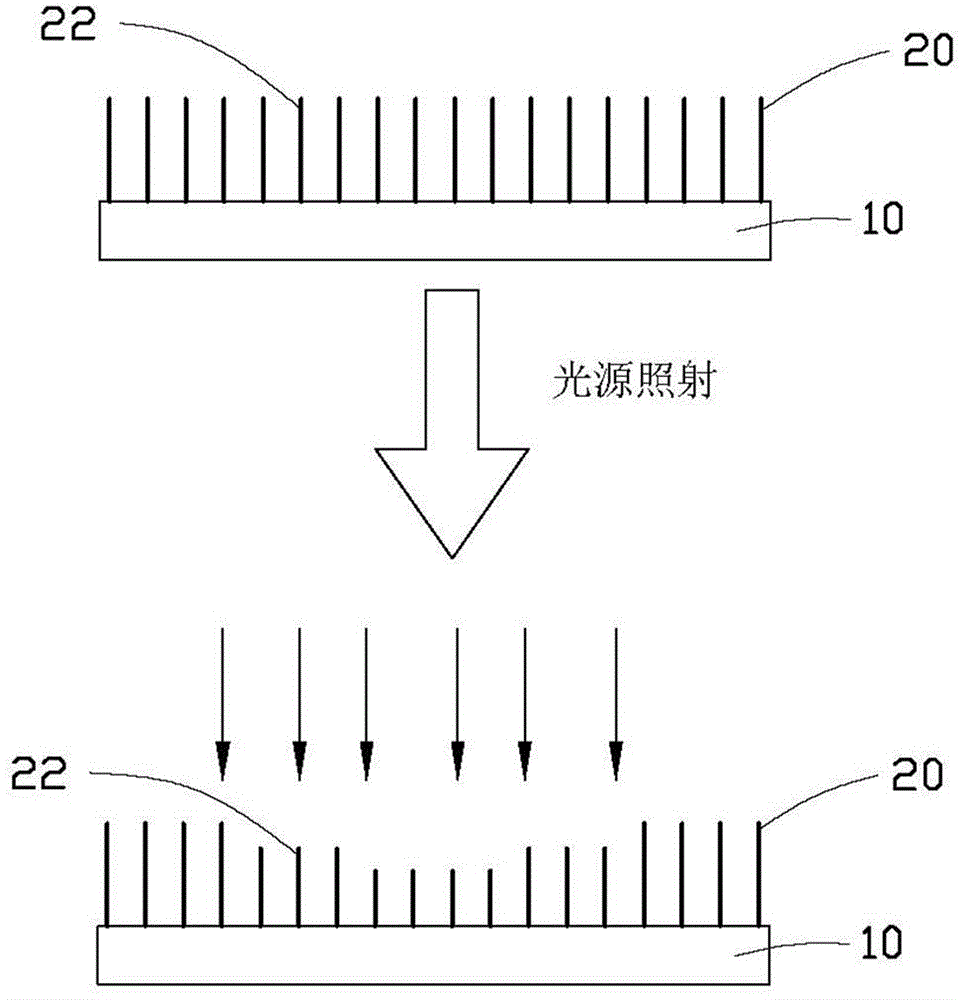

[0041] Please also refer to image 3 and Figure 4 , the second embodiment of the present invention provides a method for measuring light intensity distribution, the method includes the following steps:

[0042] S1: Provide a super-parallel carbon nanotube array 20, the super-parallel carbon nanotube array 20 is disposed on a substrate 10, the super-parallel carbon nanotube array 20 has a flat first surface 22;

[0043] S2: Irradiating the first surface 22 of the super-aligned carbon nanotube array 20 with the light source 30 to be measured to obtain a super-aligned carbon nanotube array 20 with different surface morphology; and

[0044] S3: Read out the intensity distribution of the light source 30 to be measured according to the different surface morphology of the superparallel carbon nanotube array 20 .

[0045] In step S1, the preparation method of the super-aligned carbon nanotube array 20 includes the following steps: (a) providing a flat growth substrate, the growth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com