Rotation heat storage type waste gas incinerating device

An incineration device and regenerative technology, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of difficult installation and replacement of regenerators, waste of regenerator materials, and difficulty in processing regenerators. Cross-contamination occurs, maintenance is easy, and the effect of improving the average thermal decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

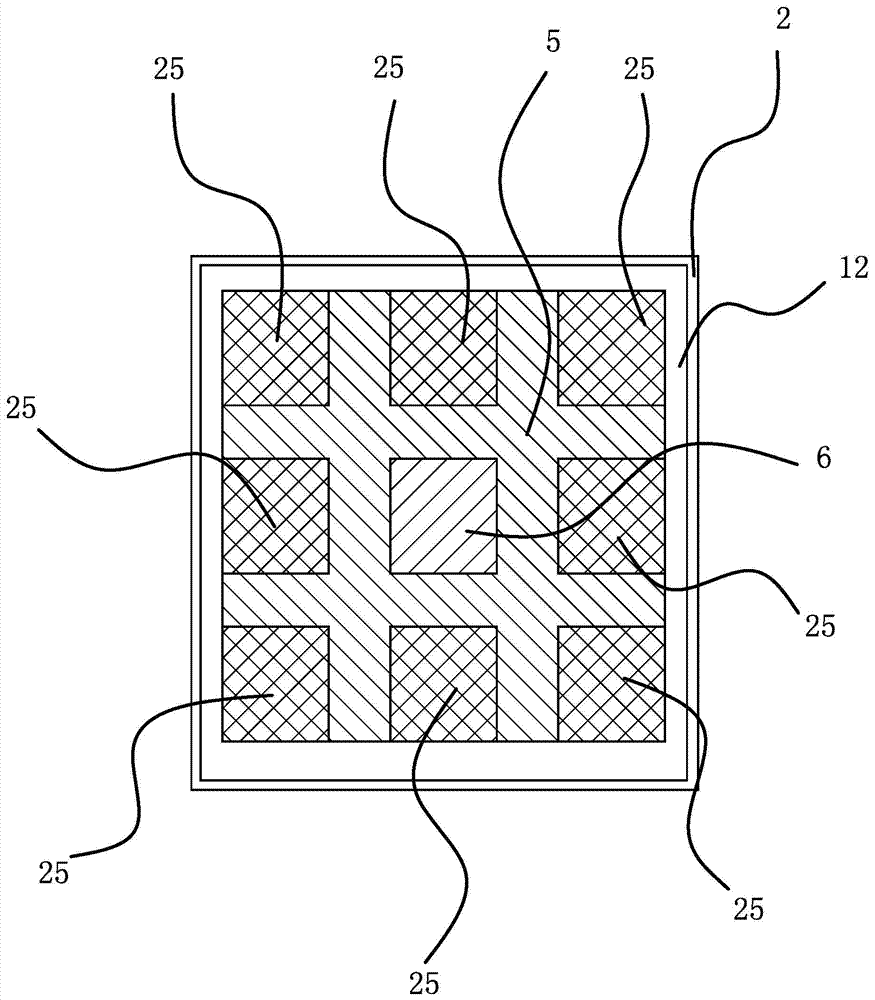

[0024] figure 1 , figure 2As shown, the rotary regenerative waste gas incinerator includes a rotary reversing valve 1 and an incinerator 2 with a square cavity. The rotary reversing valve 1 has an intake area 17, an exhaust area 20, a purge area 23 and a blind area 24. . The upper part of the cavity of the incinerator 2 is a combustion chamber 3, the upper part of the combustion chamber 3 is provided with a burner 4, and the lower part of the cavity is provided with a partition 5 that divides the cavity into nine square chambers 6 in the form of three columns and three columns. . The square chamber 6 located in the center is sealed, and the remaining eight square chambers 6 are provided with a regenerator 7 and a grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com