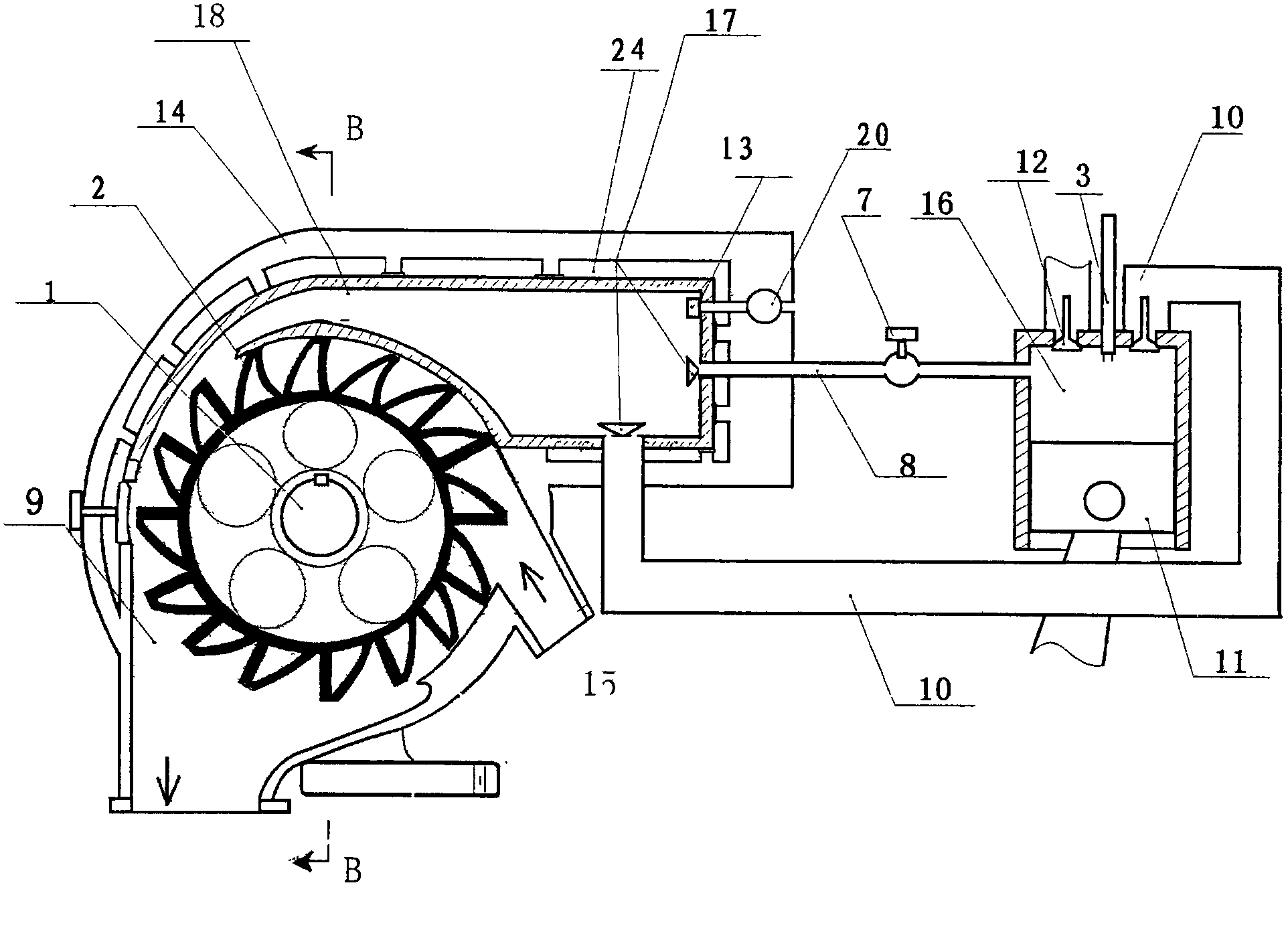

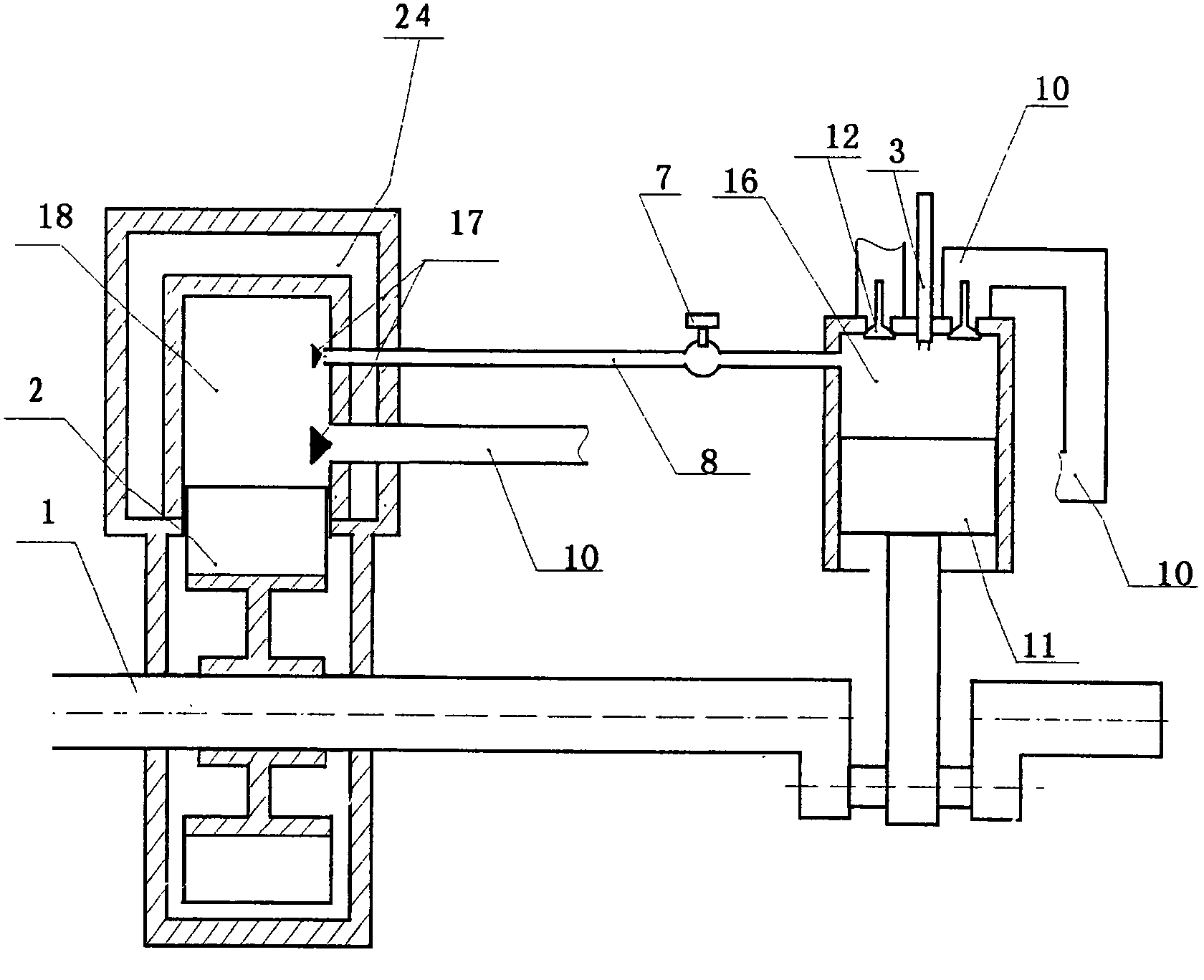

Double internal combustion super energy-saving engine

A super energy-saving, engine technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve problems such as power rise and acceleration rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] When the starter motor drives the main shaft to rotate, air entry, fuel injection, water injection, and spark plug ignition are carried out simultaneously. When the flame produced by the combustion cylinder (16) is sprayed into the depth of the steam cylinder (18) to add steam, when the combustion cylinder ( 16) When the high-temperature exhaust gas generated is sprayed into the deep inside of the steam cylinder (18) to add steam, the water will generate ultra-supercritical power steam with particularly strong directionality and huge impact force under the condition of instantaneous heating to push the blades on the turbine The turbine rotates to generate the maximum torque, and the turbine rotates to drive the main shaft (1) at its center to rotate and output power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com