Device and method of preparing electrostatic spinning polymer/inorganic particle nano-composite film

A nano-composite, inorganic particle technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of affecting fiber fineness and filamentation effect, inability to take advantage of the ultra-high specific surface area structure of nanoparticles, and uneven dispersion. Achieve the effects of flexible optional range, wide application range and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

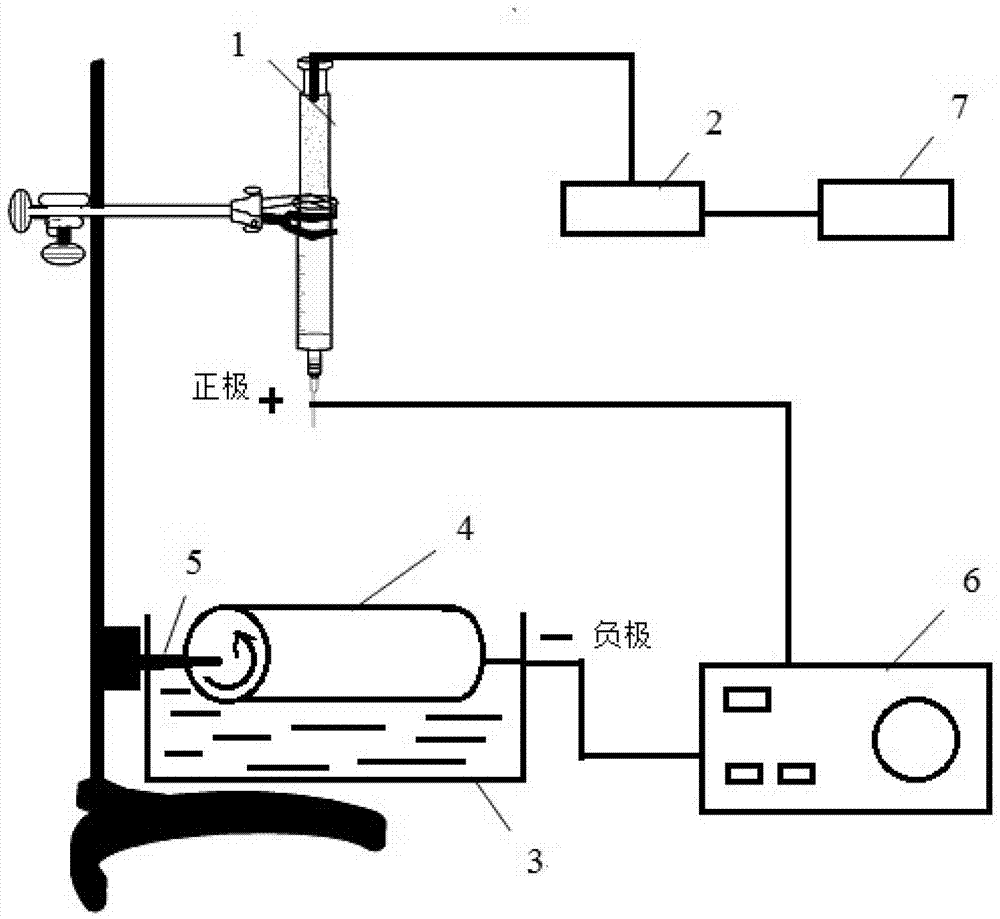

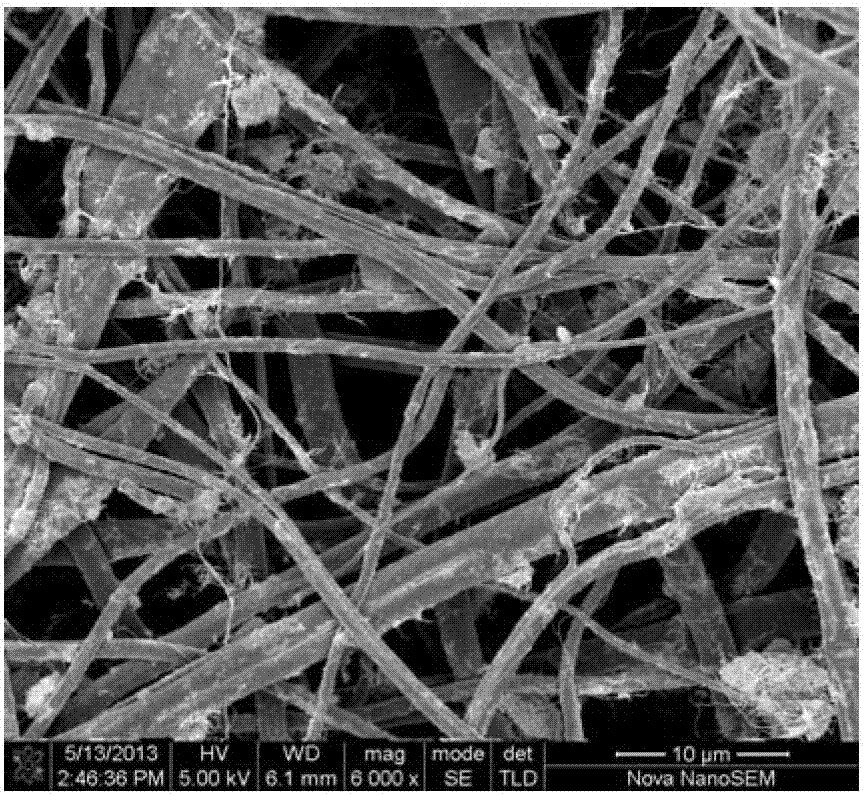

[0034] First, polymer spinning solution was prepared in polymer spinning solution storage tank 7, and 60ml of chloroform and 20ml of absolute ethanol were measured and mixed evenly, then 8g of polylactic acid was added, and magnetically stirred at 40°C for 2h. Then prepare an impregnation solution, weigh 0.05 g of carbon nanotubes, add 200 ml of absolute ethanol, and ultrasonically disperse for 20 minutes to make the dispersion even.

[0035] Inject the above-mentioned dipping liquid into the dipping tank 3 until the lower part of the receiving drum 4 is immersed in the above-mentioned dipping liquid, then start the motor 5 to make the receiving drum 4 rotate at a speed of 500r / min; connect the high-voltage power supply 6 and apply a voltage of 20kv , to form a high-voltage electrostatic field between the syringe 1 and the receiving drum 4;

[0036] Simultaneously open syringe pump 2, under the advance speed of 1ml / h, the polymer spinning liquid in the polymer spinning liquid ...

Embodiment 2

[0038]First, polymer spinning solution was prepared in polymer spinning solution storage tank 7, and 50 ml of dimethylacetamide was measured, then 5 g of polyvinylidene fluoride was added, and magnetically stirred at 60° C. for 2 hours. Then prepare an impregnation solution, weigh 0.1 g of graphene oxide, add 500 ml of distilled water, and ultrasonically disperse for 15 minutes to make the dispersion even.

[0039] Inject the above-mentioned dipping liquid into the dipping tank 3 until the lower part of the receiving drum 4 is immersed in the above-mentioned dipping liquid, then start the motor 5 to make the receiving drum 4 rotate at a speed of 100r / min; connect the high-voltage power supply 6 and apply a voltage of 20kv , to form a high-voltage electrostatic field between the syringe 1 and the receiving drum 4;

[0040] Simultaneously turn on the syringe pump 2, and provide the polymer spinning solution in the polymer spinning solution storage tank 7 to the inside of the syr...

Embodiment 3

[0042] First, polymer spinning solution was prepared in polymer spinning solution storage tank 7, and 60ml of chloroform and 20ml of absolute ethanol were measured and mixed evenly, then 8g of polylactic acid was added, and magnetically stirred at 40°C for 2h. Then prepare an impregnation solution, weigh 0.05g of graphene, add 500ml of absolute ethanol, and ultrasonically disperse for 30min to make it evenly dispersed.

[0043] Inject the above-mentioned dipping liquid into the dipping tank 3 until the lower part of the receiving drum 4 is immersed in the above-mentioned dipping liquid, then start the motor 5 to make the receiving drum 4 rotate at a speed of 800r / min; connect the high-voltage power supply 6 and apply a voltage of 20kv , to form a high-voltage electrostatic field between the syringe 1 and the receiving drum 4;

[0044] Simultaneously open the syringe pump 2, and provide the polymer spinning solution in the polymer spinning solution storage tank 7 to the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com