Lubricating grease composition for elevator wire ropes and preparation method thereof

A technology of grease composition and steel wire rope, which is applied in the field of grease, can solve problems such as not being able to meet protection requirements, and achieve the effects of low production cost, convenient coating, high adhesion and penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

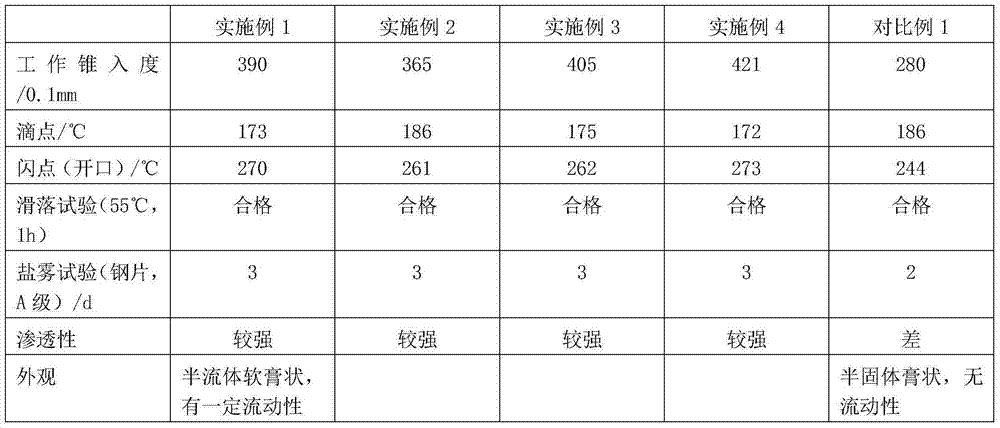

Examples

Embodiment 1

[0013] In terms of parts by weight, put 50 parts of base oil into the kettle, heat up to 130°C, add 5 parts of fatty acid calcium until it is completely melted, maintain the temperature of the material at about 130°C, and keep it for 20 minutes, then put in 10 parts of microcrystalline wax until it is completely dissolved. Keep it for 50 minutes, then add 2 parts of nano-silica, 1 part of oleic acid, 3 parts of alkyl diphenylamine, 1 part of barium petroleum sulfonate, and 2 parts of sodium metaborate to dissolve them all, and stir at this temperature for 55 minutes , the temperature is naturally lowered to below 90°C, and the kettle can be taken out to obtain the grease composition.

Embodiment 2

[0015] In terms of parts by weight, put 60 parts of base oil into the kettle, heat up to 130°C, put in 7 parts of fatty acid sodium until it is completely melted, maintain the temperature of the material at about 130°C, keep it for 25 minutes, and then put in 20 parts of microcrystalline wax until it is completely dissolved. Keep it for 50 minutes, then add 4 parts of nano-silica, 1 part of oleic acid, 4 parts of alkyl diphenylamine, 1 part of barium petroleum sulfonate, and 2 parts of potassium metaborate to dissolve them all, and stir at this temperature for 50 minutes , the temperature is naturally lowered to below 90°C, and the kettle can be taken out to obtain the grease composition.

Embodiment 3

[0017] In terms of parts by weight, put 70 parts of base oil into the kettle, heat up to 140°C, add 9 parts of fatty acid sodium until it is completely melted, maintain the temperature of the material at about 140°C, and keep it for 20 minutes, then put in 30 parts of microcrystalline wax until it is completely dissolved. Keep it for 50 minutes, then add 6 parts of nano-silica, 1 part of oleic acid, 6 parts of alkyl diphenylamine, 1 part of barium petroleum sulfonate, and 5 parts of potassium metaborate to dissolve them all, and stir at this temperature for 50 minutes , the temperature is naturally lowered to below 90°C, and the kettle can be taken out to obtain the grease composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com