A kind of water-based anti-corrosion decorative fluorocarbon paint and preparation method thereof

A fluorocarbon paint and anti-corrosion technology, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of high construction conditions and supporting materials, poor performance of decorative coatings, lack of elasticity, etc., and achieve a smooth and smooth appearance of the paint film. Excellent self-cleaning performance, good gloss and color retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

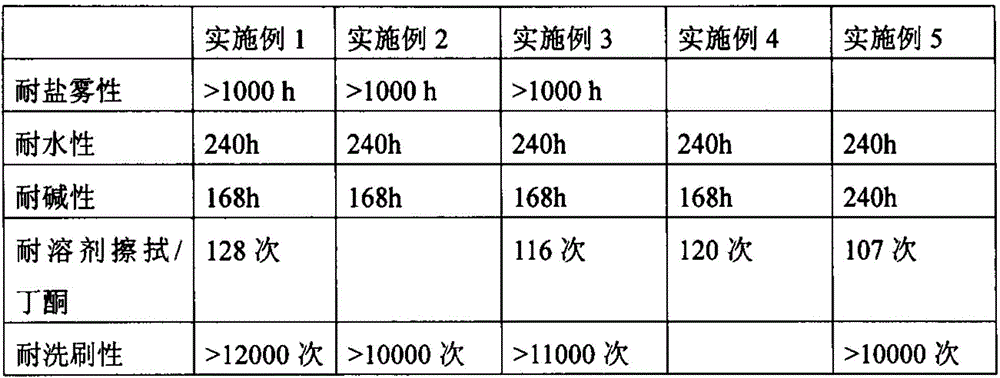

Examples

Embodiment 1

[0024] Water-dispersed fluorocarbon resin ZEFFLE SE-35038g, water 16.2g, titanium dioxide KRONOS219033g, TEGODispers715W2g, BYK0240.5g, 1,2-benzisothiazolinone 0.3g, curing agent 10g.

[0025] The method for preparing above-mentioned coating comprises the following process steps:

[0026] (1) Put all water 16.2g, TEGO Dispers715W2g, BYK0240.5g, 1,2-benzisothiazolinone 0.3g into the reaction kettle, and stir;

[0027] (2) Keep stirring and put 33g of titanium dioxide pigment into the reaction kettle, and stir for 0.5 to 1 hour;

[0028] (3) pass through the grinder after being mixed uniformly, and the particle size reaches 5 microns;

[0029] (4) Add 38g of water-dispersible fluorocarbon resin;

[0030] (5) Stir slowly for another 0.5 to 1 hour, filter to obtain mixture a;

[0031] (6) When in use, add 10g of curing agent to the mixture a, mix well before construction.

Embodiment 2

[0033] Water-dispersed fluorocarbon resin 56g, water 18.9g, water-based aluminum silver paste PCR2148g, NUOSPERSE FN2652g, TEGO Airex9310.8g, 8-hydroxyquinoline 0.3g, curing agent 14g.

[0034] The method for preparing above-mentioned coating comprises the following process steps:

[0035] (1) Put 14g of water, NUOSPERSE FN2652g, TEGO Airex9310.5g, and 0.3g of 8-hydroxyquinoline into the reaction kettle as required by the formula, and stir it;

[0036] (2) Add 56g of water-dispersible fluorocarbon resin;

[0037] (3) Stir and mix evenly;

[0038] (4) Keep stirring and put PCR2148g of water-based aluminum silver paste into the reaction kettle, and stir for 0.5 to 1 hour;

[0039] (5) Add 10.3g of TEGO Airex933 and 4.9g of water, stir slowly for 0.5-1 hour, filter to obtain mixture a;

[0040] (6) When in use, add 14g of curing agent to the mixture a, mix well before construction.

Embodiment 3

[0042] Water-dispersed fluorocarbon resin 42g, water 16.7g, pigment PV FAST YELLOW H3G3g, KRONOS219024g, TEGODispers740W3g, BYK0241g, 1,2-benzisothiazolinone 0.3g, curing agent 10g.

[0043] The method for preparing above-mentioned coating comprises the following process steps:

[0044] (1) Put all water 16.7g, TEGO Dispers740W3g, BYK0241g, 1,2-benzisothiazolinone 0.3g into the reaction kettle, and stir;

[0045] (2) Keep stirring and put the pigments PV FAST YELLOW H3G3g and KRONOS219024g into the reaction kettle, and stir for 0.5 to 1 hour;

[0046] (3) pass through the grinder after being mixed uniformly, and the particle size reaches 5 microns;

[0047] (4) Add 42g of water-dispersible fluorocarbon resin;

[0048] (5) Stir slowly for another 0.5 to 1 hour, filter to obtain mixture a;

[0049] (6) When in use, add 10g of curing agent to the mixture a, mix well before construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com