Perfluorocarbon powder paint with texture effect and preparation method thereof

A powder coating and fluorocarbon technology, applied in powder coatings, coatings and other directions, can solve the problems of pinholes, inconspicuousness and weak decorative effect of the coating, and achieve strong three-dimensional texture, high decorative effect and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

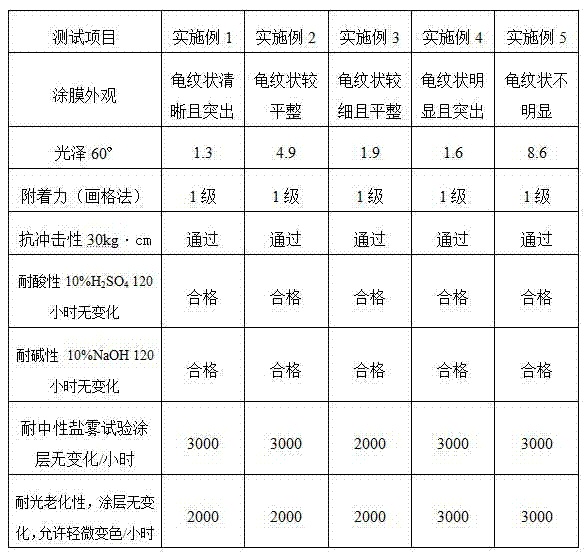

Examples

Embodiment 1

[0036] The composition and weight ratio of the fluorocarbon powder coating with texture effect provided in this example are: a self-sealing type with a hydroxyl value of 30-40 mgKOH / g FEVE resin, 200 parts, an isocyanate group equivalent of 250 g / eq, and a Tg of 65°C 65 parts of isophorone diisocyanate, 0.5 parts of accelerator, 30 parts of superfine barium sulfate, 0.5 parts of silicon dioxide adsorption acrylate leveling agent, 0.5 parts of benzoin, 3 parts of pigment.

[0037] (a) Weigh each component according to the proportion, place it in the mixing tank, fully mix and crush for 5 minutes;

[0038] (b) The crushed material is extruded through a twin-screw extruder or a single-screw extruder; the heating temperature of the extruder is controlled at 120°C;

[0039] (c) The extruded material is compressed into tablets, cooled, and crushed into a powder with a particle size (equivalent particle size D50) of 50 microns, and then sieved to obtain a fluorocarbon powder coating....

Embodiment 2

[0041] The composition and weight ratio of the fluorocarbon powder coating with texture effect provided in this example are: a self-sealing type with a hydroxyl value of 40-50 mgKOH / g FEVE resin 200 parts, an isocyanate group equivalent of 250 g / eq, and a Tg of 65°C 55 parts of isophorone diisocyanate, 1.0 parts of accelerator, 30 parts of superfine barium sulfate, 0.5 parts of silicon dioxide adsorption acrylate leveling agent, 0.5 parts of benzoin, 3 parts of pigment.

[0042] (a) Weigh each component according to the proportion, place it in the mixing tank, fully mix and crush for 5 minutes;

[0043] (b) The crushed material is extruded through a twin-screw extruder or a single-screw extruder; the heating temperature of the extruder is controlled at 120°C;

[0044] (c) The extruded material is compressed into tablets, cooled, and crushed into a powder with a particle size (equivalent particle size D50) of 50 microns, and then sieved to obtain a fluorocarbon powder coating. ...

Embodiment 3

[0046] The composition and weight ratio of the fluorocarbon powder coating with texture effect provided in this example are: 200 parts of FEVE resin with a hydroxyl value of 40-50 mgKOH / g, a self-sealing coating with an isocyanate group equivalent of 250 g / eq and a Tg of 75°C. 55 parts of type isophorone diisocyanate, 1.0 part of accelerator, 30 parts of titanium dioxide, 3 parts of polyester resin-loaded acrylate leveling agent, 0.5 part of benzoin, and 3 parts of pigment.

[0047] (a) Weigh each component according to the proportion, place it in the mixing tank, fully mix and crush for 5 minutes;

[0048] (b) The crushed material is extruded through a twin-screw extruder or a single-screw extruder; the heating temperature of the extruder is controlled at 120°C;

[0049] (c) The extruded material is compressed into tablets, cooled, and crushed into a powder with a particle size (equivalent particle size D50) of 50 microns, and then sieved to obtain a fluorocarbon powder coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com