High-performance waterborne inorganic paint and preparation method thereof

A water-based inorganic coating, high-performance technology, applied in the field of chemical engineering, can solve the problems of poor comprehensive properties such as plasticity, and achieve the effect of strong adhesion, significant adhesion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

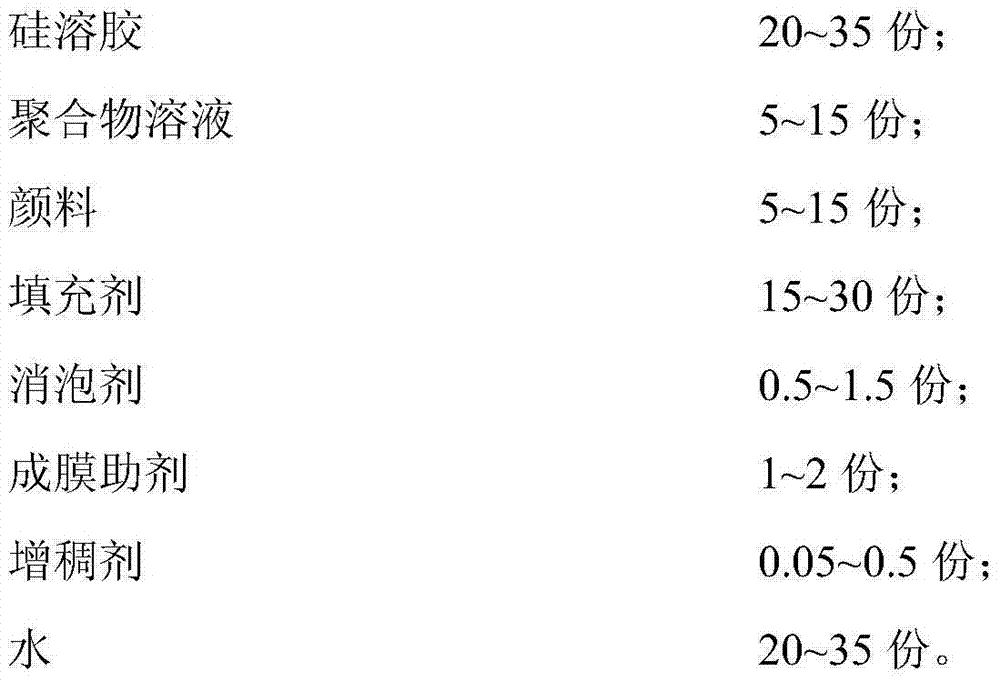

[0040] (1) Coating formula

[0041]

[0042] (2) Preparation steps

[0043] 1) At room temperature, add water and defoamer to the paint mixing tank, start stirring, then add pigments and fillers, stir at a speed of 500r / min for about 30min, and filter to obtain a uniform solution A;

[0044] 2) Add the silica sol and polymer solution described in the formula into the mixing tank, and stir at a speed of 300r / min for about 30min to obtain a uniform solution B;

[0045] 3) Add film-forming aids and thickeners to the homogeneous solution B obtained in step 2) while stirring, continue to stir at 300r / min for about 30min, and filter to obtain a homogeneous solution C;

[0046] 4) Add the homogeneous solution C obtained in step 3) dropwise into the paint mixing tank under stirring, the dropwise addition time is 1 hour, and stir at a rate of 1000r / min for about 2 hours, then filter, and the high-performance water-based Inorganic coatings.

Embodiment 2

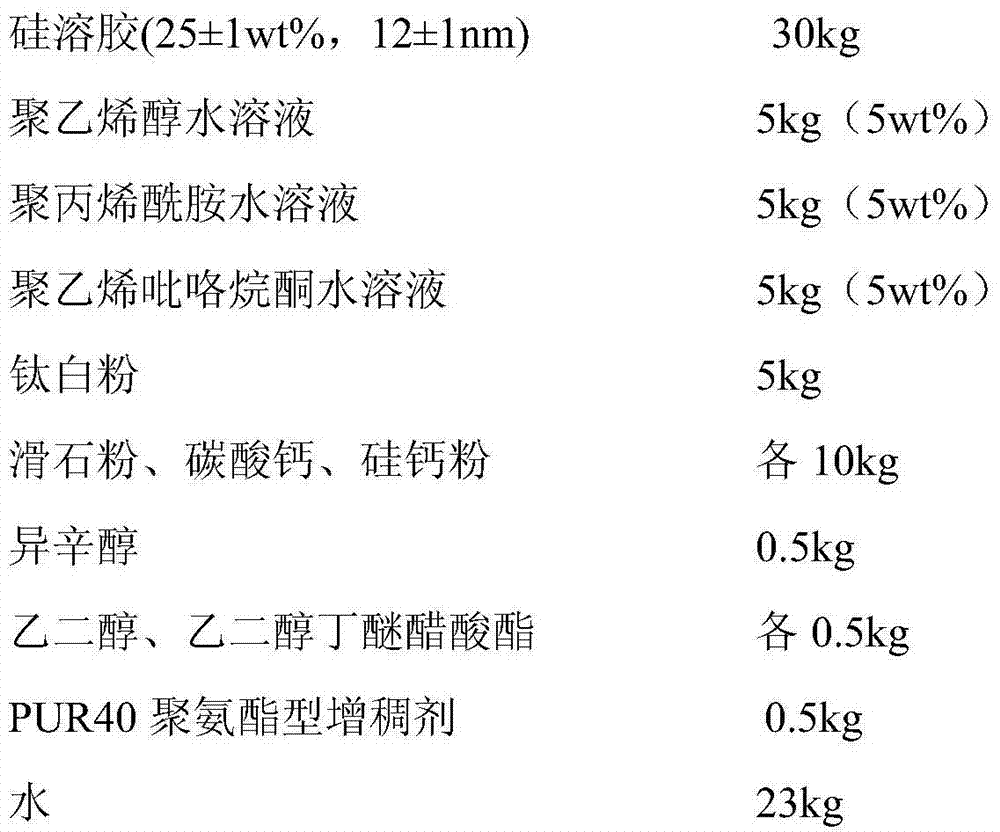

[0048] (1) Coating formula

[0049]

[0050] (2) Preparation steps

[0051] 1) At room temperature, add water and defoamer to the paint mixing tank, start stirring, then add pigments and fillers, stir at a speed of 500r / min for about 30min, and filter to obtain a uniform solution A;

[0052]2) Add the silica sol and polymer solution described in the formula into the mixing tank, and stir at a speed of 300r / min for about 30min to obtain a uniform solution B;

[0053] 3) Add film-forming aids and thickeners to the homogeneous solution B obtained in step 2) while stirring, continue to stir at 300r / min for about 30min, and filter to obtain a homogeneous solution C;

[0054] 4) Add the homogeneous solution C obtained in step 3) dropwise into the paint mixing tank under stirring, the dropwise addition time is 1 hour, and stir at a rate of 1000r / min for about 2 hours, then filter, and the high-performance water-based Inorganic coatings.

Embodiment 3

[0056] (1) Coating formula

[0057]

[0058]

[0059] (2) Preparation steps

[0060] 1) At room temperature, add water and defoamer to the paint mixing tank, start stirring, then add pigments and fillers, stir at a speed of 500r / min for about 30min, and filter to obtain a uniform solution A;

[0061] 2) Add the silica sol and polymer solution described in the formula into the mixing tank, and stir at a speed of 300r / min for about 30min to obtain a uniform solution B;

[0062] 3) Add film-forming aids and thickeners to the homogeneous solution B obtained in step 2) while stirring, continue to stir at 300r / min for about 30min, and filter to obtain a homogeneous solution C;

[0063] 4) Add the homogeneous solution C obtained in step 3) dropwise into the paint mixing tank under stirring, the dropwise addition time is 1 hour, and stir at a rate of 1000r / min for about 2 hours, then filter, and the high-performance water-based Inorganic coatings.

[0064] The performance ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com