Aqueous industrial coating material and production method thereof

An industrial and coating technology, applied in coatings and other directions, can solve the problems of water-based industrial coatings production and application performance gap, chemical properties and flexibility are not well solved, etc., to achieve excellent leveling and gloss, significant The effect of adhesion, strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

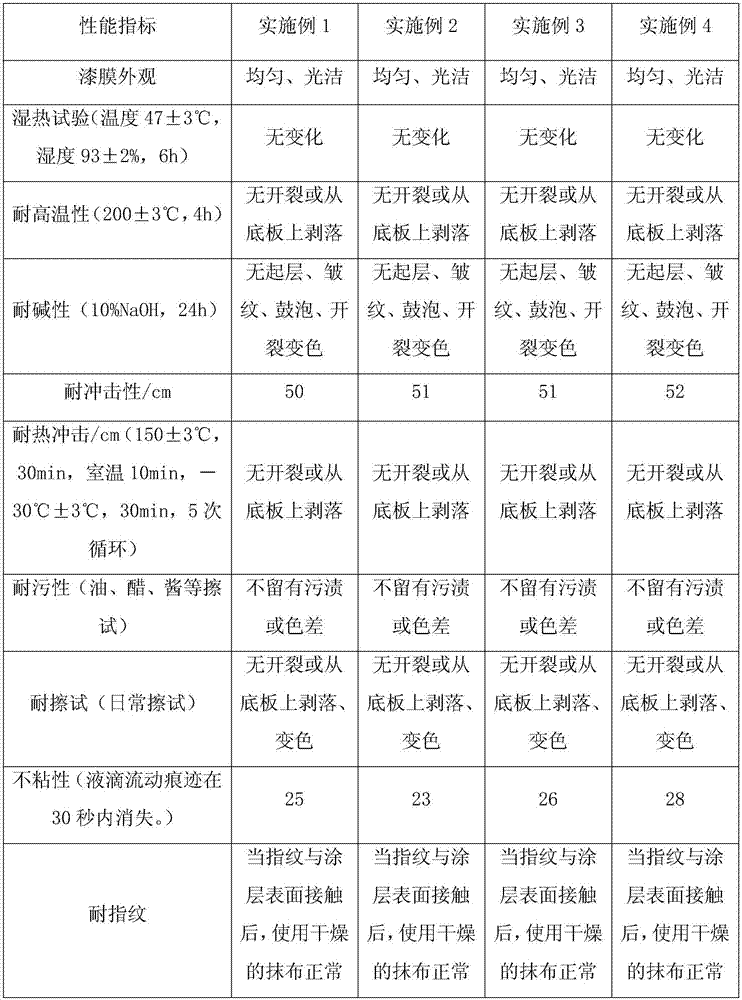

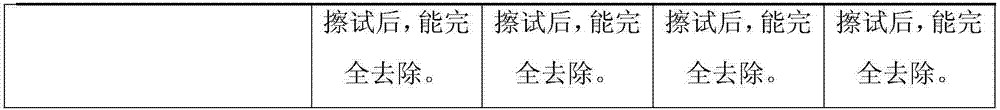

Examples

Embodiment 1

[0024] raw material:

[0025] 30 parts of silicone modified acrylic resin, 10 parts of methyl etherified melamine formaldehyde resin, 0.1 part of polyether modified polyorganosiloxane, 0.1 part of defoamer, 0.1 part of leveling agent, 5 parts of methanol, 5 parts of ether, 35 parts of deionized water.

[0026] production method:

[0027] S1. According to the above formula, put silicone-modified acrylic resin, methyl etherified melamine formaldehyde resin, methanol and ether into the dispersion container, stir while feeding, control the speed at 400-600 rpm, stir for 5-20 minutes, Obtain a uniform mixed solution;

[0028] S2, then add polyether modified polyorganosiloxane, defoamer, leveling agent, deionized water to the mixed solution, stir while feeding, control the speed at 400-600 rpm, stir for 5-20 Minutes, and then filtered, packaged, and put into storage to obtain water-based industrial coatings.

Embodiment 2

[0030] raw material:

[0031] 35 parts of silicone modified acrylic resin, 12 parts of methyl etherified melamine formaldehyde resin, 0.5 part of octyl succinic acid sulfonate, 0.5 part of defoamer, 0.5 part of leveling agent, 6 parts of ethanol, 6 parts of dipropyl ether, 40 parts of deionized water.

[0032] Above water-based industrial paint production method is the same as embodiment 1.

Embodiment 3

[0034] raw material:

[0035] 38 parts of silicone modified acrylic resin, 14 parts of methyl etherified melamine formaldehyde resin, 1.5 parts of perfluoroalkane sulfonate, 1.5 parts of defoamer, 1.5 parts of leveling agent, 8 parts of alcohol solvent (ethylene glycol and propylene glycol , the mass ratio is 1:1), 8 parts of diisopropyl ether, and 45 parts of deionized water.

[0036] Above water-based industrial paint production method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com