Material formula for insulating layer of cable with low dielectric loss

A cable insulation and layer material technology, applied in the field of cable manufacturing, can solve the problems of reducing energy utilization, destroying communication, energy loss, etc., achieving the effects of reducing dielectric loss, reasonable material matching, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

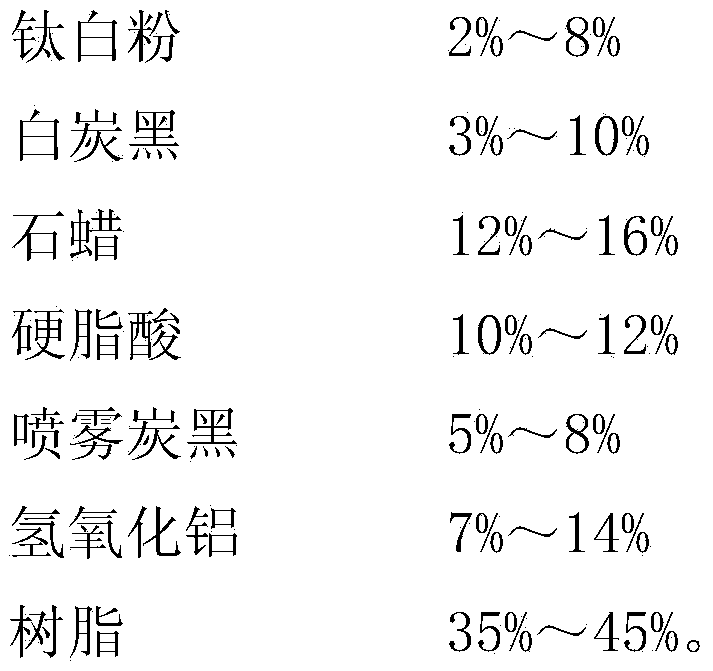

[0021] A low dielectric loss cable insulation material formula, the formula includes titanium dioxide, white carbon black, paraffin, stearic acid, spray carbon black, aluminum hydroxide and resin, and the mass percentage of each component is as follows:

[0022]

Embodiment 2

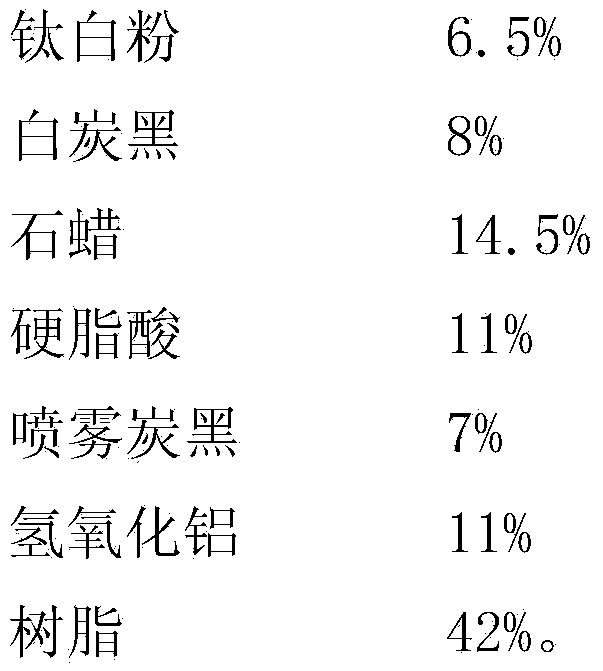

[0024] A low dielectric loss cable insulation material formula, the formula includes titanium dioxide, white carbon black, paraffin, stearic acid, spray carbon black, aluminum hydroxide and resin, and the mass percentage of each component is as follows:

[0025]

Embodiment 3

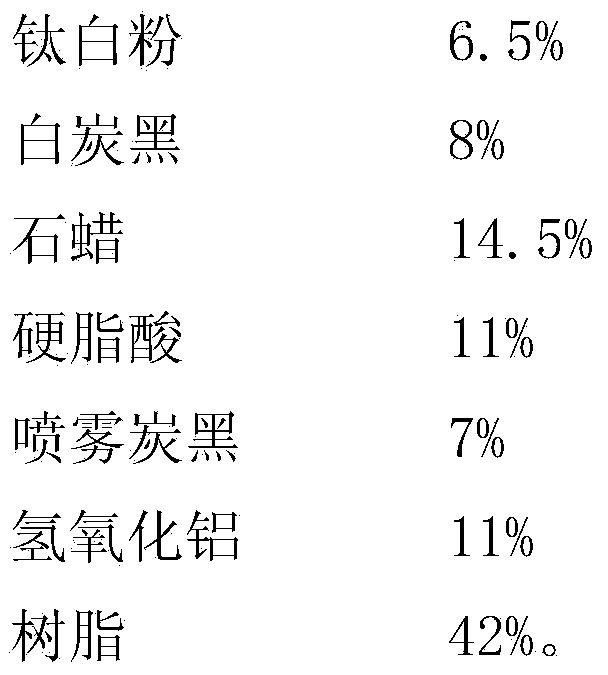

[0027] A low dielectric loss cable insulation material formula, the formula includes titanium dioxide, white carbon black, paraffin, stearic acid, spray carbon black, aluminum hydroxide and resin, and the mass percentage of each component is as follows:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com