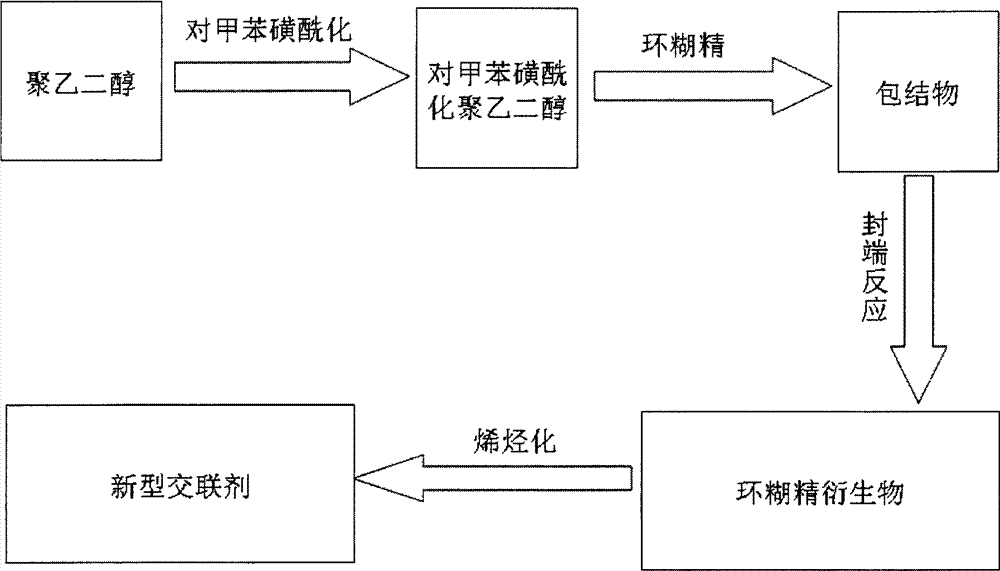

Preparation method of novel crosslinking agent based on cyclodextrin derivative

A technology of cyclodextrin and cross-linking agent is applied in the field of preparation of new cross-linking agent, which can solve the problems of material toughness decrease, and achieve the effect of improving toughness and strength and increasing cross-linking reaction sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

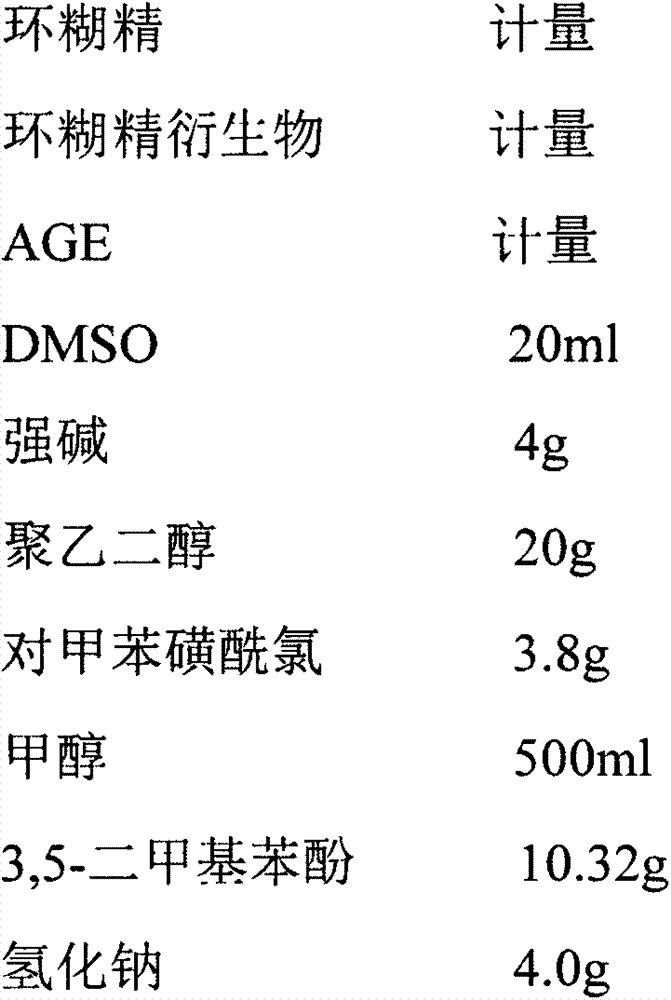

[0023] Dissolve PEG-4000 (20g, 5mmol) in dichloromethane solution (100ml), add p-toluenesulfonyl chloride (3.81g, 20mmol) in triethylamine (28ml) solution, mix well, react at room temperature for 12h, and use 150ml of 1mol / L Extract with dilute hydrochloric acid, add excess sodium carbonate solution to the organic phase, stir well until no bubbles are generated, filter, and concentrate the filtrate with a rotary evaporator. (temperature about 40 degrees), remove dichloromethane, drip the concentrated filtrate into excess ether, get white precipitate, suction filter, then dissolve the suction filtrate in 10ml of dichloromethane, filter the insoluble matter, and The solution was dropped into excess diethyl ether to obtain a white precipitate, which was filtered by suction and dried in vacuum for 24 hours to obtain a white product. The final yield is above 90%.

Embodiment 2

[0025] Dissolve cyclodextrin (25.6g, 26.4mmol) in 200ml of water to form a solution, dissolve the p-tosylated polyethylene glycol (5.98g, 1.386mmol) prepared above in 136ml of distilled water, and dissolve p-toluenesulfonyl Add the aqueous solution of polyethylene glycol to the aqueous solution of cyclodextrin, ultrasonically treat for 30 minutes, stir overnight at room temperature, centrifuge the formed inclusion complex, and then put it in a vacuum drying oven to dry at 70°C to obtain the inclusion complex , the molar ratio of cyclodextrin to p-tosylated polyethylene glycol is 19:1. The final yield is above 92%.

Embodiment 3

[0027] 3,5-Dimethylphenol (10.32g, 84mmol) was dissolved in 144ml of DMF, and then slowly added dropwise into a round bottom flask of sodium hydride (4.0g). The solution turned brown and nitrogen was used as a protective gas during this process. Take the clathrate (13.94g) and dissolve it in 56ml of DMF, then add the above brown solution and stir for 12h. Divide the reaction solution into two beakers, add about 200ml of anhydrous methanol respectively, and filter to obtain a precipitate. Wash the precipitate with methanol twice, 20ml each time, dissolve the obtained precipitate in 40ml DMSO, then add 240ml of anhydrous methanol to obtain a precipitate, filter to obtain the precipitate, and wash with anhydrous methanol twice, each time 20ml. Then dissolve the precipitate in DMSO, add water to form a precipitate, filter the precipitate, and finally vacuum dry the precipitate in a vacuum drying oven at 110° C. overnight. The final yield was around 39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com