Composite material used for casting aluminum alloy box body oil duct and method thereof

A technology of casting aluminum alloy and composite materials, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problem that the tank oil passage cannot meet the sealing requirements, shorten the processing cycle, reduce processing costs, meet Effect of tightness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

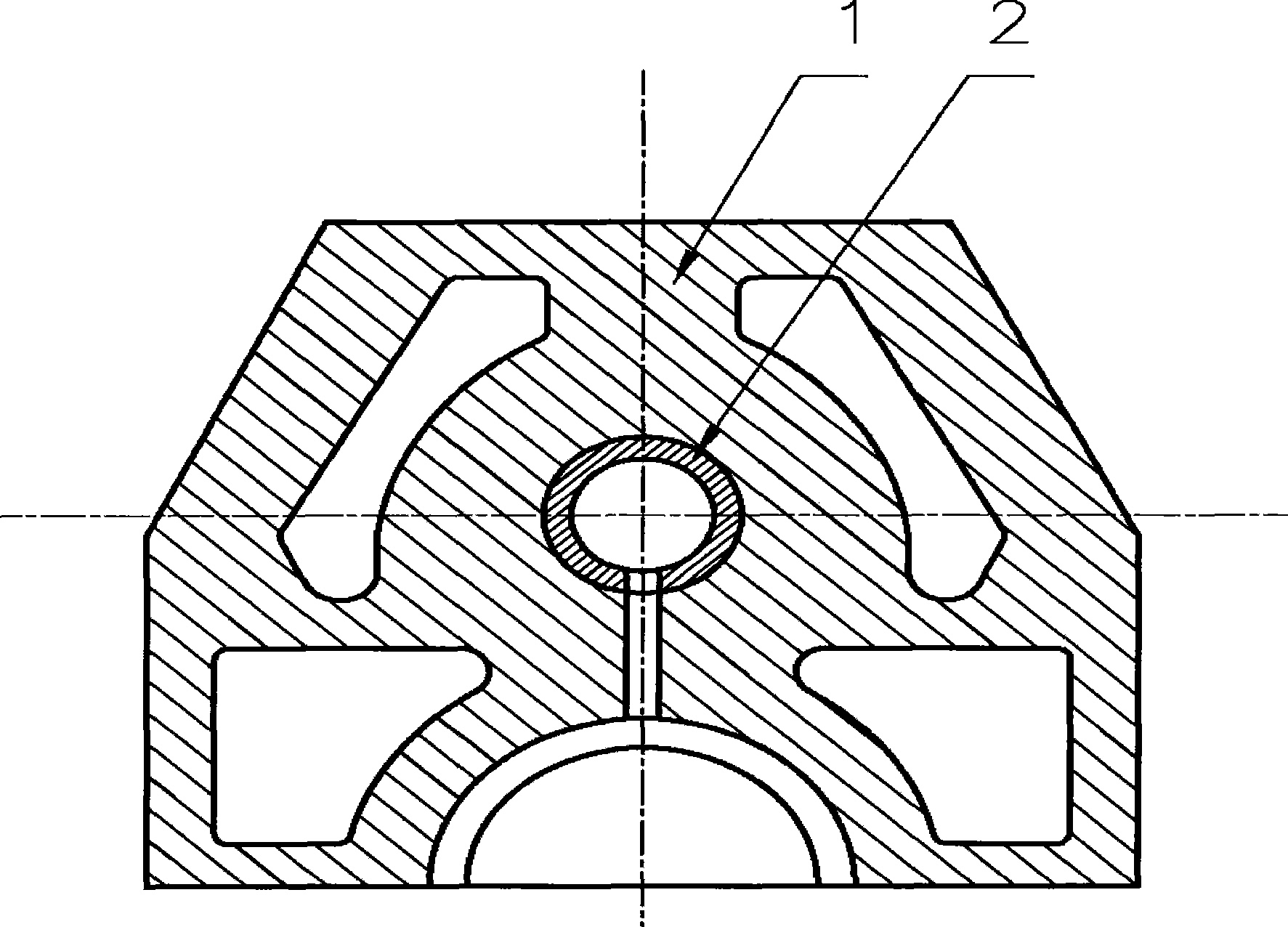

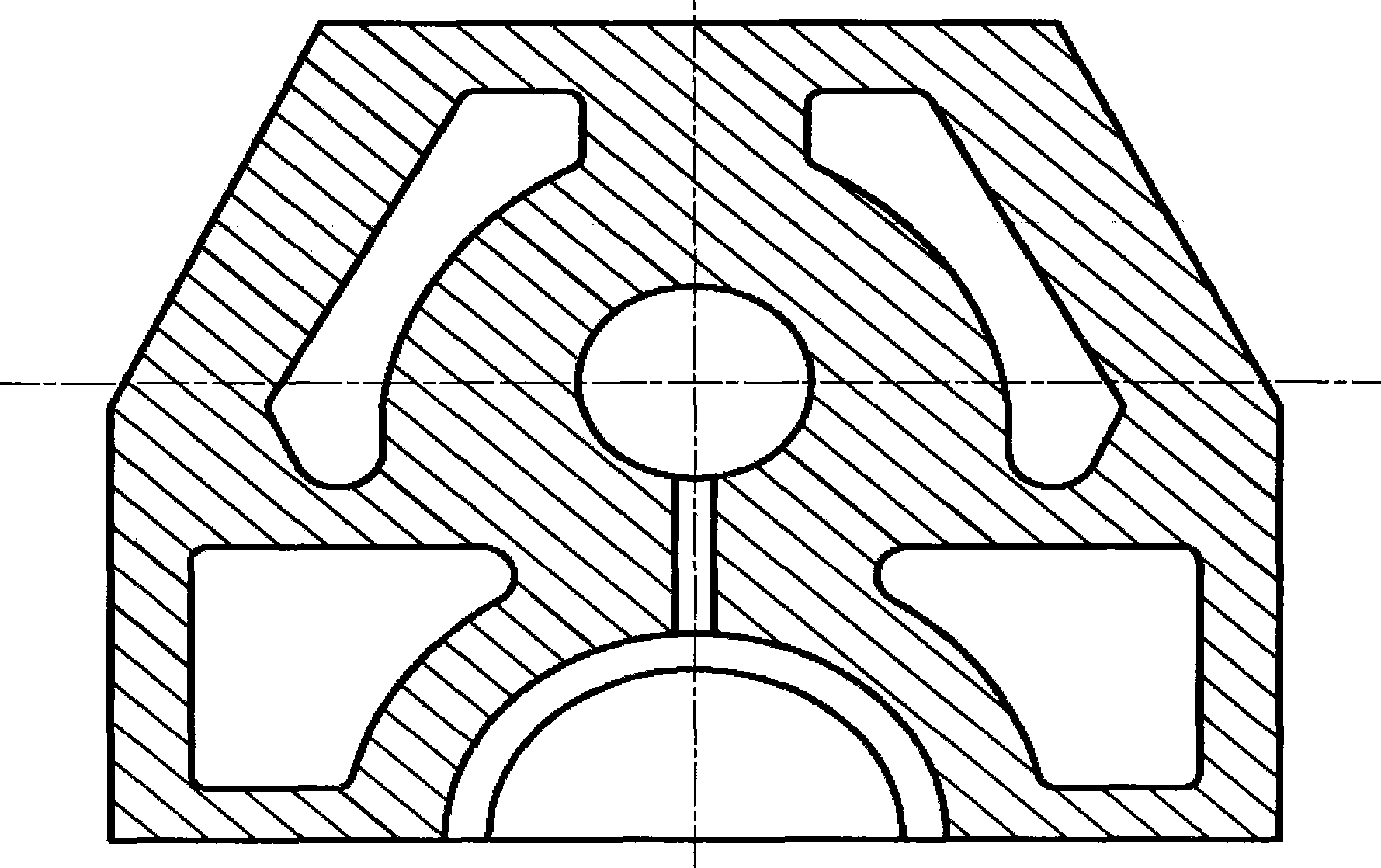

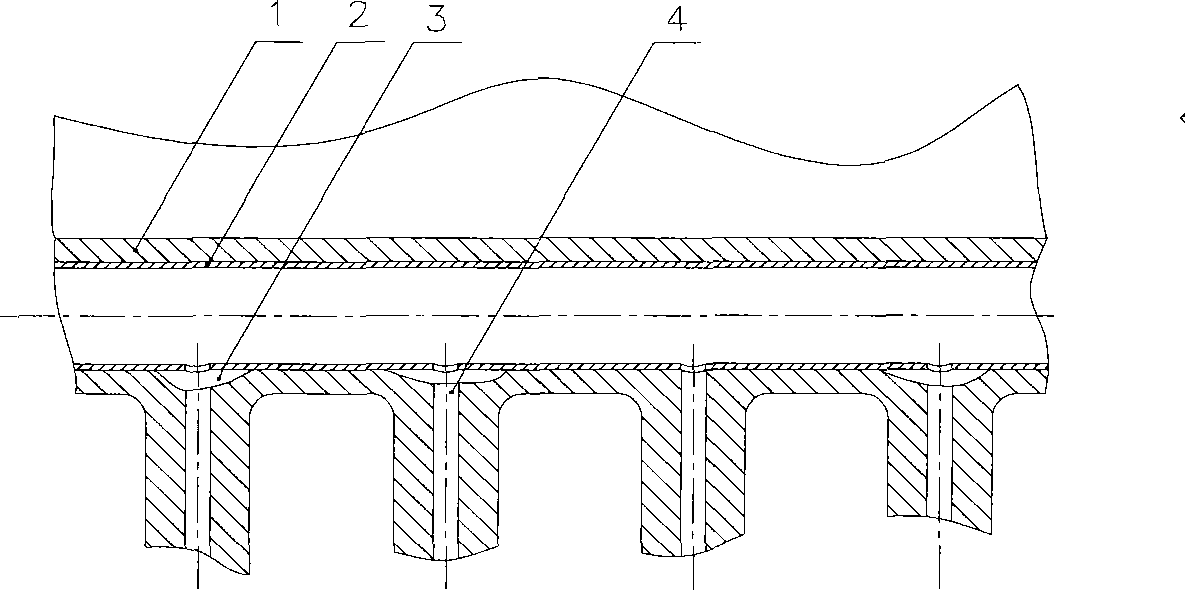

[0034] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0035] The composite material for casting aluminum alloy box oil passage provided by the present invention includes metal shot, iron powder, raw sand and self-setting resin sand binder. The thermophysical parameters of the composite material can be continuously adjusted according to different requirements.

[0036] Wherein, the diameter of the metal shot is 0.3-0.5mm; the particle size of the iron powder is 70-100 mesh; the particle size of the raw sand is 50-100 mesh; the self-setting resin sand binder is a resin binder + Curing agent.

[0037] Wherein, the proportions of the metal shot, iron powder, raw sand and self-setting resin sand binder in the composite material are 50%-60%, 30%-40%, 10%-20% and 1.5%- 2%.

[0038] Among them, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com