High-oil-pressure and large-drift-diameter combined reversing valve for electric high-voltage switch hydraulic mechanism

A high-pressure switch and hydraulic mechanism technology, which is applied to multi-way valves, valve details, valve devices, etc., can solve problems such as loose structures and complicated oil circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

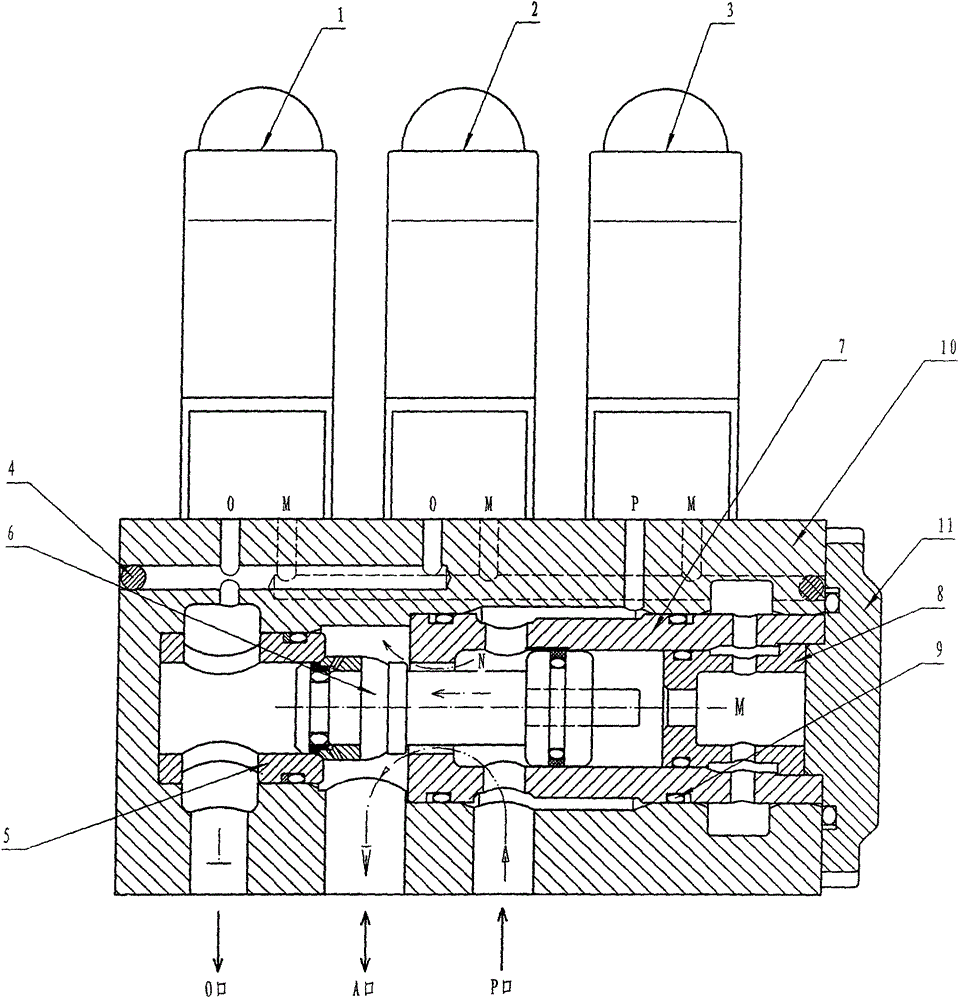

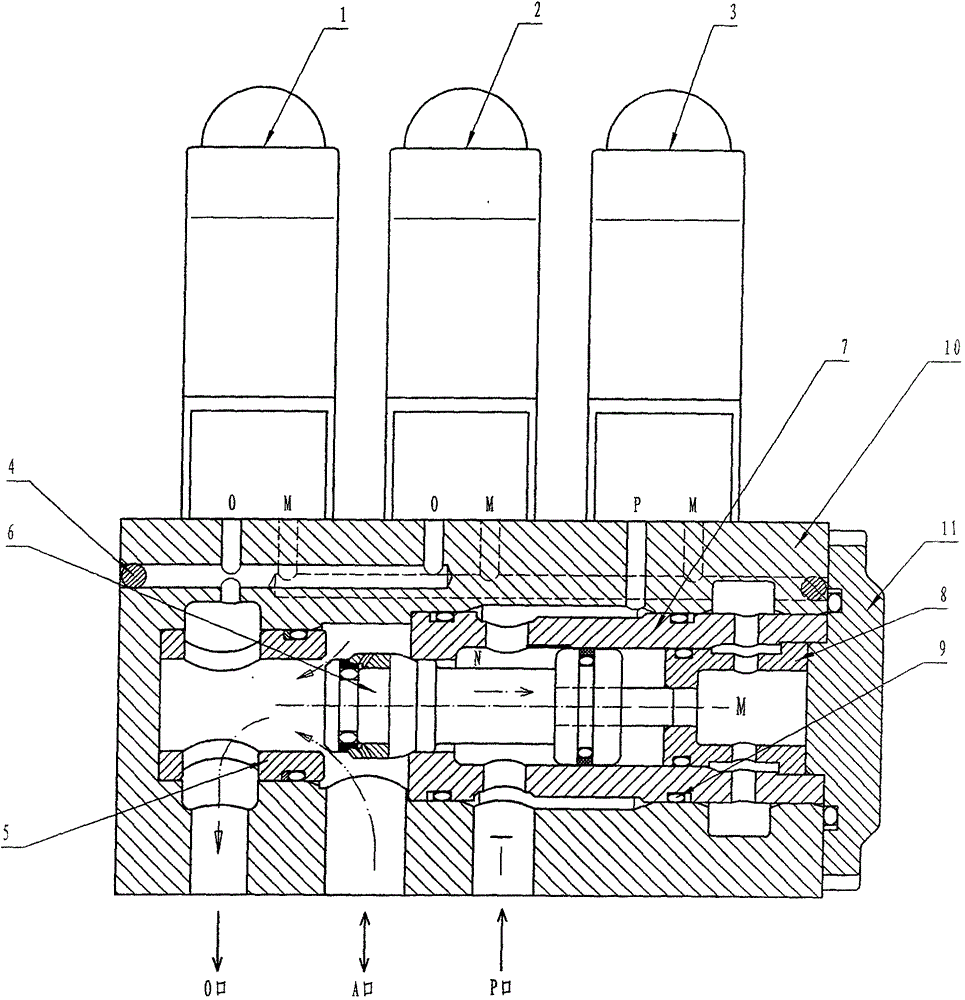

[0021] The embodiments are further described below in conjunction with the accompanying drawings.

[0022] refer to figure 1 , figure 2 , the present invention includes a valve body 10, an end cover 11, a valve core 6, a valve body oil channel and an auxiliary mechanism for electromagnetic pilot control, and its main innovations are:

[0023] 1. The auxiliary mechanism of the valve body is an electromagnetic pilot valve, which is installed on the valve body 10 and communicates with the O port, P port and M cavity on the valve body 10 through the oil passage, and the oil passage on the valve body 10 through the ball plug 4 cut off for external use.

[0024] 2. The inner cavity of the valve body 10 is provided with a short valve sleeve 5, a valve core 6 and a long valve sleeve 7, which are sealed and installed in the inner cavity of the valve body 10 through the end cover 11. The cooperation between each valve sleeve and the valve body 10 is an inlay fit And through the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com