Electric grease injecting machine

A butter filling and electric technology, applied in the directions of engine components, engine lubrication, mechanical equipment, etc., can solve the problems of shortening the service life of the air pump unit, affecting the working environment of the operator, complex structure of the reversing mechanism, etc. Stable, good sealing effect, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

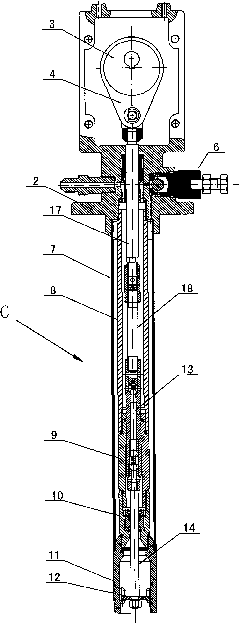

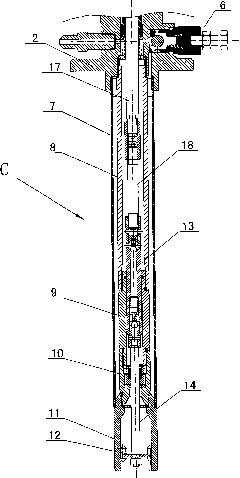

[0033] see figure 1 , with reference to Figure 2-5 , the electric butter filling machine involved in the present invention mainly includes a slender cylindrical oil pumping device C; the oil pumping device C sequentially includes a coaxial outer casing 7 and an inner connecting pipe 8 from the inside to the outside; along the inner connecting pipe 8 In the axial direction, there are transmission rod 17, connecting rod 18, plunger rod 13, and pump body 9 connected to each other in sequence from top to bottom. The pump body 9 is connected with the oil inlet casing 11 through the oil inlet valve seat 10; the oil inlet sleeve The pipe 11 is provided with a lifting rod 14 connected to the pump body 9, and the lifting rod 14 is provided with a lifting plate 12; the transmission rod 17 drives the pump body 9, the lifting rod 14 and the pump body 9 through the connecting rod 18 and the plunger rod 13. The lifting plate 12 reciprocates up and down along the axial direction of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com