Intelligent intermediate-frequency ultrasonic atomizing cultivation machine

An ultrasonic nebulizer, ultrasonic atomization technology, applied in cultivation, soilless cultivation, botanical equipment and methods, etc., can solve the problems of high driving circuit voltage, easy leakage of droplets, low safety, etc., and achieve atomization The effect of large quantity, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

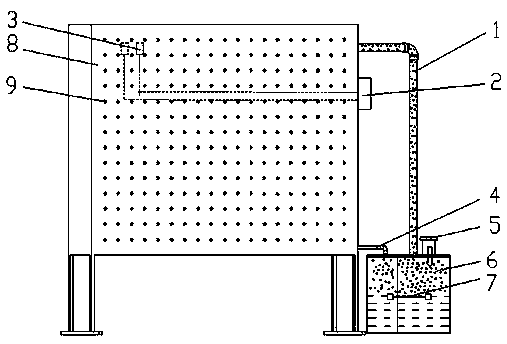

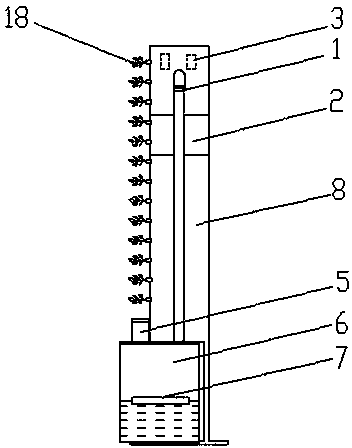

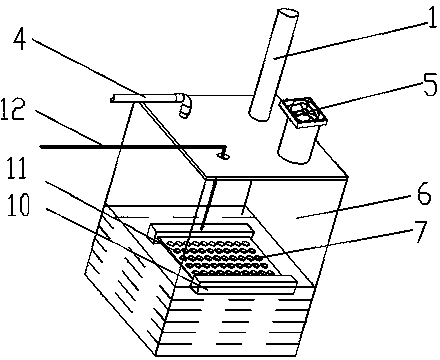

[0020] combine figure 1 On the front wall of the cultivation box 8, evenly drill the planting hole 9 with a diameter of 2 cm, insert a plant 18 in the hole, and fix the contact with a sponge 17 to prevent air leakage; the temperature and humidity sensor 3 is supported by iron wire, and is placed in the cultivation box 8 ( Such as Figure 8 ), connected with the MCU, the right outer side of the cultivation box 8 is installed with a control cabinet 2, which contains an MCU and a relay, and the MCU receives the temperature and relative humidity values measured by the temperature and humidity sensor 3 to control the rotational speed and relative humidity of the axial flow fan 5 Ventilation time, the spray volume and spray time of the intermediate frequency ultrasonic atomizer 7, thereby controlling the temperature and humidity of the root zone environment, and realizing intelligent control; Figure 4 , Figure 7 , a total of 50 intermediate-frequency ultrasonic nebulizers 7 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com