pc steel casing

A technology of steel and casing, applied in the field of casing for PC steel, can solve the problems of poor cement slurry inflow, decrease of cement slurry compressive strength and shear fracture strength, easy cracking and fracture of cement slurry, etc., to achieve an integrated The effect of improving performance and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

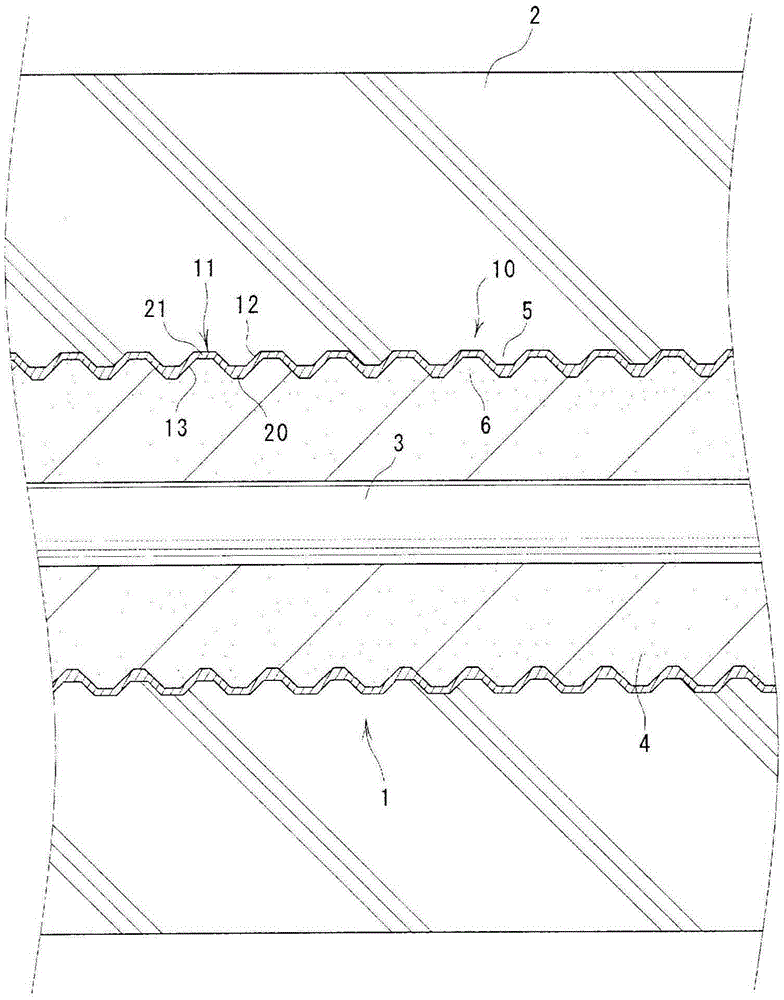

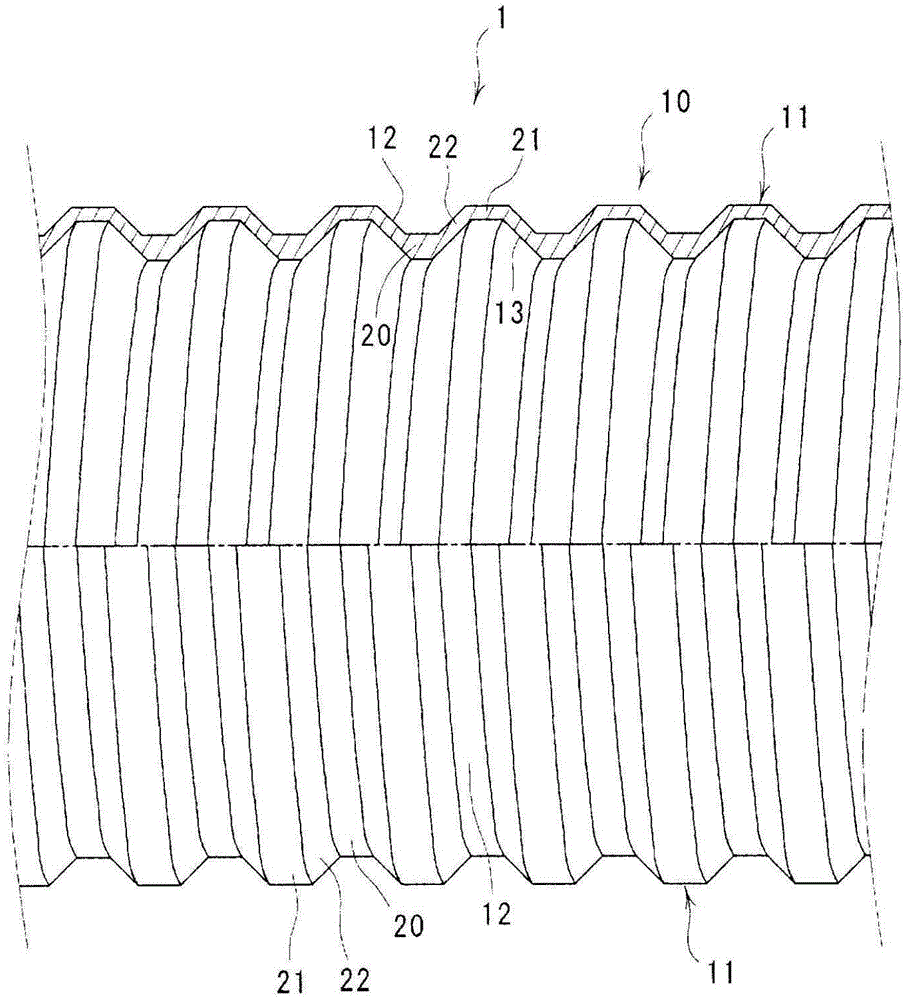

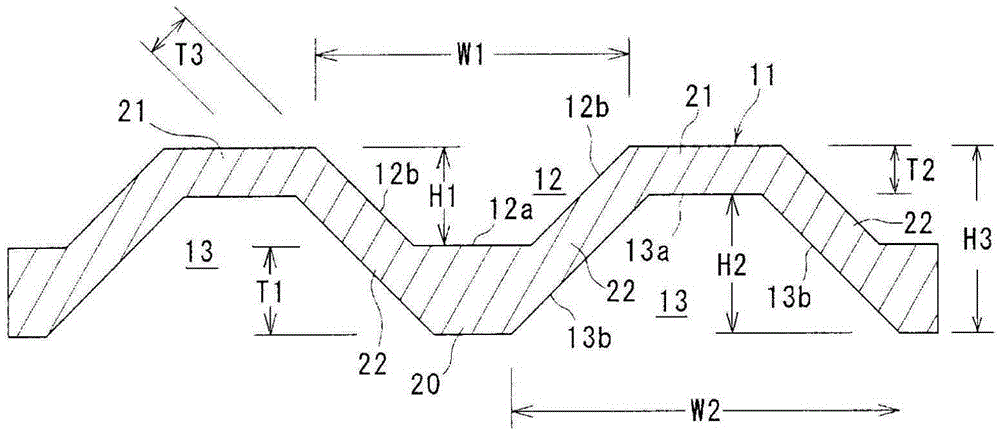

[0032] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The bushing 1 for PC steel materials according to one embodiment of the present invention is used, for example, when constructing a prestressed concrete structure such as a PC girder bridge by post-tensioning.

[0033] The casing 1 for the PC steel is as figure 1 As shown, for example, a tubular body 10 made of high-density polyethylene resin is used to be embedded in a concrete structure 2 and inserted through a PC steel material 3 that introduces prestress into the concrete structure 2. The interior of the main body 10 is filled with cement slurry 4 .

[0034]A high-density polyethylene resin is used as the raw material of the tubular body 10 for the following reasons. That is, the high-density polyethylene resin is light, rust-free, and non-corrosive, and has excellent molding processability. In addition, due to its high rigidity and impact resistance, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com