Method for producing short-chain polyfunctional polyether polyols utilizing superacid and double-metal cyanide catalysis

A technology of double metal cyanide and short-chain polyether, applied in the field of producing short-chain polyether polyols

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

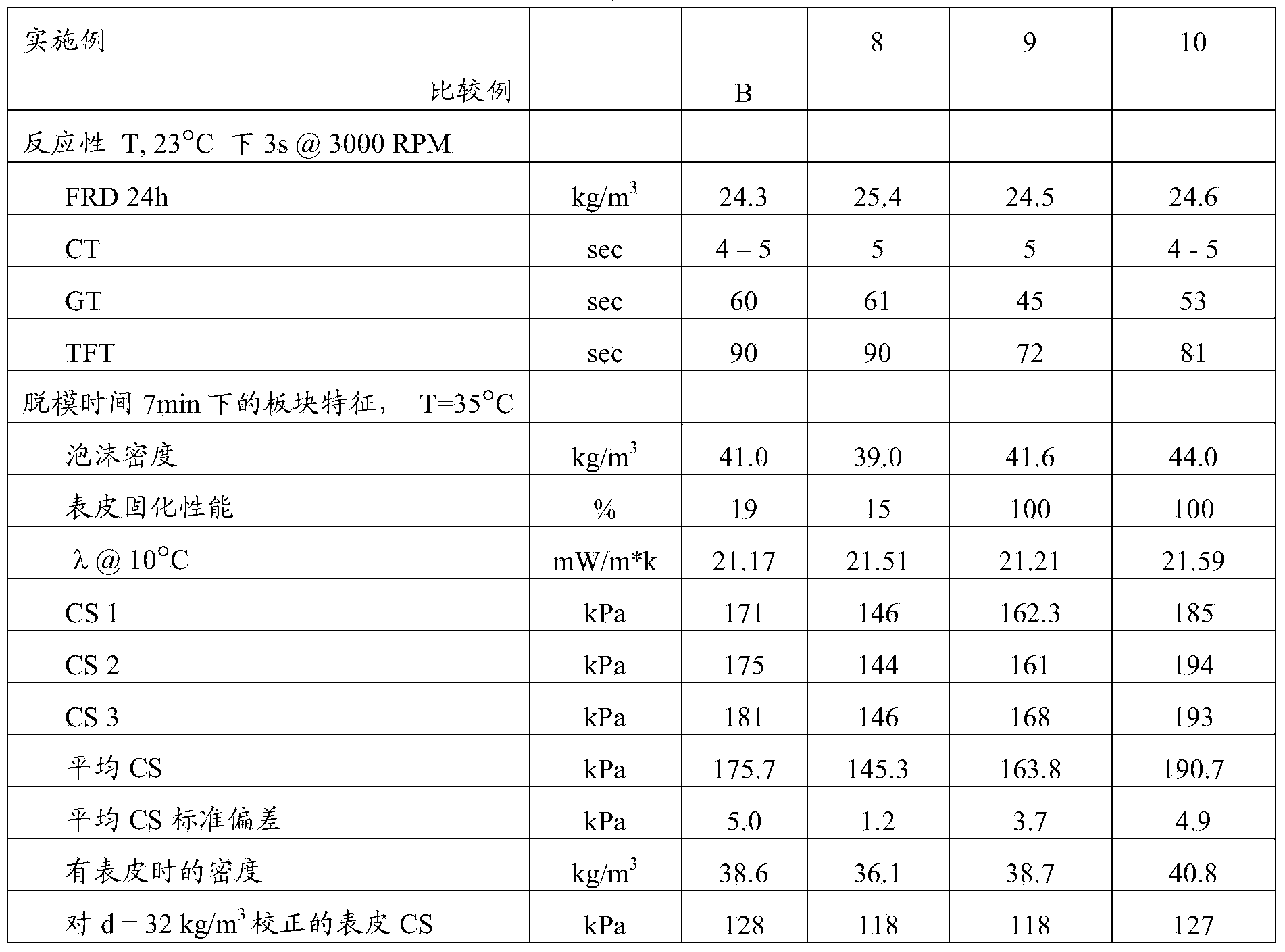

Examples

Embodiment 1 to 7 and comparative example A

[0067] "Sorbitol", greater than (>) 99% pure, available from Aldrich;

[0068] "Glycerin", greater than (>) 99.5% pure, available from Aldrich;

[0069] "VORANOL TM CP450" is a glycerol initiated oxypropylene triol polyether polyol having a molecular weight of about 450, available from The Chemical Company;

[0070] "PO" is propylene oxide, >99.9% pure, available from The Dow Chemical Company;

[0071] "TFA" is trifluoromethanesulfonic acid (trifluoromethanesulfonic acid), >98% pure, available from Fluka; and

[0072] "DMC" is a double metal cyanide catalyst trade name ARCOL TM A3, available from Bayer.

[0073] Tests are performed according to the following methods:

[0074] "Hydroxyl value" is measured in mg / g of potassium hydroxide (KOH) according to the protocol of ASTM D4274D;

[0075] "Acid value" is measured in potassium hydroxide (KOH) mg / g and is determined by potentiometric titration of the sample in methanol with standard KOH in methanol (0.01 N: certified, ...

Embodiment 1

[0085] 686.5g (3.77mol) of crystalline sorbitol and 0.17g of 85% phosphoric acid were placed in a 5L stainless steel alkoxylation reactor. The reactor was thermostated at 120°C and a vacuum (1 mbar) was applied to the reactor. Once the sorbitol had melted inside the reactor, stirring was started (200 rpm) and a nitrogen sparge was applied from the bottom of the reactor while the vacuum pump was still running so that the total pressure inside the reactor was maintained at 10 mbar. The reaction mixture was dried under these conditions for 2 h. Turn off the sparge and vacuum, reduce the reactor temperature to 100 °C, and the reactor with 1 bar (100 kPa) N 2 Pressurize, open, and add 0.03 g trifluoromethanesulfonic acid (22 ppm based on product weight). The reactor was closed; vacuum was applied to the reactor to reduce the internal pressure to below 1 mbar. The stirring rate was increased to 400 rpm and PO (657 g, 11.31 mol) was fed into the reactor at an average feed rate of ...

Embodiment 2

[0088] 701.9 g (1.97 mol) of polyether polyol from Example 1 and DMC catalyst (0.247 g, 180 ppm based on product weight) were placed in a 5L stainless steel alkoxylation reactor. The reactor was thermostated at 150°C. Vacuum was applied to the reactor to reduce the internal pressure to below 1 mbar and agitation at 400 rpm was applied. PO (686 g, 11.81 mol) was fed into the reactor at an average feed rate of 6.2 g / min over a period of 110 min. The initial reaction rate was measured to be 6x10 -5 g / ppm / min with a reaction rate of 2x10 measured at the end of the PO feed -4 g / ppm / min. After the feed was complete, the total pressure in the reactor was equilibrated to 0.2 bar (20 kPa) over 130 min. The product was vacuum stripped at 120 °C for 1 h. A colorless viscous liquid is obtained.

[0089] The resulting polyether polyol has the following properties: OH value: 480 mg KOH / g; acid value: 0.09 mg KOH / g; total unsaturation: 0.0046 meq / g; water: 350 ppm; total volatile matte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com