Method for determination of detergency and dispersibility of engine oil

A technology for cleaning and dispersing engine oil, applied in the direction of optical testing flaws/defects, etc., can solve the problems of misalignment, low measurement accuracy, time-consuming measurement process, etc., to achieve the effect of reducing errors and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The following is a preferred embodiment given by the inventor. It should be noted that the following embodiment is only a preferred way of implementing the technical solution of the present invention, and the protection scope of the present invention is not limited to this embodiment.

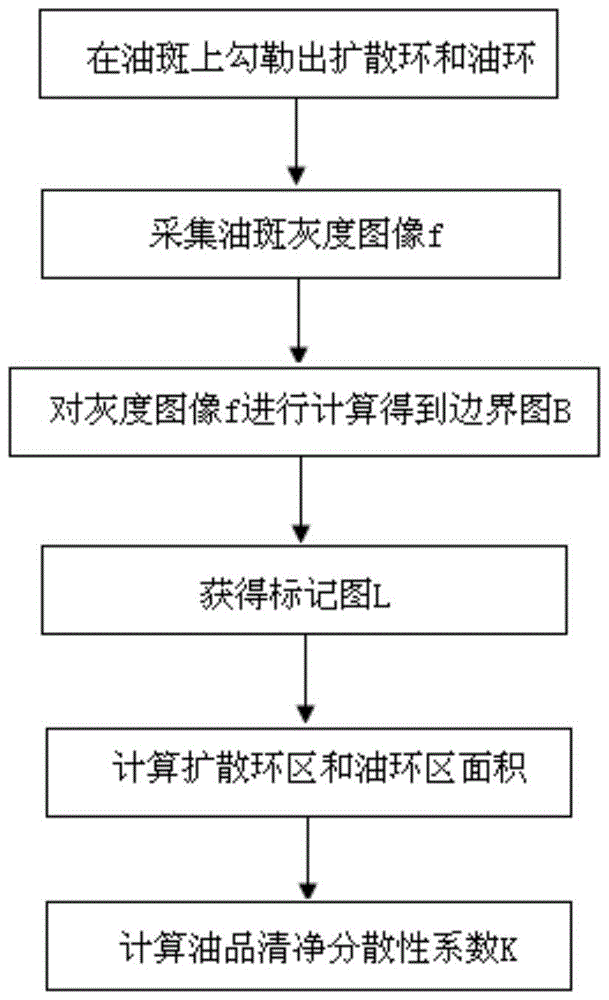

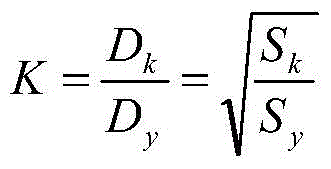

[0061] Reference figure 1 The method for measuring the cleanness and dispersion of engine oil of this embodiment specifically includes the following steps:

[0062] Step S1: Use a metal or glass rod to drop the oil sample just taken out of the engine on the filter paper. The filter paper uses a 9cm diameter double circle brand medium-speed quantitative filter paper.

[0063] Step S2: After standing for 3 hours, an oil spot is obtained, and the diffusion ring and the oil ring are manually traced on the oil spot with a fine black carbon pen.

[0064] Step S3: Use a camera to collect a grayscale image of the oil spot, and input the grayscale image of the oil spot into the computer. The size of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com