Device for Accurately Measuring Bending Stiffness in High and Low Temperature Environments

A precise measurement, high and low temperature technology, applied in the direction of measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problem that the laser emitter cannot be located on the component, follow the three-dimensional displacement of a certain point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

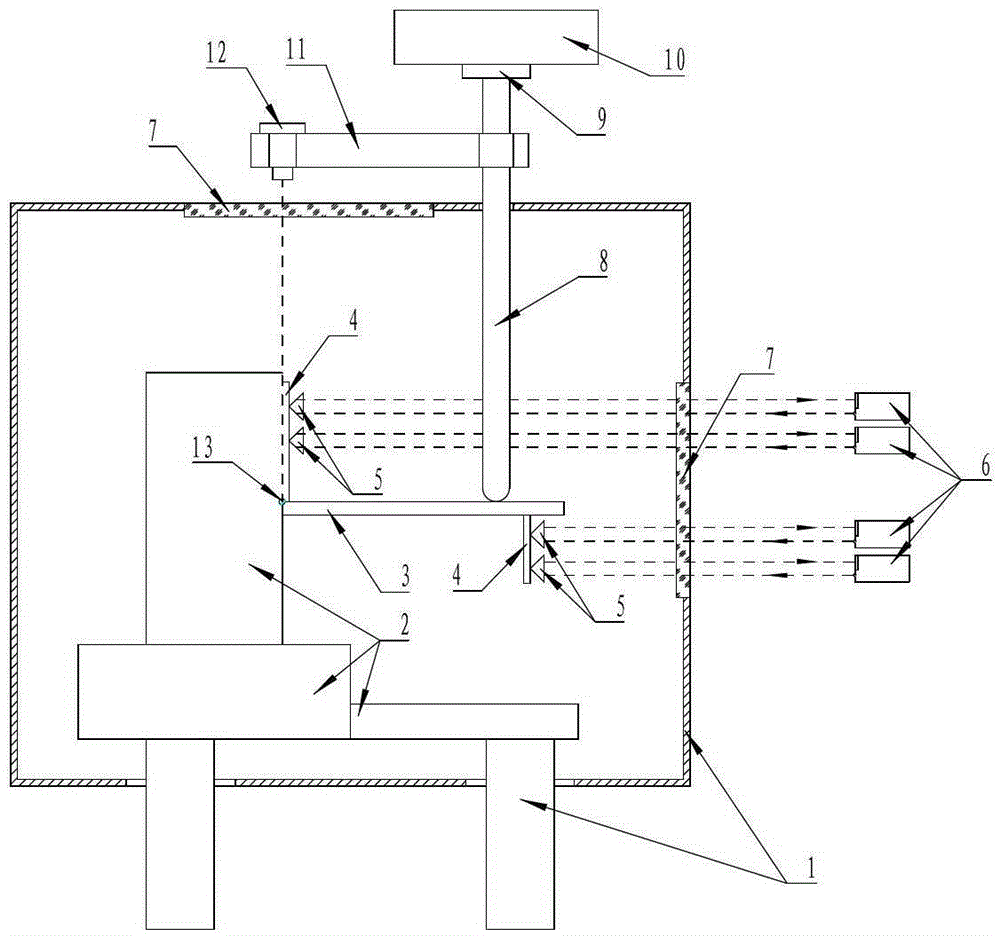

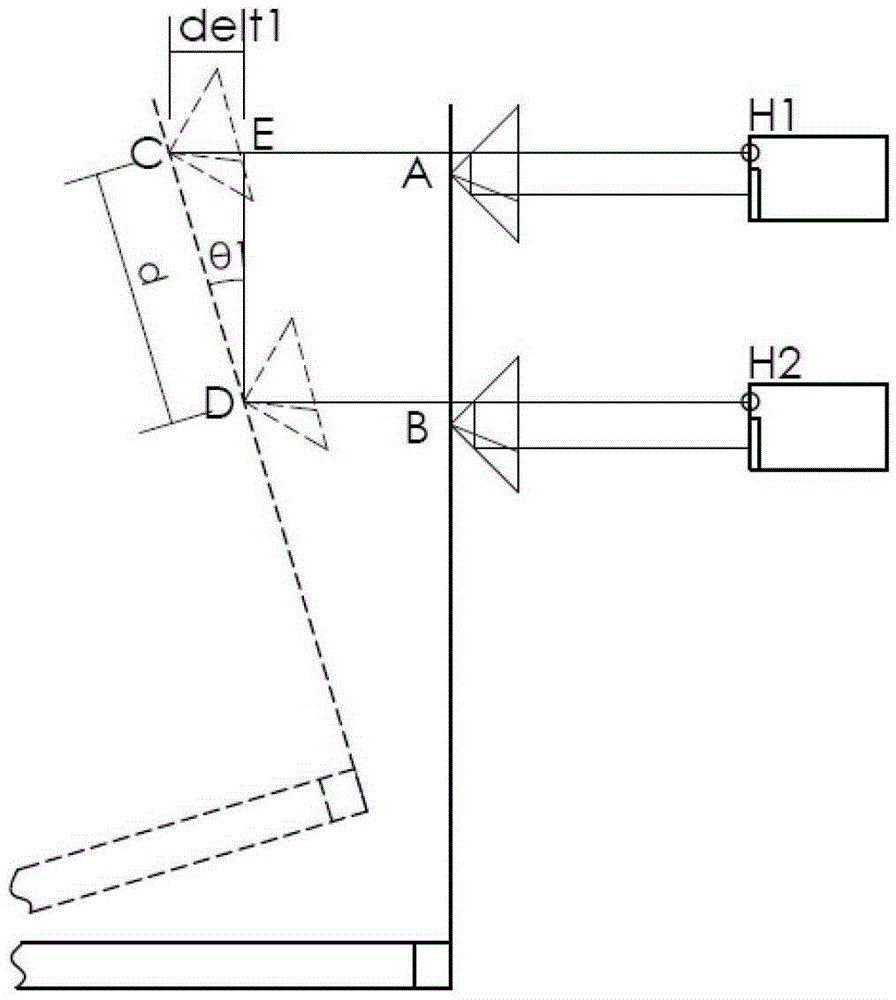

[0026] combine Figure 1 to Figure 3 , a device for accurately measuring bending stiffness in a high and low temperature environment, including an optical lens 12, a high rigidity rod 8, a force sensor 9, a three-dimensional mobile platform 10, a mirror mirror 5, a Doppler laser, etc.

[0027] The test piece 3 and its mounting seat 2 are placed in the high and low temperature box 1, one end of the high stiffness rod 8 is fixedly connected to the three-dimensional mobile platform 10, and the other end of the high stiffness rod 8 is a smooth spherical surface And act vertically on the tested object 3 , a force sensor 9 is installed between the high rigidity rod 8 and the three-dimensional mobile platform 10 .

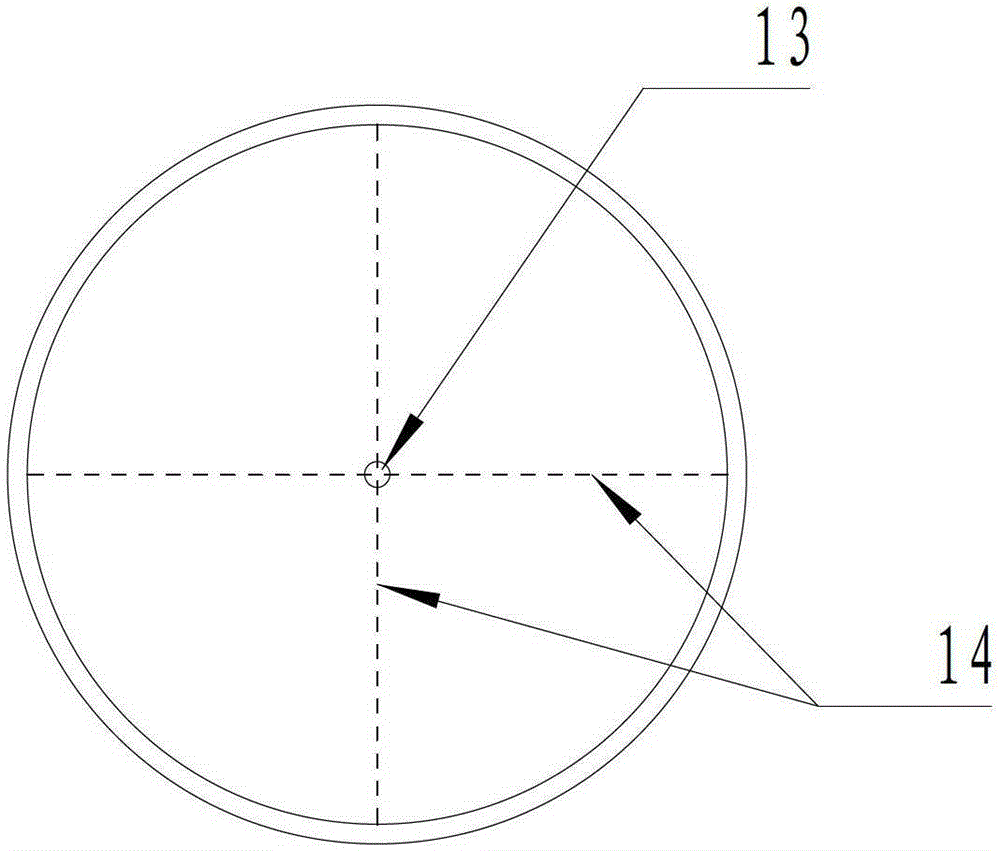

[0028] The optical lens 12 is vertically fixed on the high rigidity rod 8 through the mount 11 and is located outside the high and low temperature box 1. There is a reticle with a crosshair 14 inside the optical lens 12, and the optical lens 12 is facing The observation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com