Fuel oil filter paper and method for preparing same

A fuel filter and base paper technology, applied in filter paper, separation methods, chemical instruments and methods, etc., can solve the problems of high requirements for fuel filter paper and limited filtration efficiency of fuel filter paper, so as to increase the effective contact area, improve oil quality and fuel consumption Use efficiency, increase the effect of filter gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing the above-mentioned fuel filter paper, comprising: A) combining polyester fibers with a weight percentage greater than 0 and less than or equal to 38%, wood pulp fibers with a weight percentage greater than 42% and less than 100%, and a weight percentage greater than 0 and less than Wet strength agent equal to 1% is mixed and pulped, and paper-making is obtained to obtain wet paper; B) the wet paper is pressed and dried to obtain base paper; C) the weight percentage of coating on the base paper is greater than 0 and less than or equal to 20% The resin is dried and creped to obtain fuel filter paper.

[0032] Wherein, the polyester fiber, wood pulp fiber, wet strength agent and resin are the same as those described above, and will not be repeated here.

[0033] Mix polyester fiber, wood pulp fiber and wet strength agent to prepare pulp, and make it to obtain wet paper, which is then pressed and dried to obtain ba...

Embodiment 1

[0041] 1.1 Base paper weight is 75g / m 2 , fuel filter paper quantitative is 92g / m 2 , 28% of southern pine needle pulp, 17% of Brazilian eucalyptus hardwood pulp, 36.4% of polyester fiber and 0.1% of PAE wet strength agent were mixed and prepared, and wet paper was obtained after papermaking. The polyester fiber has a diameter of 12.8 μm and a length of 4 mm.

[0042] 1.2 Place the wet paper obtained in 1.1 on an inclined wire paper machine with a machine speed of 50m / min. When the dryness of the paper is 96%, use 18.5% acrylic resin for film transfer coating, and press it when the dryness reaches 85%. The embossing roll has a tooth height of 2.2 mm to obtain a fuel filter paper.

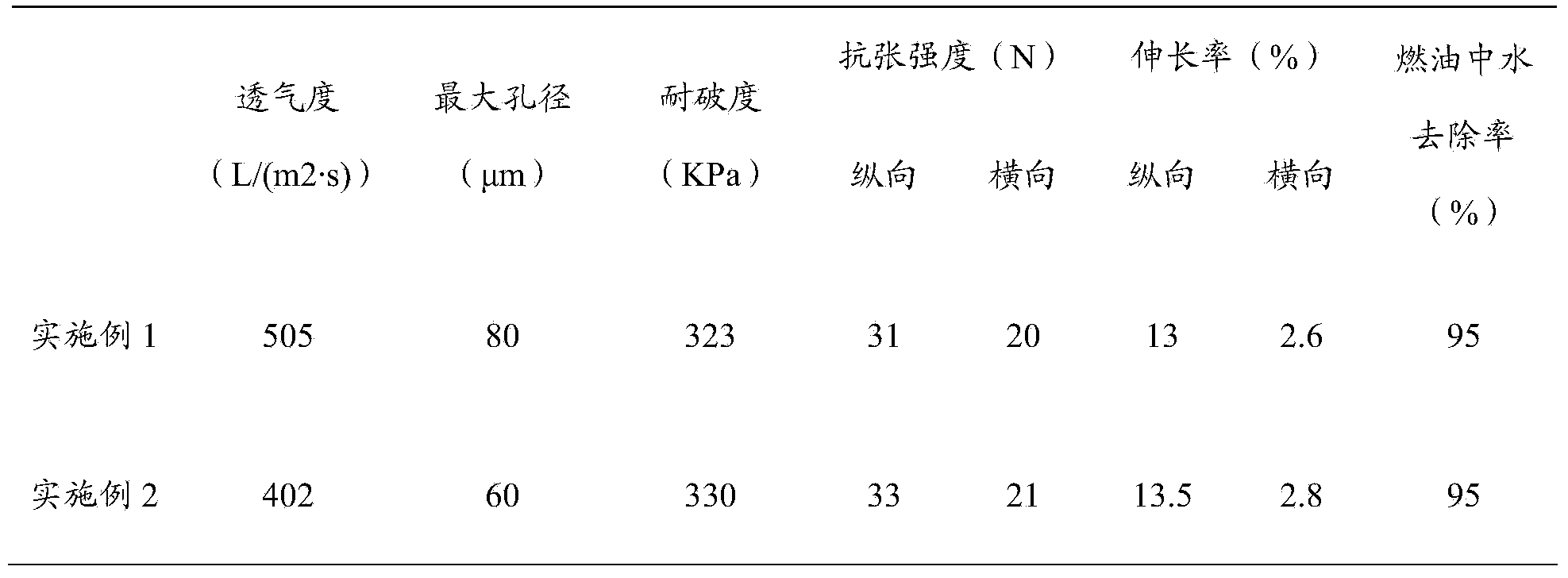

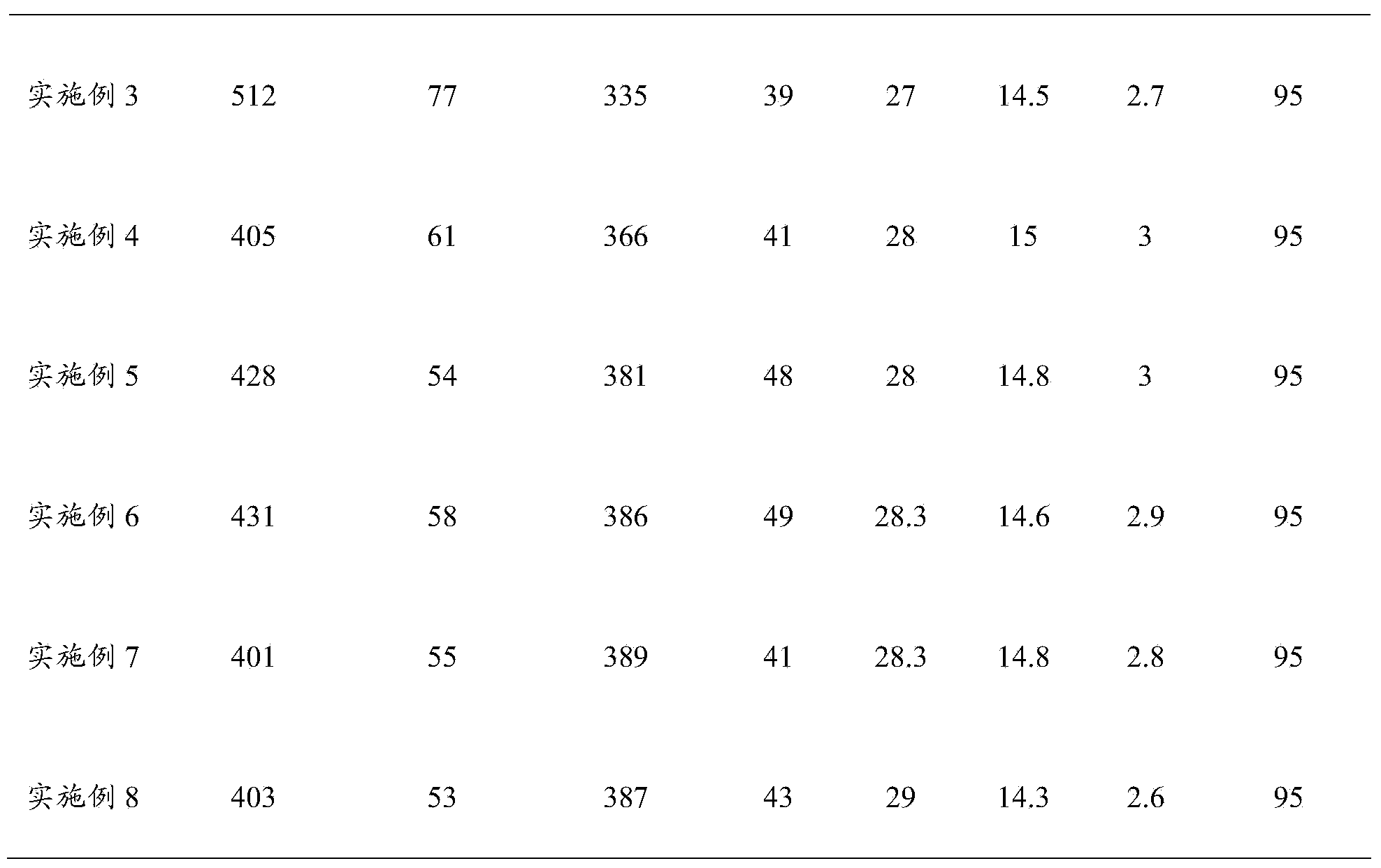

[0043] Perform a performance test on the fuel filter paper obtained in 1.2, and the test results are shown in Table 1. The paper strength of fuel filter paper is measured according to the national standard GB / T453-2002; the burst resistance is measured according to the national standard GB / T453-2...

Embodiment 2

[0045] 2.1 Base paper basis weight is 96g / m2, fuel oil filter paper weight is 118g / m2, mix 28% American southern pine softwood pulp, 17% Brazilian eucalyptus hardwood pulp, 36.3% polyester fiber and 0.1% PAE wet strength agent Mix pulp, after papermaking, get wet paper. The polyester fiber has a diameter of 12.8 μm and a length of 4 mm.

[0046] 2.2 Place the wet paper obtained in 2.1 on the inclined wire paper machine at a machine speed of 50m / min. When the dryness of the paper is 96%, use 18.6% acrylic resin for film transfer coating, and press it when the dryness reaches 85%. The embossing roll has a tooth height of 2.2 mm to obtain a fuel filter paper.

[0047] Perform a performance test on the fuel filter paper obtained in 2.2, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com