High-performance parachute rope and production method thereof

A manufacturing method and parachute technology, applied in the field of ropes, can solve problems such as small elongation unevenness and potential safety hazards, and achieve the effects of excellent impact resistance, excellent chemical corrosion resistance, and superior wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of this high-performance parachute parachute is realized through the following steps:

[0019] 1. Material selection: select multiple ultra-high molecular weight polyethylene fiber filaments with surface treatment specifications of 1000D-3000D;

[0020] 2. Paralleling: 6 ultra-high molecular weight polyethylene fibers are combined into one strand;

[0021] 3. Twisted yarn: The UHMWPE filaments after paralleling are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its rotational speed and twist are measured regularly , the twist depends on the size of the rope strands;

[0022] 4. Pre-weaving: The strands twisted by the twisting machine are pre-woven on the automatic pre-looming machine into a bobbin that meets the spindle size of the high-speed weaving machine for weaving;

Embodiment 1

[0025] (1) Material selection: select a number of 1000D ultra-high molecular weight polyethylene fiber filaments with surface treatment specifications;

[0026] (2) Paralleling: 6 ultra-high molecular weight polyethylene fibers are combined into one strand;

[0027] (3) Twisted yarn: the paralleled UHMWPE fiber filaments are twisted by a twisting machine, and each filament is controlled by a tension regulator, and its rotational speed and twist are measured regularly;

[0028] (4) Pre-weaving: The strands twisted by the twisting machine are pre-woven on the automatic pre-loom into a bobbin conforming to the spindle size of the high-speed weaving machine for weaving;

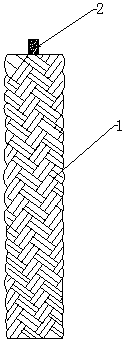

[0029] (5) Rope formation: The three strands of high-strength and high-elasticity nylon fiber treated by steam heat setting is the rope core 2, and the 16 bundles of ultra-high molecular weight polyethylene fiber strands are S-twisted, and the 16 bundles of ultra-high molecular weight polyethylene fiber ropes Th...

Embodiment 2

[0031] (1) Material selection: select a number of 1500D ultra-high molecular weight polyethylene fiber filaments with surface treatment specifications;

[0032] (2) Paralleling: 6 ultra-high molecular weight polyethylene fibers are combined into one strand;

[0033] (3) Twisted yarn: the paralleled UHMWPE fiber filaments are twisted by a twisting machine, and each filament is controlled by a tension regulator, and its rotational speed and twist are measured regularly;

[0034] (4) Pre-weaving: The strands twisted by the twisting machine are pre-woven on the automatic pre-loom into a bobbin conforming to the spindle size of the high-speed weaving machine for weaving;

[0035] (5) The three strands of high-strength and high-elasticity nylon fiber after steam heat setting treatment is the rope core 2, according to the S twist direction of 24 bundles of ultra-high molecular weight polyethylene fiber strands, and the Z twist direction of 24 bundles of ultra-high molecular weight po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com