Preparation method of silk fibroin/hyaluronic acid composite nanofiber loaded with vitamin C

A technology of composite nanofibers and silk fibroin, applied in cellulose/protein conjugated rayon, fiber processing, rayon manufacturing, etc., can solve the problem that natural proteins cannot simulate extracellular matrix components, and achieve strong application value , High viscoelasticity and water retention effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of silk fibroin:

[0030] First add 100 grams of cocoons to 1 liter of 0.5w / v% Na 2 CO 3 Boiling in an aqueous solution for 30 minutes, repeating the treatment three times, fully washing with distilled water, and drying in a drying oven at 45° C. to obtain degummed silk fibers. with CaCl 2 :C 2 h 5 OH:H 2 A ternary solvent was prepared at a molar ratio of O=1:2:8, and the silk fiber was hydrolyzed in a water bath at 70°C for 1 hour at a constant temperature at a bath ratio of 1:10 to obtain a completely dissolved brown-yellow silk fiber hydrolysis solution. Put the hydrolysis solution into a dialysis bag, dialyze with distilled water for 72 hours, put the dialyzed silk fiber hydrolysis solution in -80°C for 12 hours, and then freeze-dry it at -58°C until dry to obtain white, loose and porous silk fibroin .

Embodiment 2

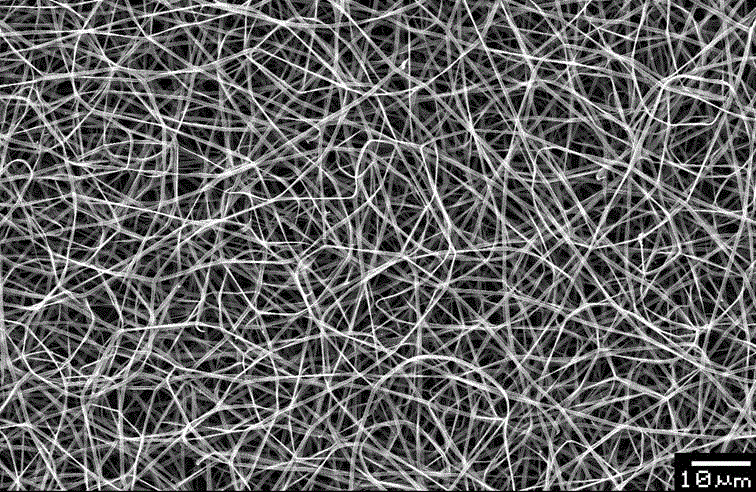

[0032] 4.29 grams of silk fibroin prepared in Example 1 were dissolved in 10 milliliters of deionized water (the density of deionized water was 1.0 g / cm 3 , the same below), stir until completely dissolved, and obtain a silk fibroin solution with a mass fraction of 30%; dissolve 0.42 g of hyaluronic acid in 10 ml of deionized water, stir until completely dissolved, and obtain a transparent silk fibroin solution with a mass fraction of 4%. Hyaluronic acid solution, mix 8 grams of silk fibroin solution with 2 grams of hyaluronic acid solution, so that the mass ratio of the two solutions is 8:2, then add 0.05 grams of vitamin C sodium phosphate in the mixed solution and stir evenly, then Carry out electrospinning, spinning condition is voltage 20 kilovolts, receiving distance 150 millimeters, spinning rate 0.5 milliliters / hour, obtains the composite nanofiber membrane that average fiber diameter is 512 ± 123 nanometers, composite nanofiber membrane photo is as follows figure 1 As...

Embodiment 3

[0034] Dissolve 4.29 grams of silk fibroin prepared in Example 1 in 10 milliliters of deionized water, stir until completely dissolved, and obtain a silk fibroin solution with a mass fraction of 30%; dissolve 0.42 grams of hyaluronic acid in 10 milliliters of deionized water, Stir until completely dissolved to obtain a hyaluronic acid solution with a mass fraction of 4%. Mix 8 grams of silk fibroin solution with 2 grams of hyaluronic acid solution so that the mass ratio of the two solutions is 8:2. Add 0.2 gram of vitamin C sodium phosphate and stir evenly, then carry out electrospinning, the spinning condition is voltage 20 kilovolts, receiving distance 150 millimeters, spinning speed 0.5 milliliters / hour, obtains the average fiber diameter and is 532 ± 104 nanometers Composite nanofiber membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com