Blue colorant and coloring method for aluminum material

A technology of blue colorant and aluminum material, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of affecting the surface color of aluminum products, surface color fading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

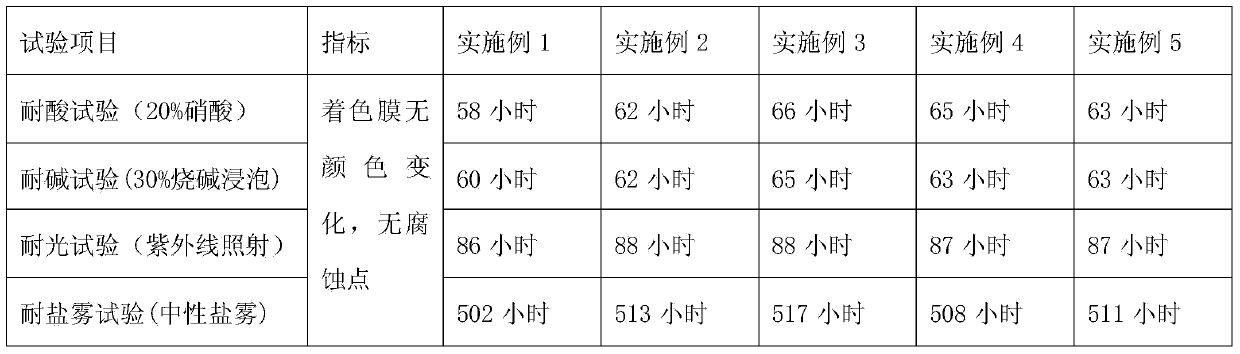

Examples

Embodiment 1

[0019] A kind of aluminum material blue coloring agent, comprises by weight component:

[0020] Liquid A: 30 parts of ammonium molybdate, 800 parts of water;

[0021] Liquid B: 30 parts of sulfuric acid, 8 parts of phosphoric acid, 10 parts of stannous sulfate, 10 parts of cresolsulfonic acid, 5 parts of sulfanilic acid, 2 parts of citric acid, and 800 parts of water.

[0022] The coloring method of the above-mentioned aluminum material blue colorant is carried out according to the following steps:

[0023] (1) Degreasing and cleaning: use metal degreaser to remove oil stains on the metal surface, and clean with 70°C pure water;

[0024] (2) Polishing: Physical or chemical polishing of the metal surface;

[0025] (3) Degreasing and cleaning: repeat step (1) for processing;

[0026] (4) Coloring: In 18% sulfuric acid electrolyte, at 20°C, the current density is 1-3 amps / dm 2 Under certain conditions, use direct current electrolysis for 20 minutes to form anodic oxide film, ...

Embodiment 2

[0029] A kind of aluminum material blue coloring agent, comprises by weight component:

[0030] Liquid A: 35 parts of ammonium molybdate, 850 parts of water;

[0031] Liquid B: 32 parts of sulfuric acid, 10 parts of phosphoric acid, 12 parts of stannous sulfate, 11 parts of cresolsulfonic acid, 6 parts of sulfanilic acid, 3 parts of citric acid, and 900 parts of water.

[0032] The coloring method of the above-mentioned aluminum material blue colorant is carried out according to the following steps:

[0033] (1) Degreasing and cleaning: Use a metal degreaser to remove oil stains on the metal surface, and clean with 75°C pure water;

[0034] (2) Polishing: Physical or chemical polishing of the metal surface;

[0035] (3) Degreasing and cleaning: repeat step (1) for processing;

[0036] (4) Coloring: In 19% sulfuric acid electrolyte, at 22°C, the current density is 1-3 amps / dm 2 Under the condition, use direct current electrolysis for 22 minutes to form anodic oxide film, th...

Embodiment 3

[0039] A kind of aluminum material blue coloring agent, comprises by weight component:

[0040] Liquid A: 36 parts of ammonium molybdate, 900 parts of water;

[0041] Liquid B: 35 parts of sulfuric acid, 12 parts of phosphoric acid, 13 parts of stannous sulfate, 12 parts of cresolsulfonic acid, 8 parts of sulfanilic acid, 4 parts of citric acid, and 950 parts of water.

[0042] The coloring method of the above-mentioned aluminum material blue colorant is carried out according to the following steps:

[0043] (1) Degreasing and cleaning: Use metal degreaser to remove oil stains on the metal surface, and clean with 80°C pure water;

[0044] (2) Polishing: Physical or chemical polishing of the metal surface;

[0045] (3) Degreasing and cleaning: repeat step (1) for processing;

[0046] (4) Coloring: In 20% sulfuric acid electrolyte, at 25°C, the current density is 1-3 amps / dm 2 Under certain conditions, use direct current electrolysis for 25 minutes to form anodic oxide film,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com