Preparation method of solvent-free waterborne polyurethane resin

A water-based polyurethane, solvent-free technology, applied in the field of polymer materials, can solve the problems of unfavorable dispersion, general wear resistance, low product strength, etc., to improve compatibility and adhesion, good water-based, good resistance abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

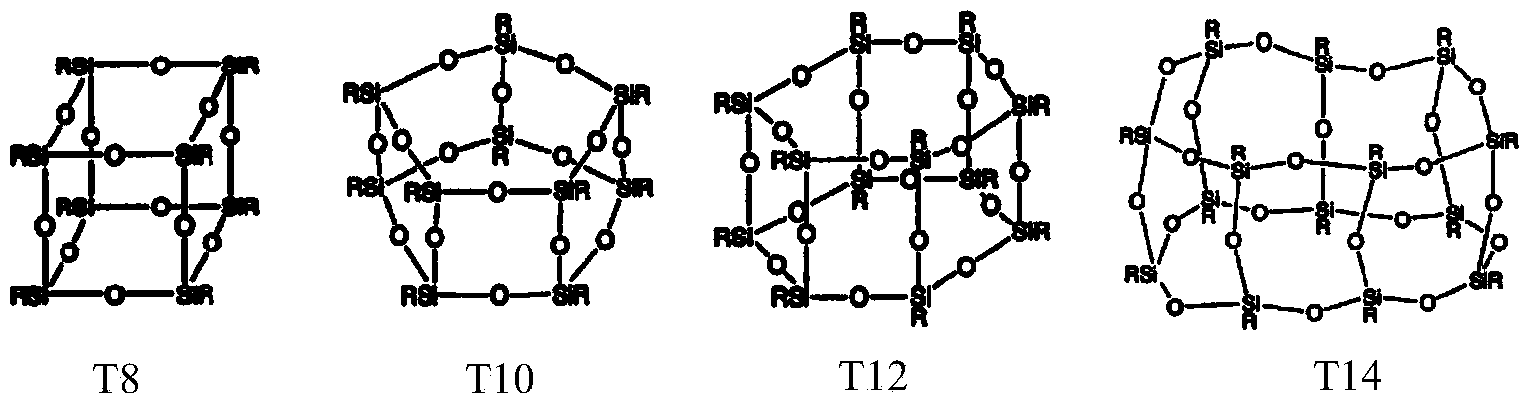

[0037] At 70°C, add 88.00g of amino cage silsesquioxane T8 to 191.00g of toluene diisocyanate, and after the reaction is clear, add 48.00g of 2,2-dimethylolbutoxy Ethylene glycol (20EO) methyl ether (ethoxy-terminated polymer diol, as shown in formula (I), wherein n=20), 200.00 g of polyglycol 1000, 19.20 g of dimethylolpropane Acid and 1.76g of catalyst di-n-butyltin dilaurate were reacted at 60°C for 2h; then the temperature was raised to 85°C to continue the reaction for 2h and then lowered to room temperature, and then 8.43g of neutralizing agent ammonia water and 890.00g of deionized water were added to it. After dispersing for 5 minutes, 40.68 g of ethylenediamine was added at 40° C. to carry out chain extension reaction for 3 hours, and cooled to room temperature to obtain waterborne polyurethane.

[0038] The conditions and parameters of the reaction process of Examples 2-9 are shown in Table 1 below.

[0039] Each step reaction condition and parameter of table 1 embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com