Preparation method of large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate

A technology of calcium methylthiobutyrate and methylthiobutyric acid, which is applied in the chemical industry, can solve the problems of nutrient damage, high price, and long drying time, so as to avoid emissions, save energy, and increase the total yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

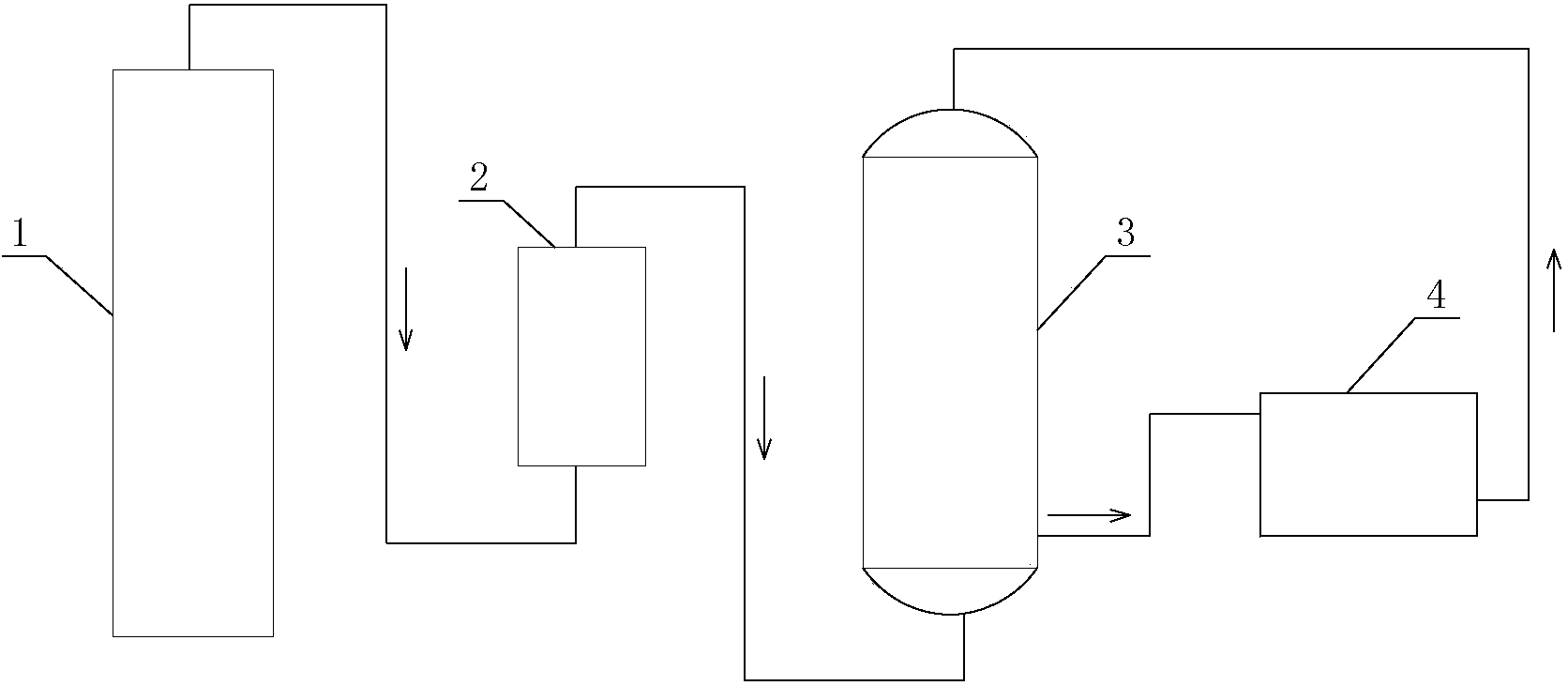

Image

Examples

Embodiment 1

[0052] Dilute 340.9g of 2-hydroxy-4-methylthiobutyric acid from 88% to 40% with deionized water, then add 0.015g of lactic acid, stir and heat to 60°C, keep warm for 60 minutes, add anhydrous calcium chloride solid 111 g, during the reaction, the pH of the reaction system was adjusted to 6.0 with sodium hydroxide, and the reaction was stirred at a constant temperature for 2 hours. After the reaction was completed, cool to 10°C and press filter to obtain white crystals, which were washed twice with a small amount of cold water, and then vacuum-dried to constant weight at 90°C to obtain 331.1 g of calcium 2-hydroxy-4-methylthiobutyrate with a purity of It was 98%, and the yield was 96%. Analysis results: 2-hydroxy-4-methylthiobutyric acid content 86.2%; calcium: 11.3%; water content: 0.5%; purity 98%; 140 mesh analysis sieve 85%, in the form of smooth powder with crystals Sexual luster, bulk density (g / cm) is 0.69.

[0053] Add water to the obtained 2-hydroxy-4-methylthiobutyr...

Embodiment 2

[0055] Dilute 340.9g of 2-hydroxy-4-methylthiobutyric acid from 88% to 35% with deionized water, then add 0.034g of citric acid, stir and heat to 80°C, keep warm for 30 minutes, add anhydrous calcium chloride The solid was 111 g. During the reaction, the pH of the reaction system was adjusted to 7.0 with sodium hydroxide, and the reaction was stirred at a constant temperature for 2 hours. After the reaction was completed, cool to 10°C and press filter to obtain white crystals, which were washed twice with a small amount of cold water, and then vacuum-dried to constant weight at 90°C to obtain 331.1 g of calcium 2-hydroxy-4-methylthiobutyrate with a purity of It was 98%, and the yield was 96%. Analysis results: 2-hydroxy-4-methylthiobutyric acid content 86.2%; calcium: 11.3%; water content: 0.5%; purity 98%; 140 mesh analysis sieve 84%, in the form of smooth powder with crystals Sexual luster, bulk density (g / cm) is 0.70.

[0056] Add water and the recrystallization mother li...

Embodiment 3

[0058] Dilute 340.9g of 2-hydroxy-4-methylthiobutyric acid from 88% to 60% with deionized water, then add 0.014g of hydroxymethyl cellulose, stir and heat to 70°C, keep it warm for 30 minutes, add anhydrous Calcium carbonate solid 101g, during the reaction, adjust the pH of the reaction system with sodium hydroxide to maintain at 6.0, stir and react at constant temperature for 3 hours. After the reaction was completed, cool to 10°C and press filter to obtain white crystals, which were washed twice with a small amount of cold water, and then vacuum-dried to constant weight at 90°C to obtain 331.1 g of calcium 2-hydroxy-4-methylthiobutyrate with a purity of It was 98%, and the yield was 96%. Analysis results: 2-hydroxy-4-methylthiobutyric acid content 86.2%; calcium: 11.3%; water content: 0.5%; purity 98%; 140 mesh analysis sieve 86%, in the form of smooth powder with crystals Sexual luster, bulk density (g / cm) is 0.65.

[0059] Add water and the recrystallization mother liquo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com