Negative-ion eco-ceramic tile and preparation method thereof

A technology of negative ions and ceramic tiles, applied in the field of ceramic tiles, can solve the problem of low release of negative ions, and achieve the effects of reducing production costs, long service life and natural texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

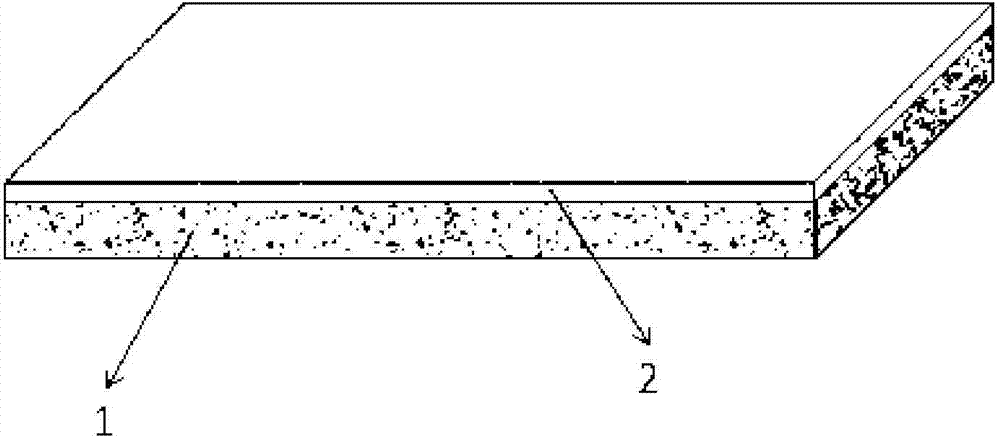

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a kind of negative ion ecological ceramic tile comprising: the bottom layer of ceramic body, the surface layer of negative ion glaze layer, and described negative ion glaze layer comprises the component of following weight percent: potassium feldspar 30%-35% %, albite 15%-30%, diatomite 25%-30%, clay 3%-20%, quartz 5%-10%, and indium-containing high-temperature-resistant rare earth composite powder 3%-8%.

[0028] As the "air vitamin" in the medical field, negative ions have significant functions of sterilization, disinfection, deodorization, anticorrosion, dust reduction, etc., and have been regarded as an important standard for evaluating the environment and air quality. Relevant data show that the concentration of negative ions in the building rooms is mostly 100 / cm 3 Below, it is easy to induce various human diseases. Using artificial methods to increase the concentration of negative ions ...

Embodiment 2

[0040] The embodiment of the present invention also provides a kind of preparation method of described negative ion ecological ceramic brick, and described preparation method is as follows:

[0041] Step 1: The weight percentages are respectively 30%-35% potassium feldspar, 15%-30% albite feldspar, 25%-30% diatomite, 3%-20% clay, 5%-10 % of quartz, 3%-8% of indium-containing high-temperature-resistant rare earth composite material powder, 1% of cellulose and an appropriate amount of defoamer are mixed and then added to a ball mill for ball milling, and then sieved to make negative ion glaze slurry;

[0042]During the firing process of the glaze, a certain amount of gas will be generated due to various reasons, resulting in air bubbles in the glaze, which will easily cause pinholes, unevenness and other defects on the glazed surface of ceramic tiles, which will affect the appearance. In the embodiment of the present invention, adding a defoamer can avoid the generation of air b...

Embodiment 3

[0052] Step 1: Preparation of negative ion glaze slurry: 30% potassium feldspar, 20% albite feldspar, 25% diatomaceous earth, 8% clay, 5% quartz, and high temperature resistant rare earth composite material powder containing 0.03% indium by mass 5%, 1% cellulose, appropriate amount of water, and appropriate amount of antifoaming agent are mixed, then added to the ball mill and milled for 4 hours, and then sieved to make negative ion glaze slurry;

[0053] Step 2: Glaze the surface of the ceramic body by pressing glaze, and then press the glazed ceramic body to form, dry, and bleed;

[0054] Step 3: Put the semi-finished ceramic tiles after infiltration into the tunnel kiln for firing. The firing temperature is 1100°C, and the firing time in the high temperature zone is 40 minutes. After cooling, polish the obtained ceramic glazed tiles and perform related post-processing , Obtain the anion ecological ceramic brick of the embodiment of the present invention.

[0055] The thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com