High-dielectric-constant lithium-niobium-titanium-based low-temperature-fired ceramics and preparation method thereof

A high-dielectric constant, low-temperature sintering technology, applied in the field of dielectric ceramics, can solve the problems of high viscosity of slurry, inability to co-firing, and high sintering temperature, and achieve a low resonant frequency temperature coefficient, moderate quality factor Qf, and reduced sintering temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

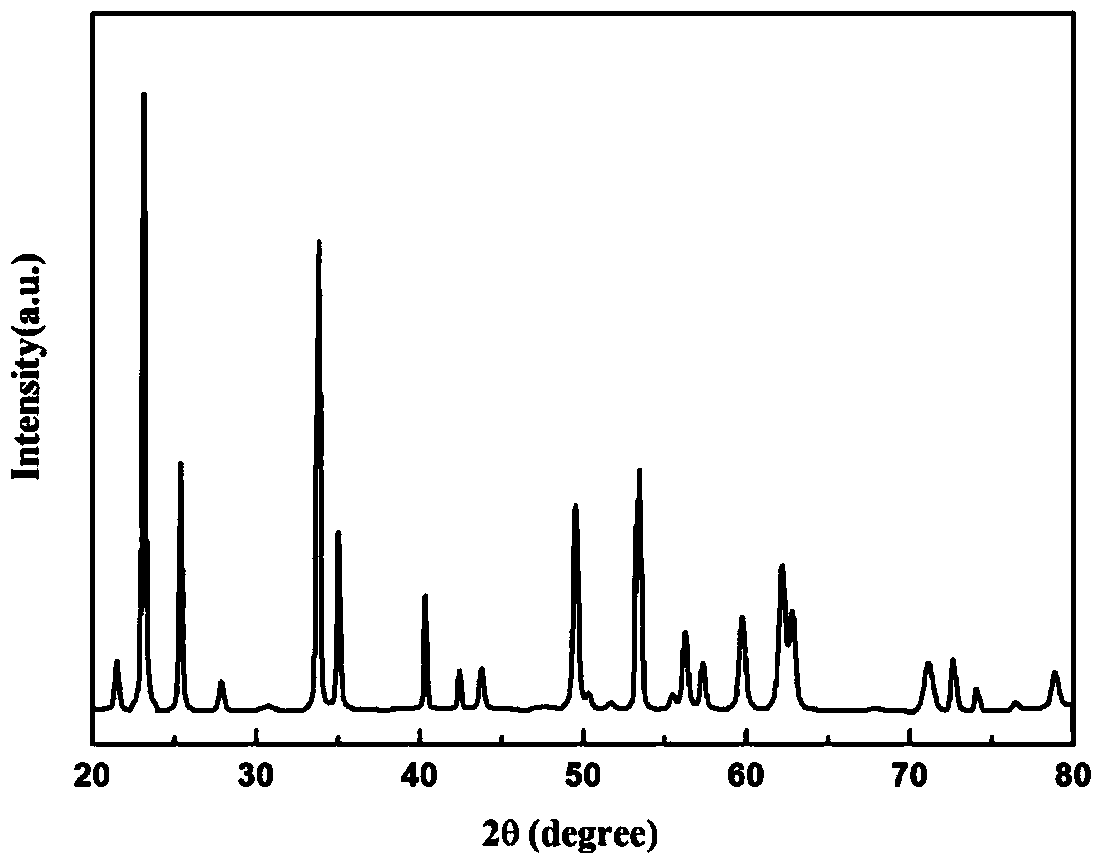

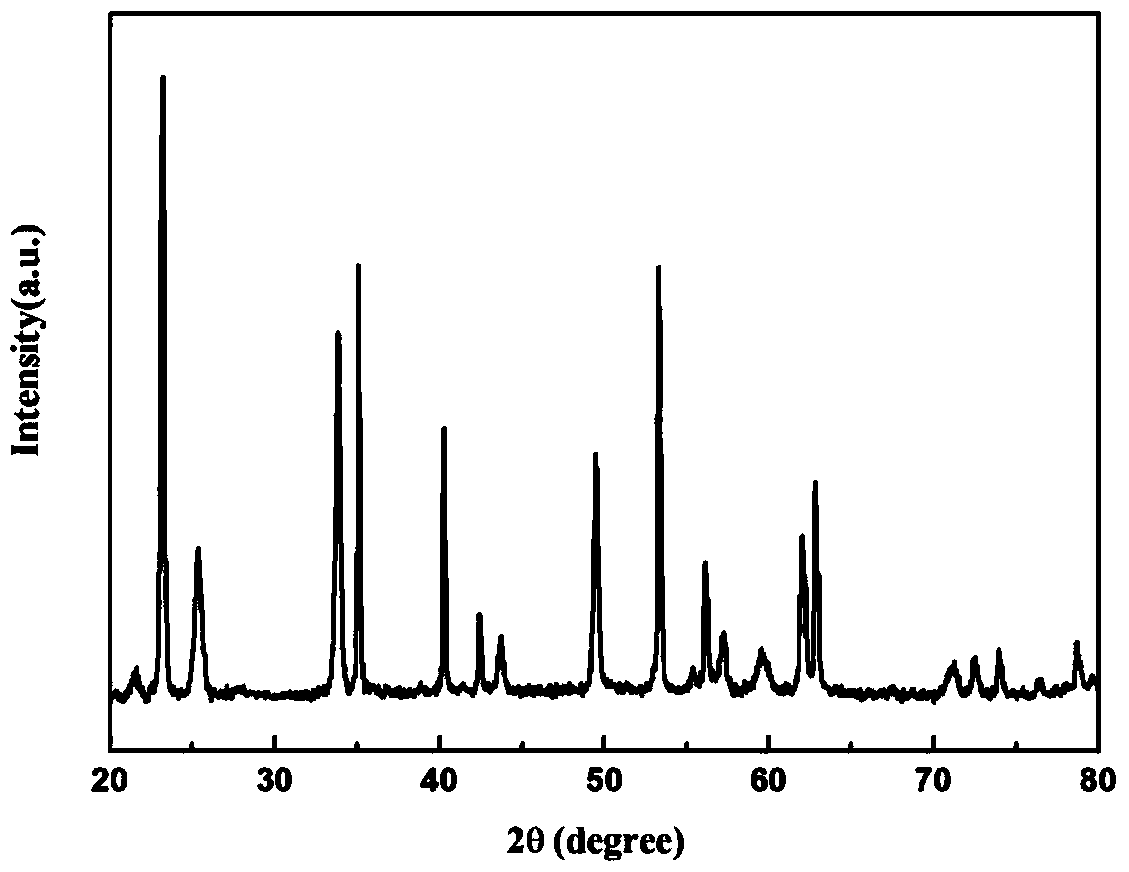

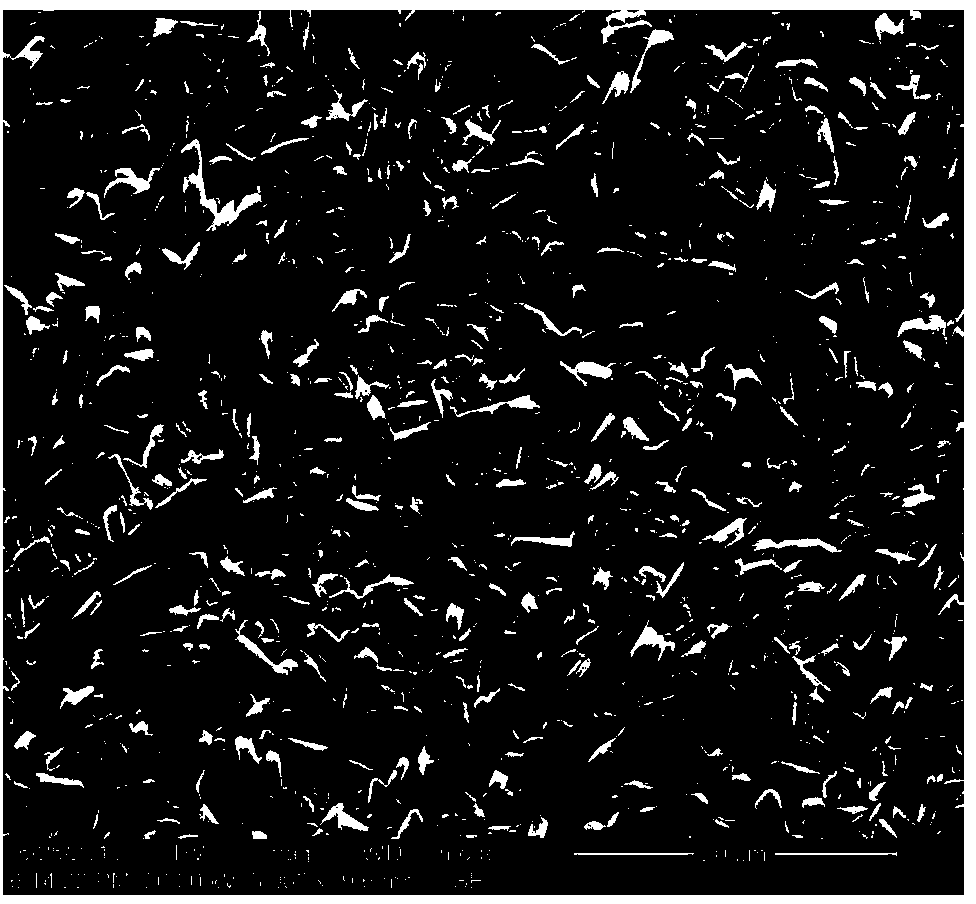

[0030] The material of the invention is composed of a lithium-rich lithium-niobium-titanium series material and a lithium borosilicate glass fever reducer accounting for 1-10% by weight of the main crystal phase. The composition of lithium-rich lithium-niobium-titanium series materials is Li 1.0+x Nb 0.6 Ti 0.5 o 3 -yLBS, wherein: LBS is lithium borosilicate glass fever reducer, 0≤x≤0.2 (molar ratio), 0≤y≤0.1 (weight ratio). The raw materials for the manufacture of LBS contain: lithium carbonate (Li 2 CO 3 ), silicon dioxide (SiO 2 ) and boron trioxide (B 2 o 3 ). Table 1 shows the data of several specific examples of the composition content of the present invention, and Table 2 shows the microwave dielectric properties of each example. The evaluation of microwave dielectric properties is carried out by cylindrical dielectric resonator method, and the detection method is GB / T7265.2-1987 open cavity method.

[0031] Its preparation method:

[0032] Step 1: lithium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com