Electromagnetic type muddy water separating tower and electromagnetic type muddy water separating method

一种泥水分离塔、电磁式的技术,应用在浓缩领域,能够解决降低出水SS、成本高、不符合排放标准等问题,达到通用性好、运行稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

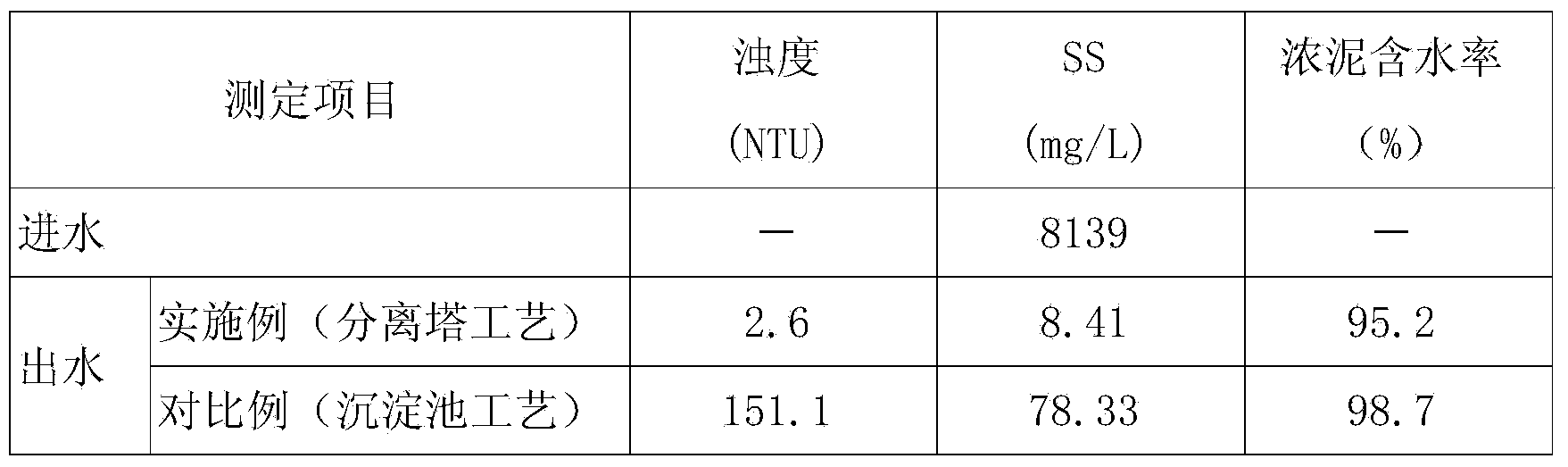

[0030] Embodiment: After being treated with an electromagnetic mud-water separation tower, SS≤10mg / L, turbidity≤5NTU, the main indicators all meet the conventional requirements for water quality testing of sedimentation tanks in water supply enterprises, and can be recycled for production water systems, and the moisture content of concentrated mud It can reach 95%, and the water content and flow rate are relatively stable during the continuous sludge discharge process.

[0031] The water quality and related parameters before and after the two different processes are shown in Table 1.

[0032] Table 1

[0033]

[0034] See Table 2 for the comparison of the main parameters of the examples and comparative examples for various muddy water treatment amounts.

[0035] Table 2

[0036]

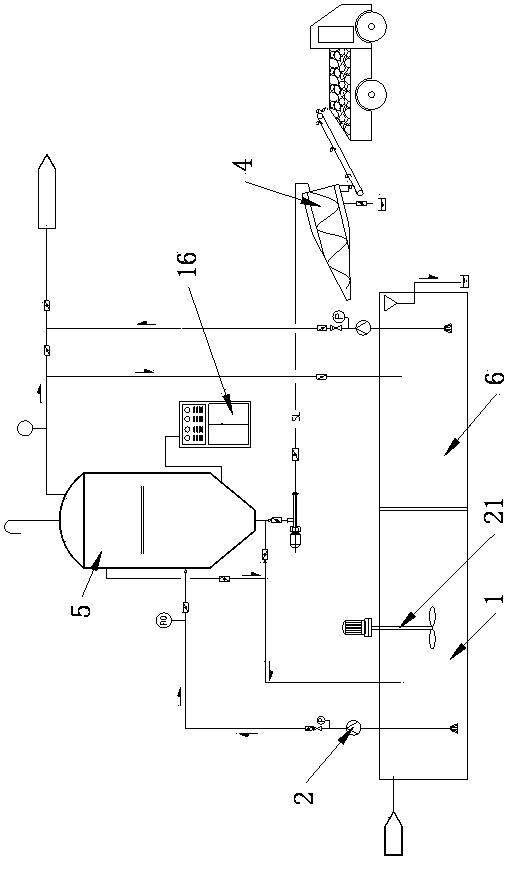

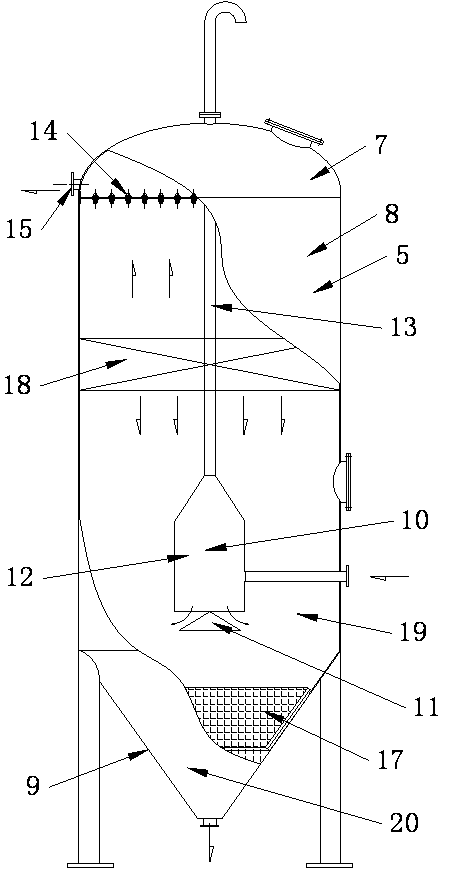

[0037] A method and device disclosed in the present invention that can be widely used in the treatment of muddy water produced in the production process of water supply enterprises: an electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com