Production line and process for refractory materials

A refractory material and production line technology, which is applied in the field of refractory materials, can solve the problems of high failure rate of mechanical equipment, lower batching accuracy, and easy dusting, etc., and achieve the effects of convenient disassembly and arrangement, improved batching accuracy, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

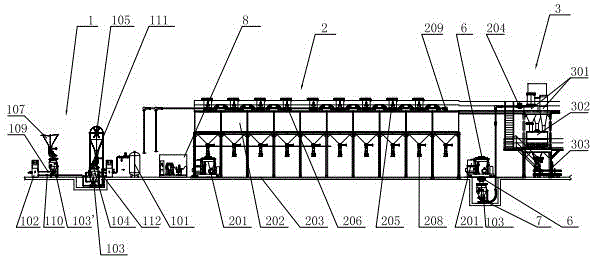

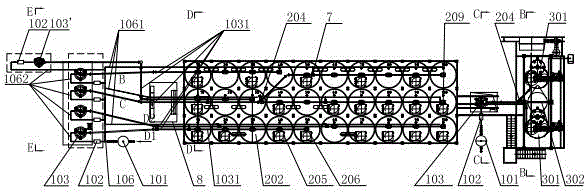

[0040] Such as figure 1 , figure 2 As shown, a production line for refractory materials includes a feeding unit 1, a batching unit 2, and a mixing and packaging unit 3;

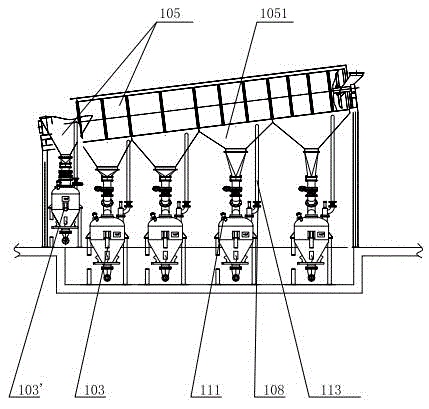

[0041] The feeding unit 1 includes an air storage tank 101, the air storage tank 101 is connected to an external compressed air station (not shown in the figure), through which air is supplied to the air storage tank 101, and the air storage tank 101 is connected to an air supply pipeline 106 , the first air supply pipeline 1061 and the second air supply pipeline 1062 are formed in parallel on the air supply pipeline 106, the first air supply pipeline 1061 enters the batching unit 2, and each second air supply pipeline 1062 is connected to the second air supply pipeline through the first electric control cabinet 102 One sending tank 103 and the second sending tank 103'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com