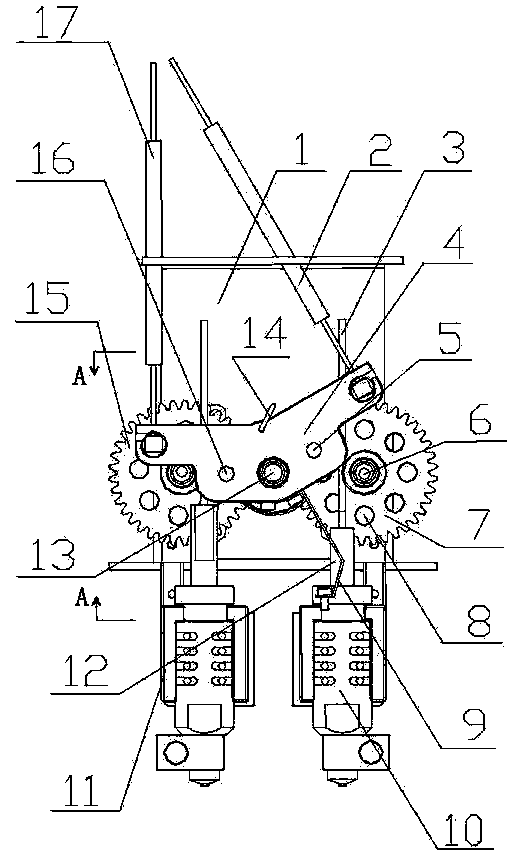

Single-motor double printer head 3D printer head mechanism

A 3D printer and dual nozzle technology, applied in printing and other directions, can solve the problems of high torque waste, heavy dual motors, hidden dangers of printing multi-color, etc., and achieve the effect of convenient operation, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

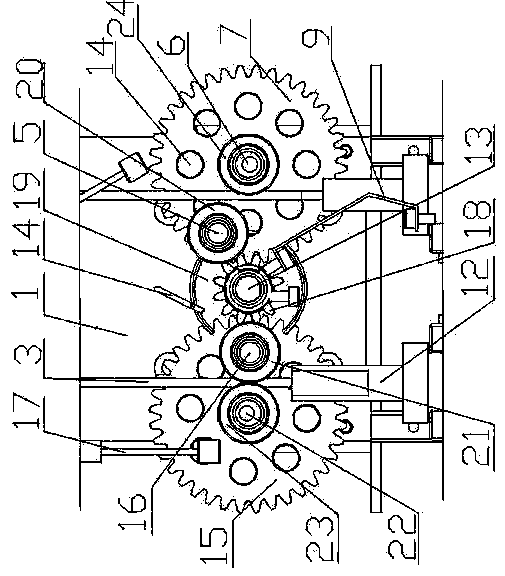

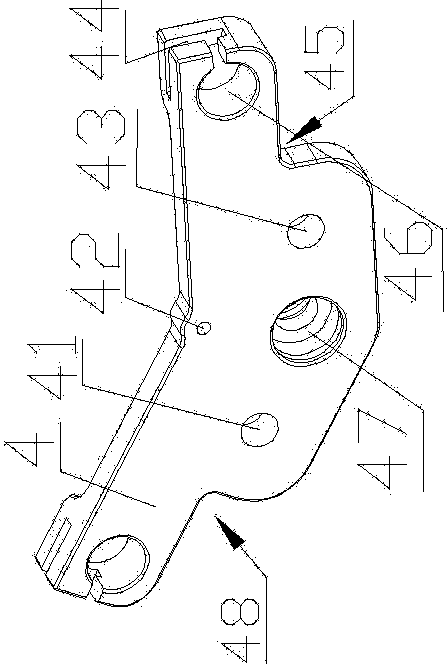

[0020] The present invention is equipped with motor 19 at nose frame 1, and driving gear 18 is installed on the motor shaft 13 of motor 19, and driving gear 18 meshes with left large gear 15, right large gear 7 simultaneously, and the left gear shaft 22 of left large gear 15 And the right gear axle 6 of right bull gear 7 is fixed on the headstock 1, in order to facilitate the rotation of two bull gears, upper bearing can be installed between respective gear and axle respectively. A tripod 4 is installed at the front end of the motor shaft 13, the left end of the tripod 4 is connected with a left stay wire 17, the right end is connected with a right stay wire 2, the left stay wire 17 and the right stay wire 2 are connected to an external motor, and the left stay wire or the right stay wire is pulled by the external motor , so that the tripod can swing left and right with the motor shaft as the center. The motor shaft 13 is inserted on the tripod 4 through the bearing in the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com