Double-metal mechanical composite pipe end inner wall surfacing device

A technology of composite pipe and bimetal, which is applied in the field of surfacing welding, can solve the problems of slow surfacing welding speed, high manufacturing cost, and large space occupied by frames and brackets, and achieve reduced workload, adjustable wire feeding speed, and improved surfacing welding. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

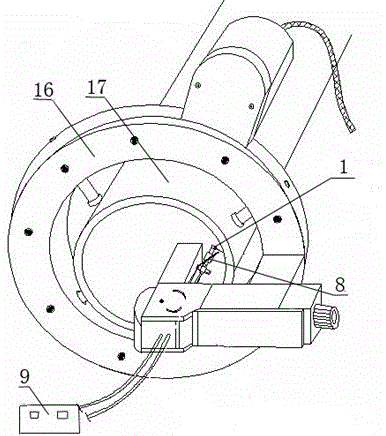

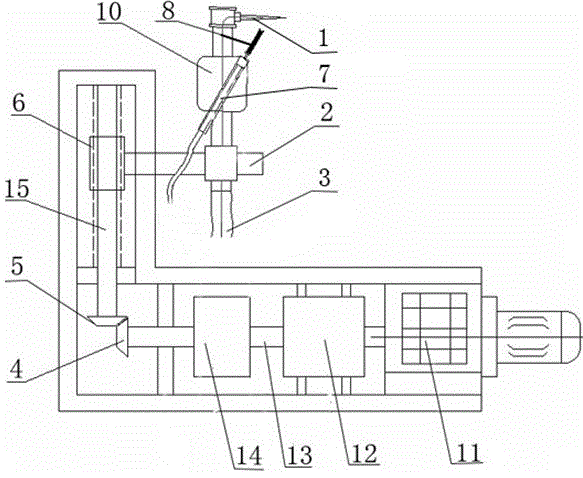

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

[0027] Such as figure 1 , figure 2 Shown, a kind of bimetal mechanical composite pipe end inner wall surfacing welding device, it comprises welding mechanism, described welding mechanism comprises welding torch 1, is used to adjust the welding torch adjusting rod 2 of welding torch 1 angle and is electrically connected with welding torch adjusting rod 2 Welding power supply 3; welding torch adjustment rod 2 can adjust the angle of welding torch 1 according to the aperture size of the pipe body 17 to be welded, so as to meet the requirements of surfacing welding thickness and the like.

[0028] Further, the welding torch lateral rotation mechanism includes a first drive mechanism and a second transmission mechanism, the first driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com