Square Hole Vacuum Casting Mold Components

A vacuum casting and mold technology, applied in the field of casting molds, can solve the problems of unstable filling process, affecting operation speed, affecting ingot performance, etc., to achieve uniform and stable filling process, improve processing performance, and reduce casting defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

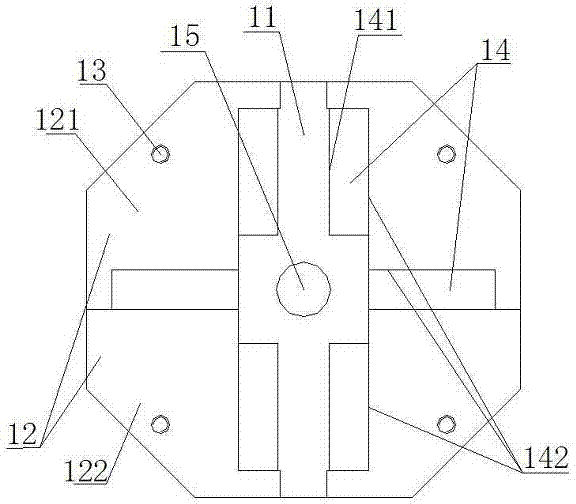

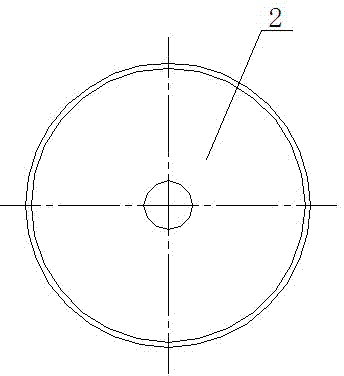

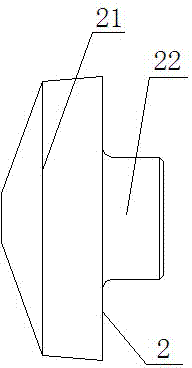

[0036] See Figure 1-Figure 10 , This embodiment includes: a mold main body 1, a graphite cover 2, a graphite ring 3, a casting cover 4, and a clamping frame 5; the mold main body 1 is composed of an inner mold 11 and four outer molds 12, four outer molds 12 surrounds the inner mold 11; the graphite cover 2 includes a head 21 and a handle 22, the handle 22 is fixed on the bottom surface of the head 21 and connected as a whole, the head 21 is a truncated cone structure; the inner mold 11 A central hole 15 with a diameter of 30mm is opened in the center, and the central hole 15 is a cylindrical through hole. The bottom surface of the head 21 of the graphite cover 2 is circular, and the bottom diameter of the head 21 is larger than the diameter of the central hole 15 , The outer diameter of the handle 22 is slightly smaller than the inner diameter of the central hole 15 and the handle 22 is clamped into the central hole 15; the graphite ring 3 is located on the mold main body 1, a...

Embodiment 2

[0045] See Picture 11 In this embodiment, the mold main body 1 is composed of an inner mold 11 and three outer molds 12. The three outer molds 12 surround the inner mold 11, and the three outer molds 12 have the same shape; There are three inner mold grooves 141 around 11, and an outer mold groove 142 is opened on each of the three outer molds. The inner mold groove 141 and the outer mold groove 142 are square and correspond to each other, forming a cross section Three cavities 14 are square, and the dimensions of the three cavities 14 are all 90mm×18mm; the vertical distances from the central hole 15 to the three cavities 14 are equal, and the three cavities 14 are symmetrically distributed and separated from each other. The distance is the same.

[0046] Other parts and assembly drawings of this embodiment are omitted. The structure of the graphite cover 2 and the graphite ring 3 of this embodiment is the same as that of the first embodiment. The outer peripheral shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com