Variable frequency speed regulating disk type motor and vacuum pump

A disc motor, frequency control technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, magnetic circuit static parts, etc., can solve the limitation of the use range of vacuum pumps, frequency control motors Unable to adapt to use requirements, unstable load capacity and other problems, to achieve the effect of improving electrical performance and starting performance, good low-frequency and low-speed operation characteristics, and improving power factor and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

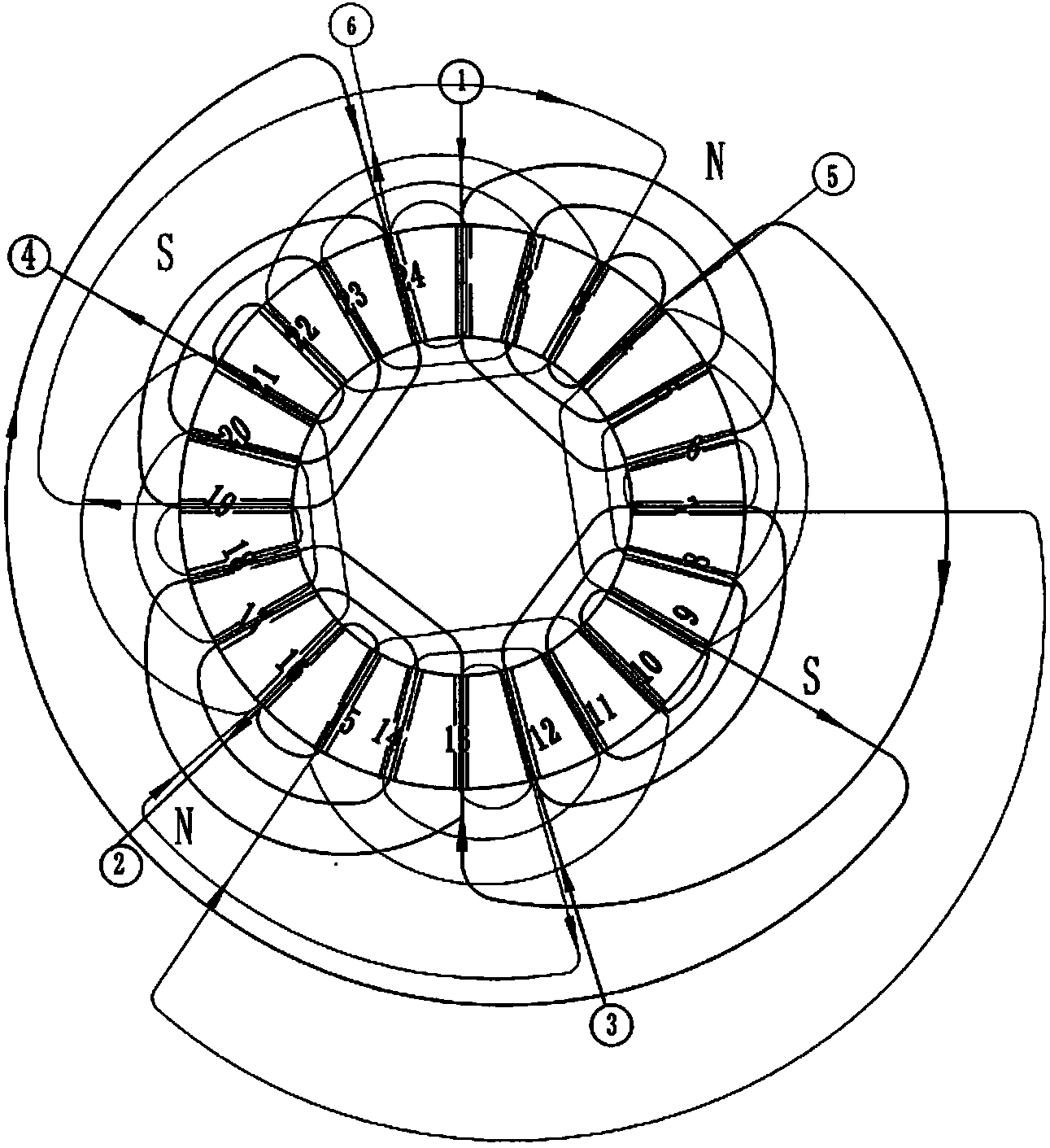

[0029] as attached figure 1 As shown, the frequency conversion speed regulating disc motor of the present invention includes a flat disc-shaped stator 11 and a rotor 13, and the described motor can be applied to a vacuum pump, and its installation in the vacuum pump is as follows: figure 1 As shown, the stator 11 and rotor 13 are directly embedded in the vacuum pump housing 10 for assembly, the air gap 12 between the stator and rotor can be adjusted, and the rotor 13 is a cast aluminum squirrel-cage rotor in a radial shape, and is fixedly installed On the transmission shaft 15 of the vacuum pump, the transmission shaft 15 is connected to the housing 10 through the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com